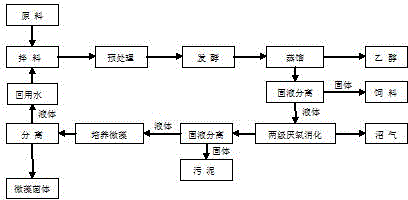

Method for culturing microalgae by using alcohol wastewater and fermentation exhaust

An alcoholic wastewater and alcoholic fermentation technology, applied in the field of bioengineering, can solve the problems of consuming large amounts of energy and increasing the cost of alcohol production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Take 300L of two-stage anaerobic digestion alcohol wastewater from a factory (the total ammonia nitrogen content is 911.5mg / L, and the total phosphorus content is 88.3mg / L) and add it to the bioreactor, inoculate 5% microalgae cells, and wait 20 days for the microalgae cells to When the reproduction is vigorous, the total ammonia nitrogen and total phosphorus in the wastewater are determined to be 10.3mg / L and 0.35mg / L respectively, reaching the reuse standard. Filter and separate 3000g (dry weight) of the microalgae cell product, in which the bio-oil content is 40%. The purified reused water is directly added to the mixing process of alcoholic fermentation, and the alcohol concentration in the final fermentation liquid is equivalent to that of the control group (non-reused water).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com