Fuel ethanol production equipment and method

A technology for fuel ethanol and a production method, which is applied to biochemical equipment and methods, fuels, biofuels, etc., can solve problems such as high energy consumption and material consumption, water pollution, etc., and achieves increasing feed temperature, reducing steam consumption, and saving circulating cooling. water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

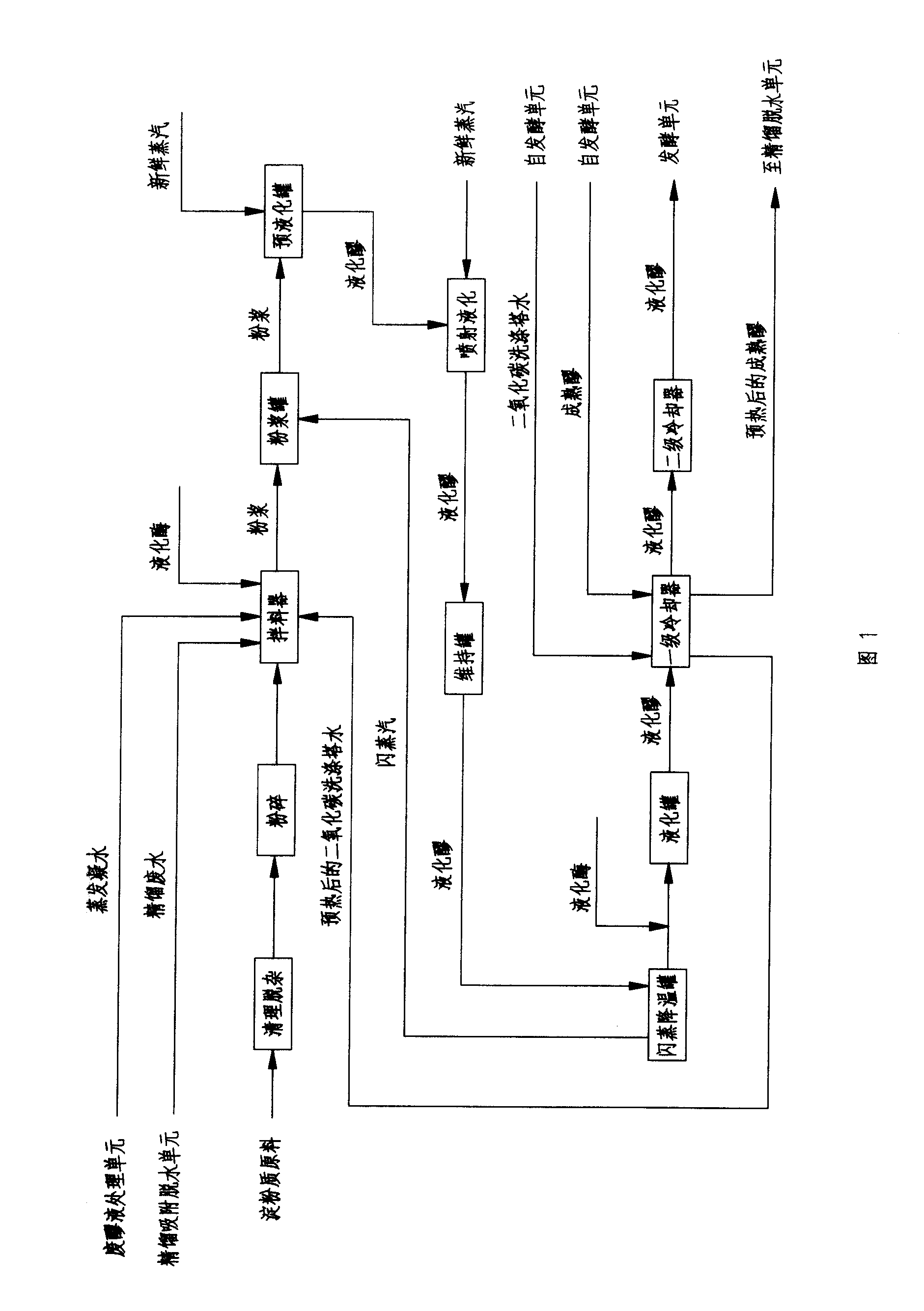

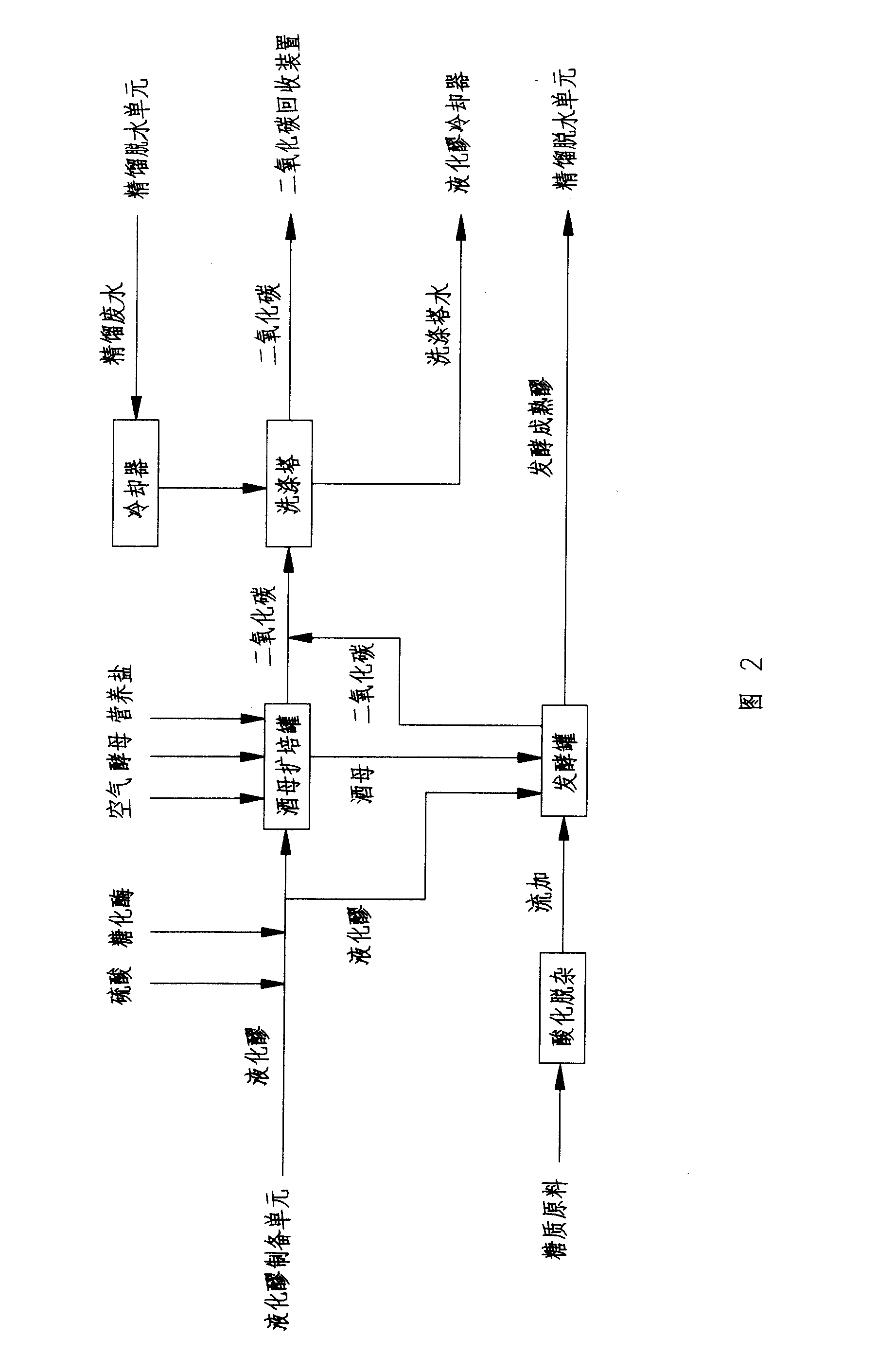

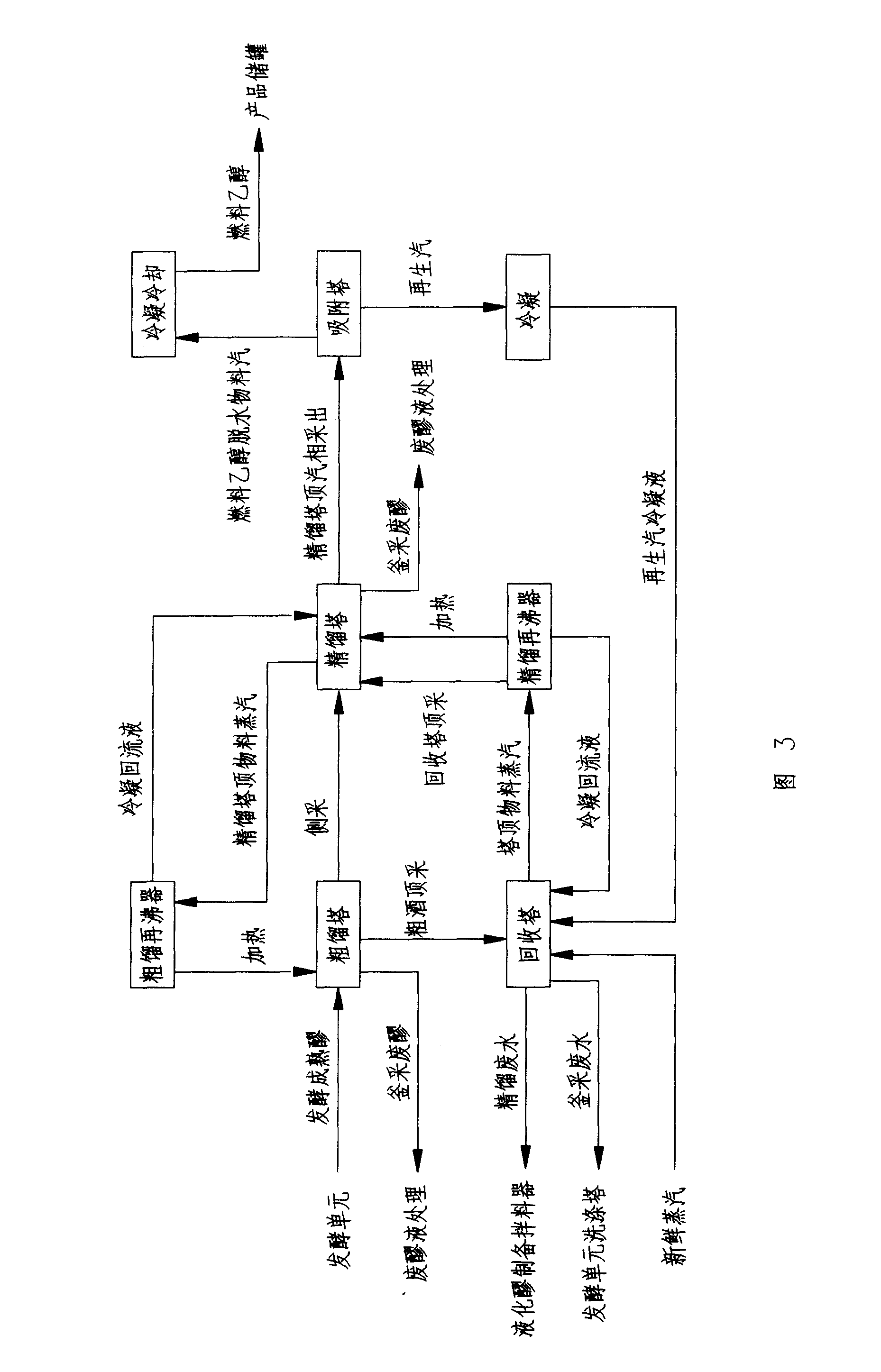

[0044] Using cassava as raw material, the production method shown in Figure 1, Figure 2, Figure 3 and Figure 4 is used to produce fuel ethanol.

[0045] The cassava raw material with a starch content of 68%, with a processing capacity of 7.5 tons per hour, is cleaned and decontaminated and then pulverized. The pulverized raw material is added with mixing water to make a slurry and sent to the slurry tank. The mixing water is from CO 2 The washing water from the washing tower, the waste water from the recovery tower bottom of the rectification dehydration unit, and the condensed water from the waste liquid treatment unit add up to 17.7 tons / hour. In the slurry tank, the steam generated by the flash cooling of the liquefied mash is preheated. The preheated slurry is sent to the pre-liquefaction tank, and auxiliary materials such as amylase are added quantitatively for pre-liquefaction operation, and the pre-liquefaction temperature is controlled by steam to 60°C.

[0046] After...

Embodiment 2

[0058] Using corn as raw material, the production process shown in Figure 1, Figure 2, Figure 3 and Figure 4 is used to produce fuel ethanol.

[0059] The corn raw material with a starch content of 63%, with a processing capacity of 9.3 tons per hour, is cleaned and decontaminated and then pulverized. The pulverized raw material is made into a slurry with mixing water and sent to the slurry tank. The mixing water is from CO 2 The washing water from the washing tower, the waste water from the recovery tower bottom of the rectification dehydration unit, and the condensed water from the waste liquid treatment unit add up to 27 tons / hour. In the slurry tank, the steam generated by the flash cooling of the liquefied mash is preheated. The preheated slurry is sent to the pre-liquefaction tank, and auxiliary materials such as amylase are added to carry out the pre-liquefaction operation, and the pre-liquefaction temperature is controlled by steam to be 65°C.

[0060] After the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com