Alcohol production process

a technology of alcohol production and process, applied in the direction of biomass after-treatment, biofuels, specific use bioreactors/fermenters, etc., can solve the problem of reducing the supply of substrates, and achieve the effect of improving the overall efficiency of microbial fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

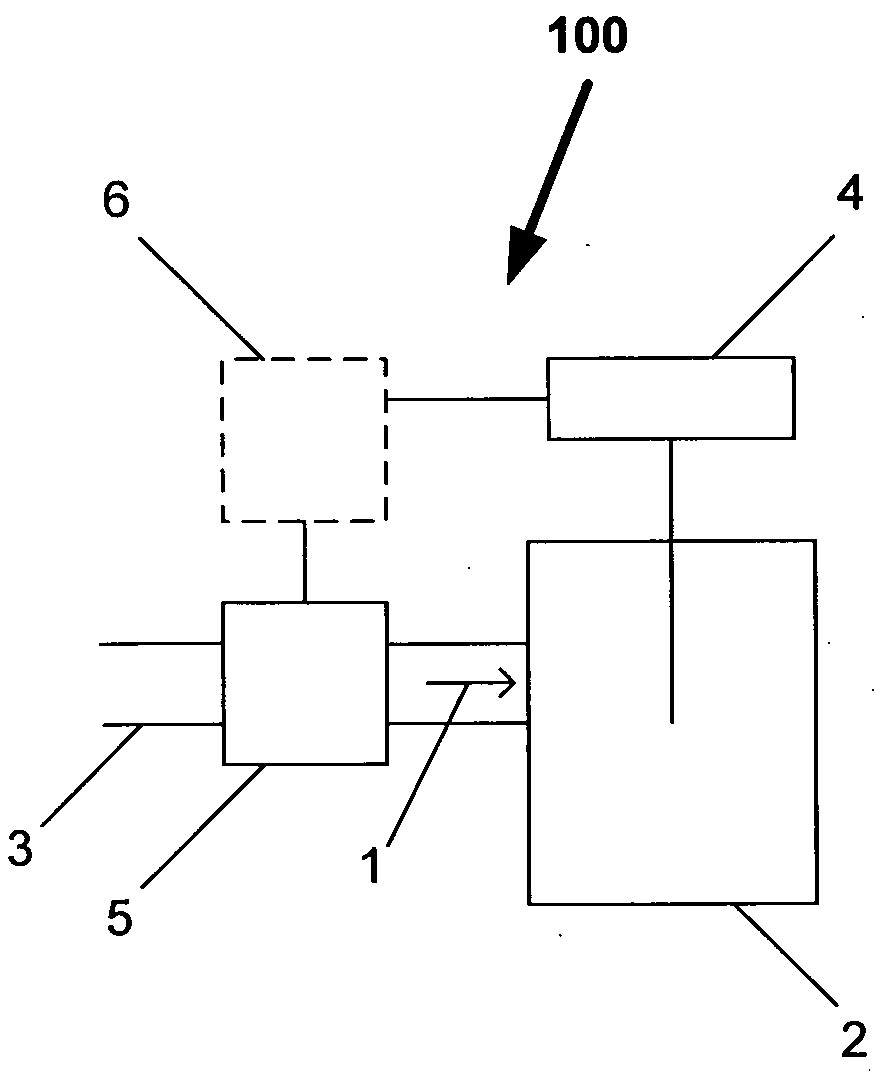

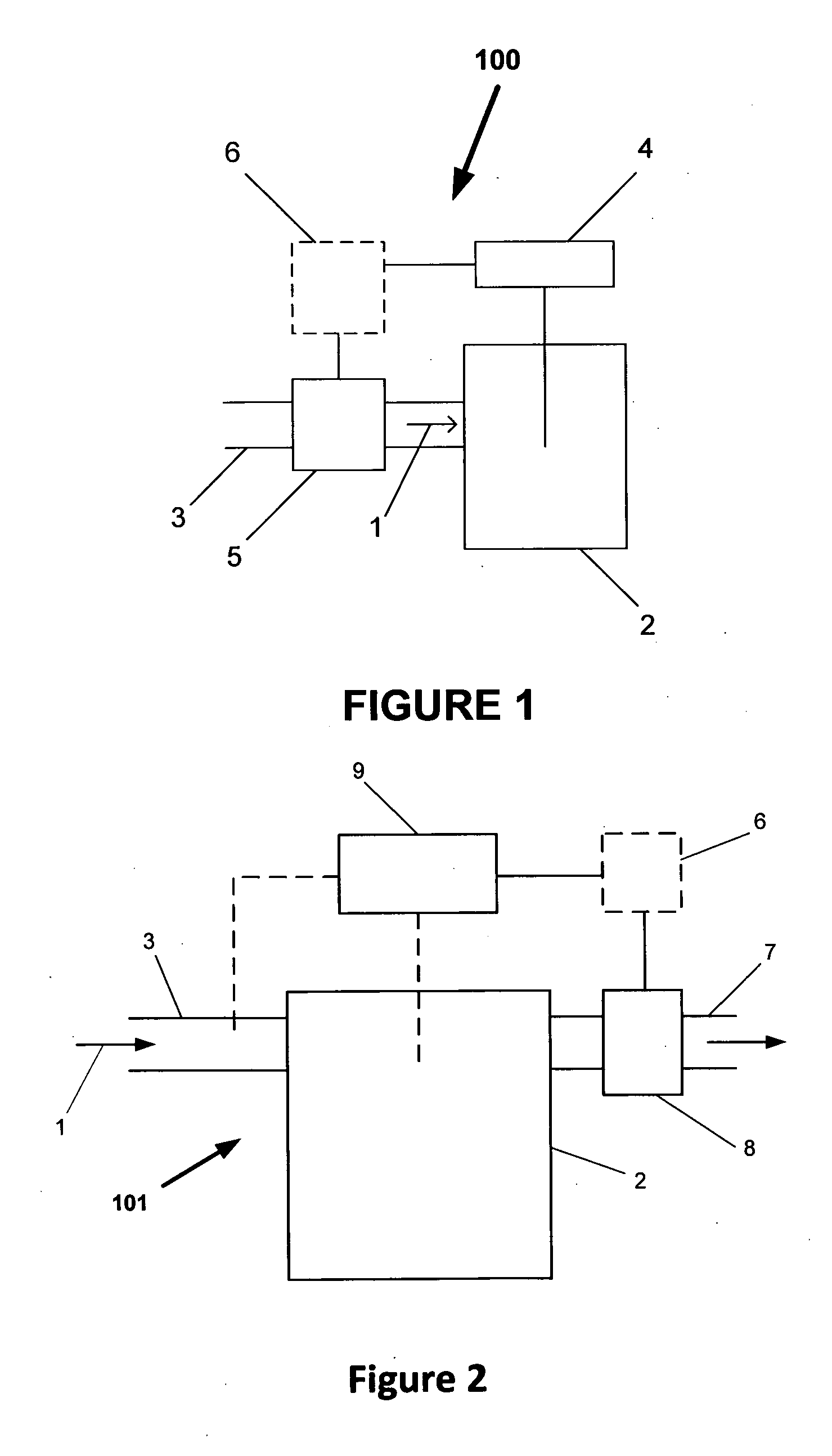

Method used

Image

Examples

example 1

[0210]Approximately 1400 mL of solution A was transferred into a 1.5 L fermenter and sparged with nitrogen. Resazurin (1.5 mL of a 2 g / L solution) and H3PO4 (85% solution, 2 mL) was added and the pH adjusted to 5.3 using concentrated NH4OH (aq). Chromium(II)chloride was added until the ORP of the solution decreased to approximately −150 mV. Sodium polysulfide (4.2 mL of a 4.3M solution) was added, the solution sparged with N2, then solution D (1.5 mL), solution B (15 mL) and Na2WO3 (1.5 mL of a 0.01M solution) were added. Solution F (15 mL) was added, the pH was adjusted to 5.5 and the solution sparged with N2 before switching to CO containing gas (50% CO; 50% N2) at 40 mL / min. The reactor was then inoculated with 150 ml of a Clostridium autoethanogenum culture. The bioreactor was maintained at 37° C. and stirred at 300 rpm. During the growth phase, the agitation was increased to stepwise to 800 rpm.

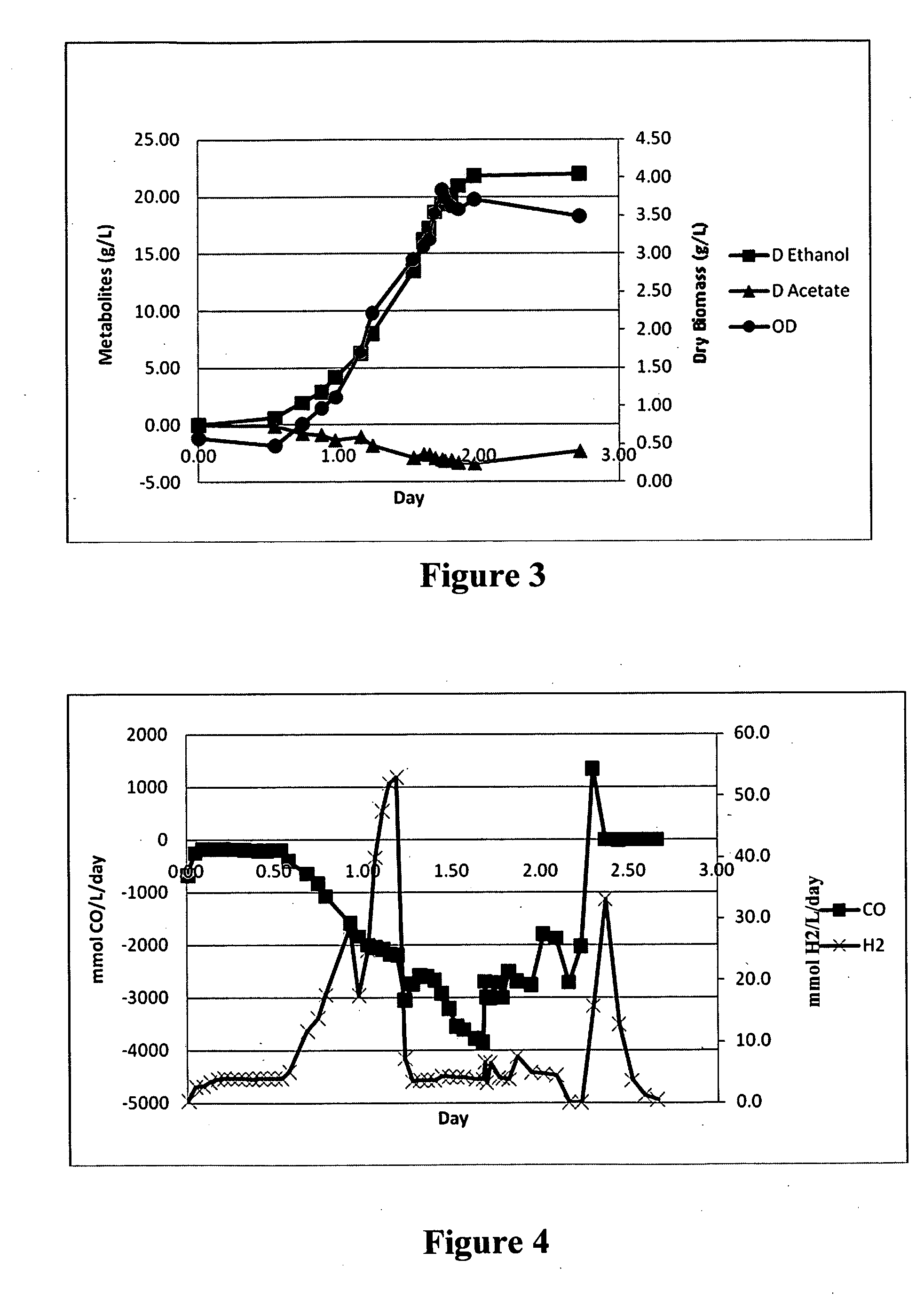

[0211]Metabolite and microbial growth can be seen in FIG. 3. Durin...

example 2

[0213]Media was prepared at pH 5.5 as follows. All ingredients in solution E with the exception of Cysteine-HCl were mixed in 400 ml distilled water. This solution was made anaerobic by heating to boiling and allowing it to cool to room temperature under a constant flow of 95% CO, 5% CO2 gas. Once cool, the Cysteine-HCl was added and the pH of the solution adjusted to 5.5 before making the volume up to 1000 ml; anaerobicity was maintained throughout the experiments.

[0214]A 1 L bioreactor was charged with 400 ml Solution E media, prepared as described above under a constant flow of N2. The gas was switched to CO containing gas (50% CO; 50% N2) at atmospheric pressure prior to inoculation with 400 ml of a Clostridium autoethanogenum culture. The bioreactor was maintained at 37° C. stirred at 400 rpm at the start of the culture. During the growth phase, the agitation was increased to 400 rpm. The pH was maintained at 5.5 before allowing it to drop to pH 5.3. Following the initial growt...

example 4

[0220]Approximately 1400 mL of solution A was transferred into a 1.5 L fermenter and sparged with nitrogen. Resazurin (1.5 mL of a 2 g / L solution) and H3PO4 (85% solution, 2 mL) was added and the pH adjusted to 5.3 using concentrated NH4OH(aq). Chromium(II)chloride was added until the ORP of the solution decreased to approximately −150 mV. Sodium polysulfide (4.2 mL of a 4.3M solution) was added, the solution sparged with N2, then solution B (15 mL), solution G (1.5 mL) and Na2WO3 (1.5 mL of a 0.01M solution) were added. Solution F (15 mL) was added, the pH was adjusted to 5.5 and the solution sparged with N2 before switching to CO containing gas (50% CO; 50% N2) at 40 mL / min. The reactor was then inoculated with 150 ml of a Clostridium autoethanogenum culture. The bioreactor was maintained at 37° C. and stirred at 300 rpm. During the growth phase, the agitation was increased to stepwise to 800 rpm.

[0221]Metabolite and microbial growth can be seen in FIG. 9. During the growth phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentrations | aaaaa | aaaaa |

| concentrations | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com