Cotton straw fulvic acid and cellulose ethyl alcohol production process

A technology of cellulosic ethanol and cotton stalks, which is applied in the field of comprehensive utilization of straw biomass resources, can solve the problems of greatly affecting accessibility and increasing the amount of cellulase preparations, so as to improve economic competitiveness, eliminate negative effects, and realize Effects of Circular Economy and Sustainable Development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] First, high-purity cellulose and fulvic acid are obtained through pretreatment.

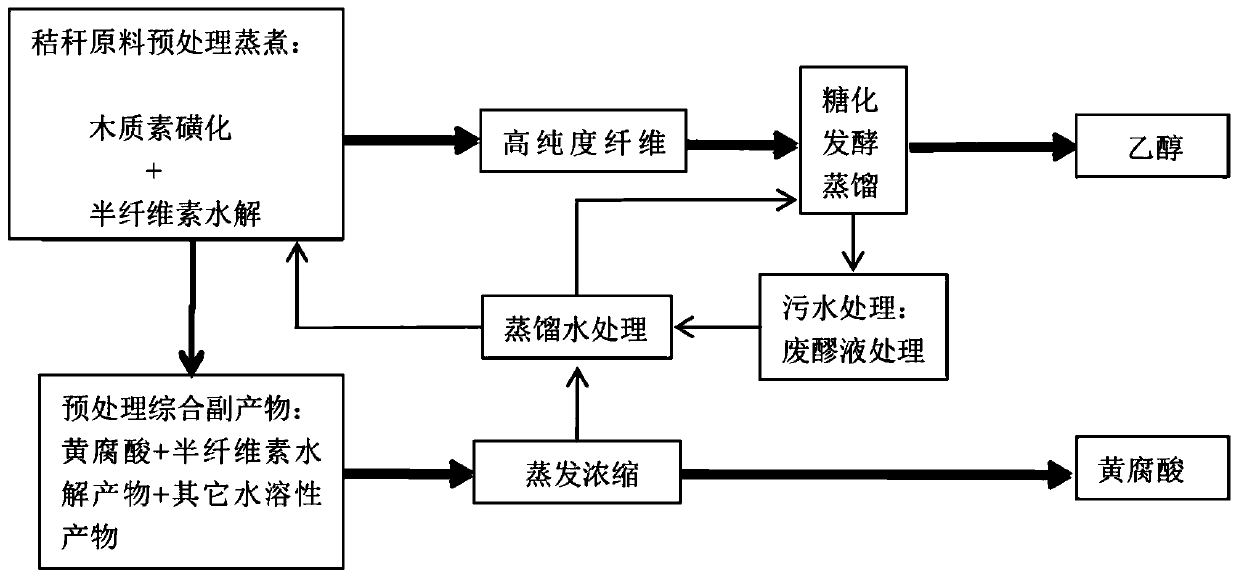

[0145] Cotton straw is pulped by acidic ammonium sulfite for fiber pretreatment, and the sequence is "material preparation - washing - cooking (complete hemicellulose hydrolysis and fulvic acid extraction) - spraying - squeezing - refining - extraction of fulvic acid Acid black liquor-screening-fiber classification-high-purity cellulose" process is completed, specifically:

[0146] (1) Prepare materials, take cotton straw from the tenth regiment of the first division of the Xinjiang Construction Corps, with a cellulose content of 42.35%, a lignin content of 24.52%, and a hemicellulose content of 18.31%, collect and pulverize the cotton straw to 10-20 cm, and transport it to the raw material warehouse Air-dried and stacked storage, keep the water content below 20%; according to the design feeding speed of 2 to 2.5 tons of soil-removed, impurity-removed and dry raw materials to produce one t...

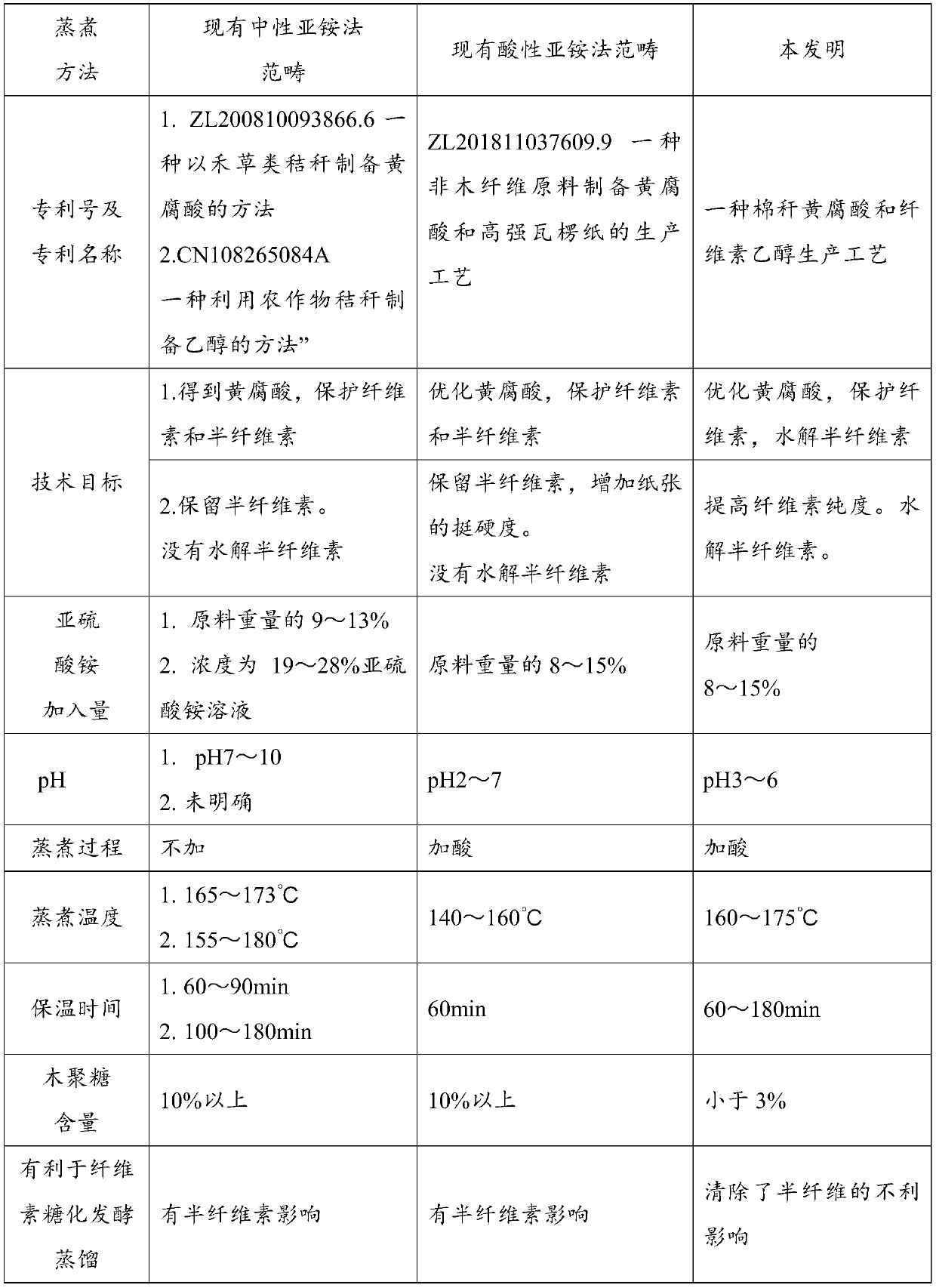

Embodiment 2

[0168] (1) pretreatment flow process is the same as embodiment 1

[0169] (2) Cooking, hemicellulose hydrolysis and fulvic acid extraction process are as follows: the amount of ammonium sulfite is 15% of the net weight of the raw material, the amount of acetic acid is 5% of the net weight of the raw material, the liquid ratio is 1:6, the pressure is 0.6-0.8Mpa, the temperature 160°C, holding time 150min, start cooking at pH 6.1, and finish cooking at pH 4.5.

[0170] (3) Obtain pretreated cellulose and fulvic acid. The xylan content in the cellulose is 2.9%, and the fulvic acid concentrated black liquor is sprayed and dried to obtain a fulvic acid dry powder, and the fulvic acid content is 41% (dry basis).

Embodiment 3

[0172] (1) The pretreatment process is the same as in Example 1.

[0173] (2) Cooking, hemicellulose hydrolysis and fulvic acid extraction process are as follows: the amount of ammonium sulfite is 15% of the net weight of raw materials, the amount of maleic acid is 0.4mol / L, the liquid ratio is 1:6, the temperature is 160°C, and the pressure is 0.6 ~0.8Mpa, holding time 150min, start cooking pH6.1, finish cooking pH5.2.

[0174] (3) obtain pretreated cellulose and fulvic acid, xylan content 1.9% in the cellulose, the thick black liquor of fulvic acid obtains fulvic acid dry powder by powder spraying drying, fulvic acid content 44% (dry basis ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com