Technique for producing spherical distributor

A manufacturing process and distributor technology, which is applied in the field of spherical distributor manufacturing technology, can solve the problems that the drill bit cannot be positioned, the groove of the pipe joint and the spherical surface are difficult to match, etc., and achieve the effect of solving localization and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

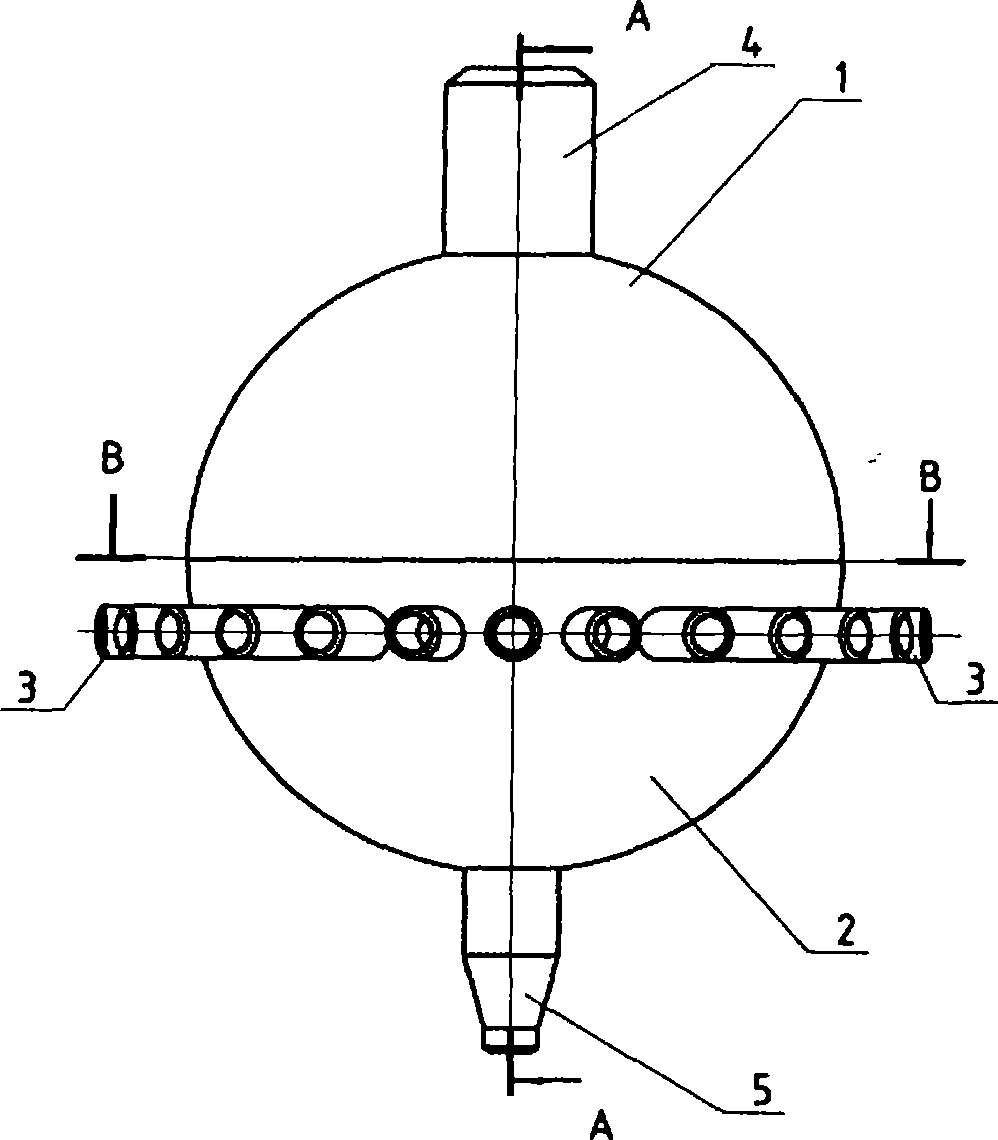

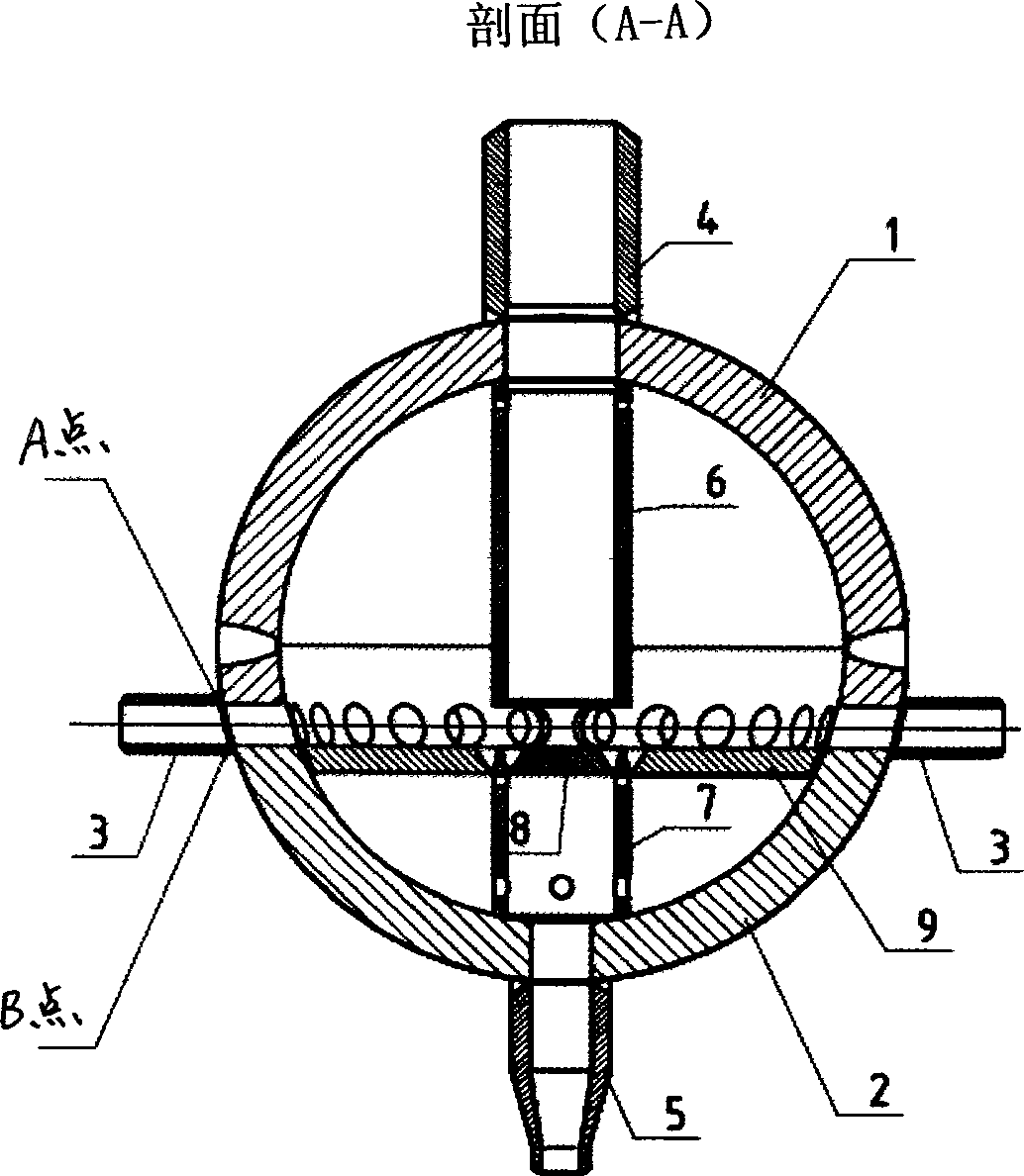

[0024] Such as figure 1 , 2 , Shown in 3, is a schematic diagram of the spherical distributor structure, the present embodiment further illustrates the present invention by manufacturing 16 spherical distributors in Baosteel 4# unit 350MW tower gas and oil fired boilers.

[0025] A spherical distributor manufacturing process is:

[0026] The first step. Install the pipe joint 4 and the inner long pipe 6 inside and outside the top of the upper half head 1 with a diameter of 508mm, so that the pipe joint 4 and the inner long pipe 6 are located on the diameter of the upper half head 1, and the pipe joint 4 has the same diameter as the inner long pipe 6, the diameter is 100mm, the length of the pipe joint 4 is 148mm, and the length of the inner long pipe 6 is 248mm;

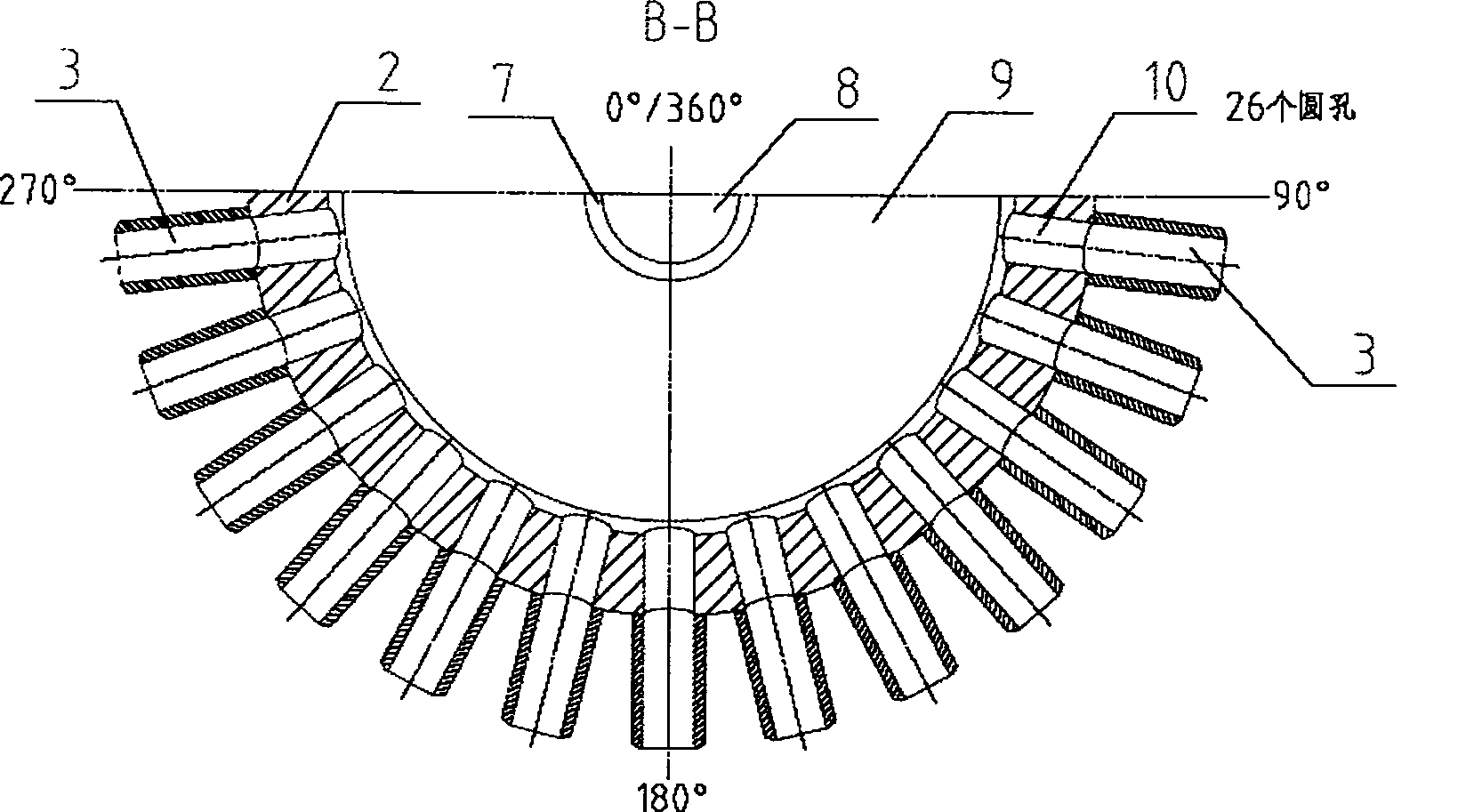

[0027] Step 2. At the ring seam of the lower half of the head with a diameter of 508mm, 60mm away from the centerline of the pipe hole of the miter pipe 3, evenly draw 26 positions that need to be drilled, and at e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com