Aluminium wheel spinning mould ejector

A technology for ejectors and wheels, which is applied in the direction of pushing out equipment, etc., can solve the problems that the ejector of the lower die cannot return normally, produces aluminum chips, and scratches on the back cavity of the wheel spokes, and achieves the effect of improving the difficulty of returning to the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Technical scheme of the present invention is:

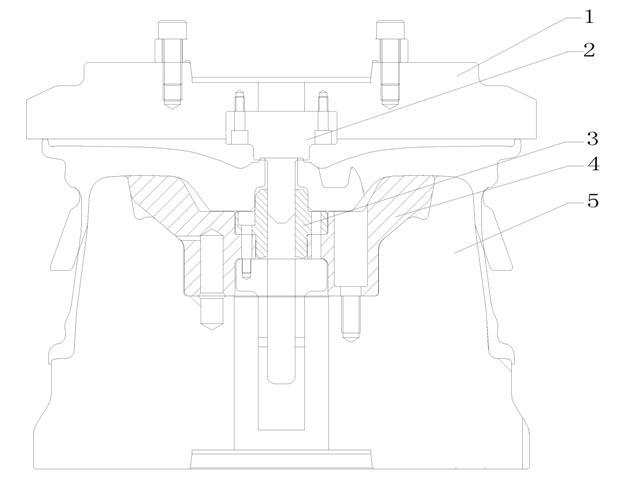

[0023] Change the opening position and angle of the 4 conical surfaces of the lower die ejector, change the middle part of the spokes of the prior art to the arc at the junction of the spokes and the rim, and change the angle from 50° to 45°.

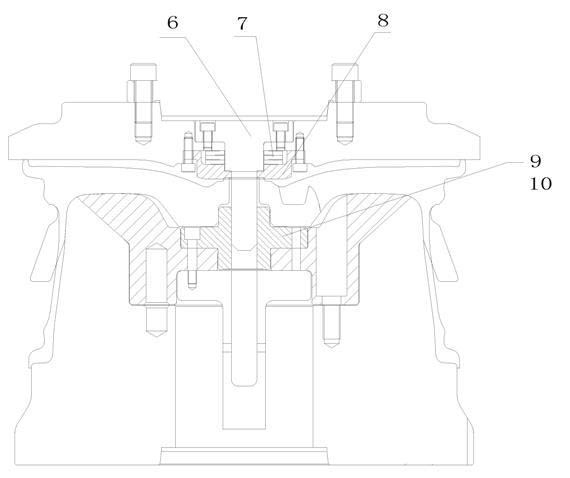

[0024] Mill the anti-rotation groove at the joint surface with the back cavity of the spoke, and change the connection position between the ejector of the lower die and the guide copper sleeve;

[0025] Decompose the upper mold ejector into new upper mold ejector 8 and guide column 6. The new upper die ejector 8 is connected with the upper die bolts; the guide column 6 is connected with the upper die bolts to play a guiding role.

[0026] There is disc spring 7 between new upper die ejector 8 and upper die 1.

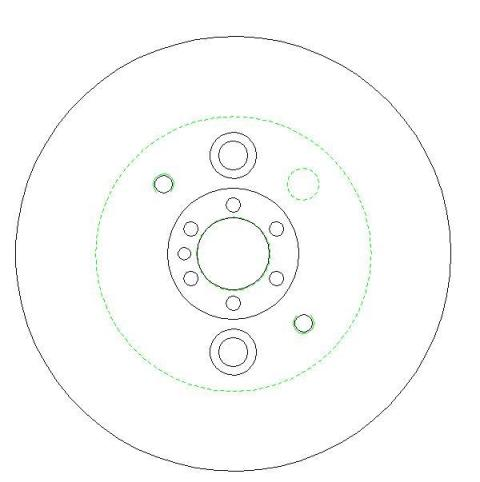

[0027] Described new lower die ejector 10 replaces lower die ejector 4, as figure 2 , Figure 4 shown. The new guide copper sleeve 9 replaces the guide copper sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com