Method for improving activated sludge concentration in alcohol wastewater full-distillage anaerobic digestion process

An activated sludge and anaerobic digestion technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low anaerobic operation efficiency, difficult sludge treatment, and high equipment investment problems, to achieve the effect of reducing emissions, reducing COD content, and achieving obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

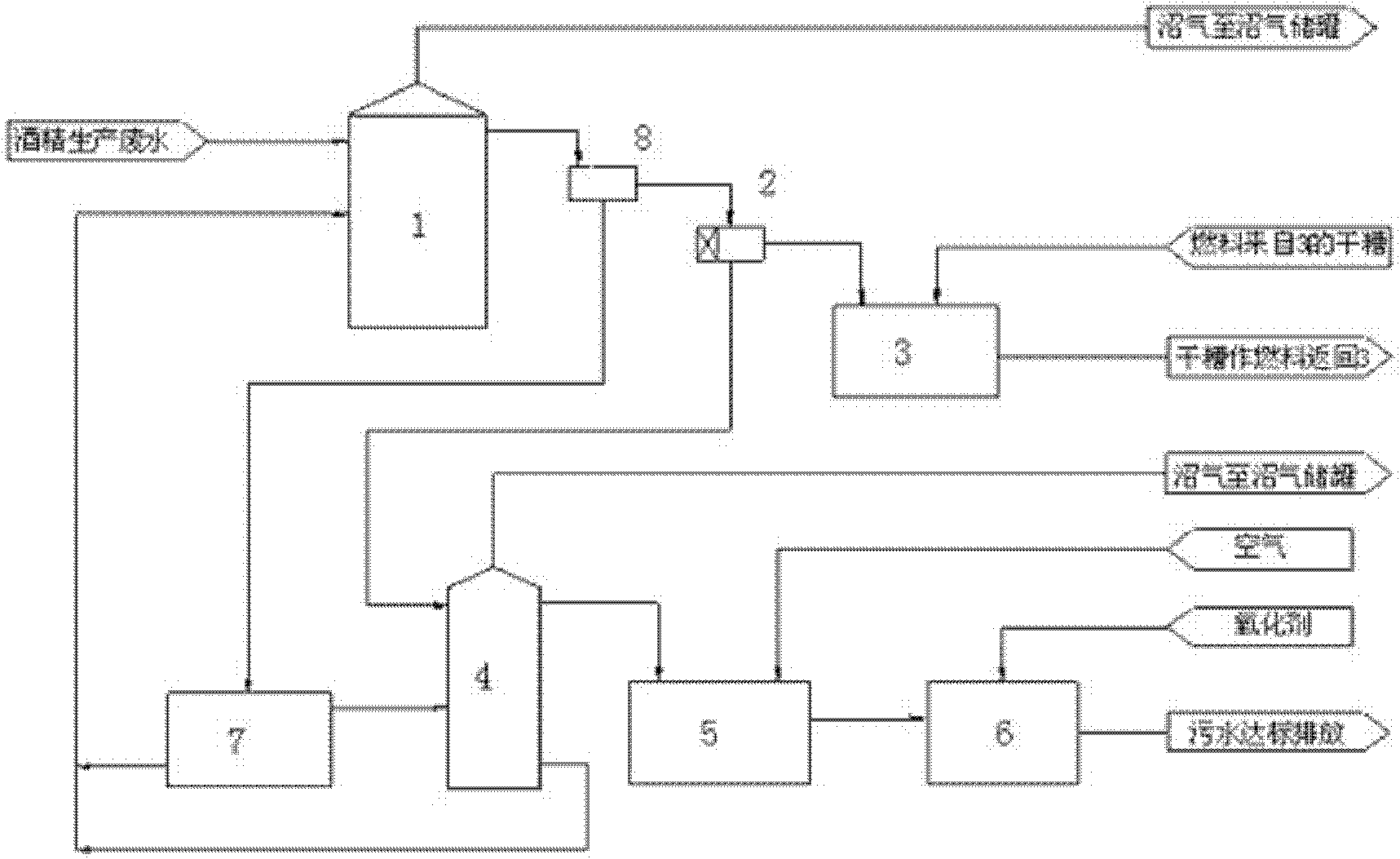

Image

Examples

Embodiment

[0023] Wastewater with a COD concentration of 60,000mg / L from the corn stalk alcohol production process is sent to the primary anaerobic tank 1, which is equipped with a heat exchanger to control the operating temperature of the primary anaerobic tank 1 to 60°C. The primary anaerobic tank 1 is a fully mixed high-temperature anaerobic reactor, and the volume load of wastewater anaerobic operation reaches 8.0kgCOD / m3.d. After anaerobic treatment of wastewater, COD is less than 6000mg / L first-level anaerobic water effluent, and the biogas generated by the first-level anaerobic operation is sent to the biogas storage tank. The methane purity in the biogas is 55%, and the returned activated sludge biogas part Anaerobic digestion increases the biogas production, and the primary anaerobic effluent containing a large amount of sludge discharged from the primary anaerobic tank 1 is sent to the activated sludge separation device 8 .

[0024]In the activated sludge separation device 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com