Magnetic polydimethylsiloxane (PDMS) mask-based micro-pit array electrolytic machining system and method

A micro-pit array and mask technology, applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of PDMS disturbance, weak adhesion, difficult to achieve, etc., to achieve stable PDMS properties and improve processing stability. Domain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

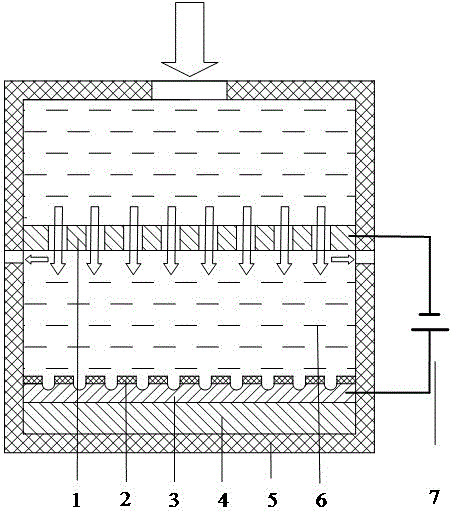

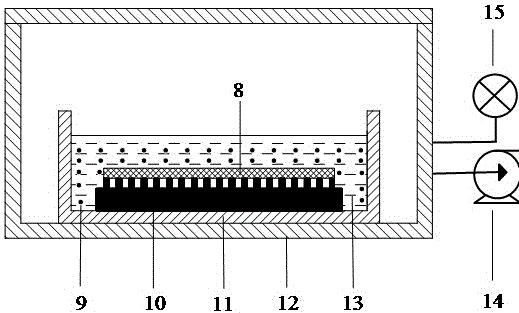

[0019] The present invention is illustrated below in conjunction with the accompanying drawings: a system and method for electrolytic machining of micro-pit arrays based on a magnetic PDMS mask, comprising the following steps:

[0020] a. Make the cathode tool 1 and the fixture 5. The cathode tool 1 has a uniform group seam structure, the diameter of the liquid inlet of the fixture is 20 mm, and two liquid outlets are arranged on the lower surface of the cathode tool, with a diameter of 1 mm;

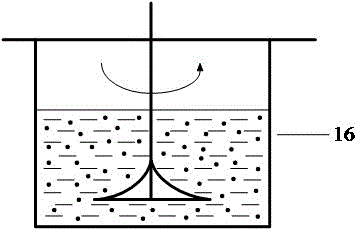

[0021] b. Make a magnetic PDMS mask 2 with an array of through holes, such as Figure 5 ;

[0022] c. Stick the magnetic PDMS mask 2 on the upper surface of the anode workpiece 3, the permanent magnet 4 is close to the lower surface of the anode workpiece, and use the clamp 5 to clamp the cathode tool 1 and the anode workpiece 3 together, wherein the cathode tool 1 and the magnetic PDMS mask The distance of mold 2 is 15mm;

[0023] d. The anode workpiece 3 and the cathode tool 4 are r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com