Computer electric source

A technology of computer power supply and power supply circuit, applied in the field of power supply, can solve the problems of low heat dissipation efficiency of computer power supply, inability to get rid of traditional methods, low heat transfer efficiency, etc., and achieve the effect of favorable heat dissipation, cost reduction and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

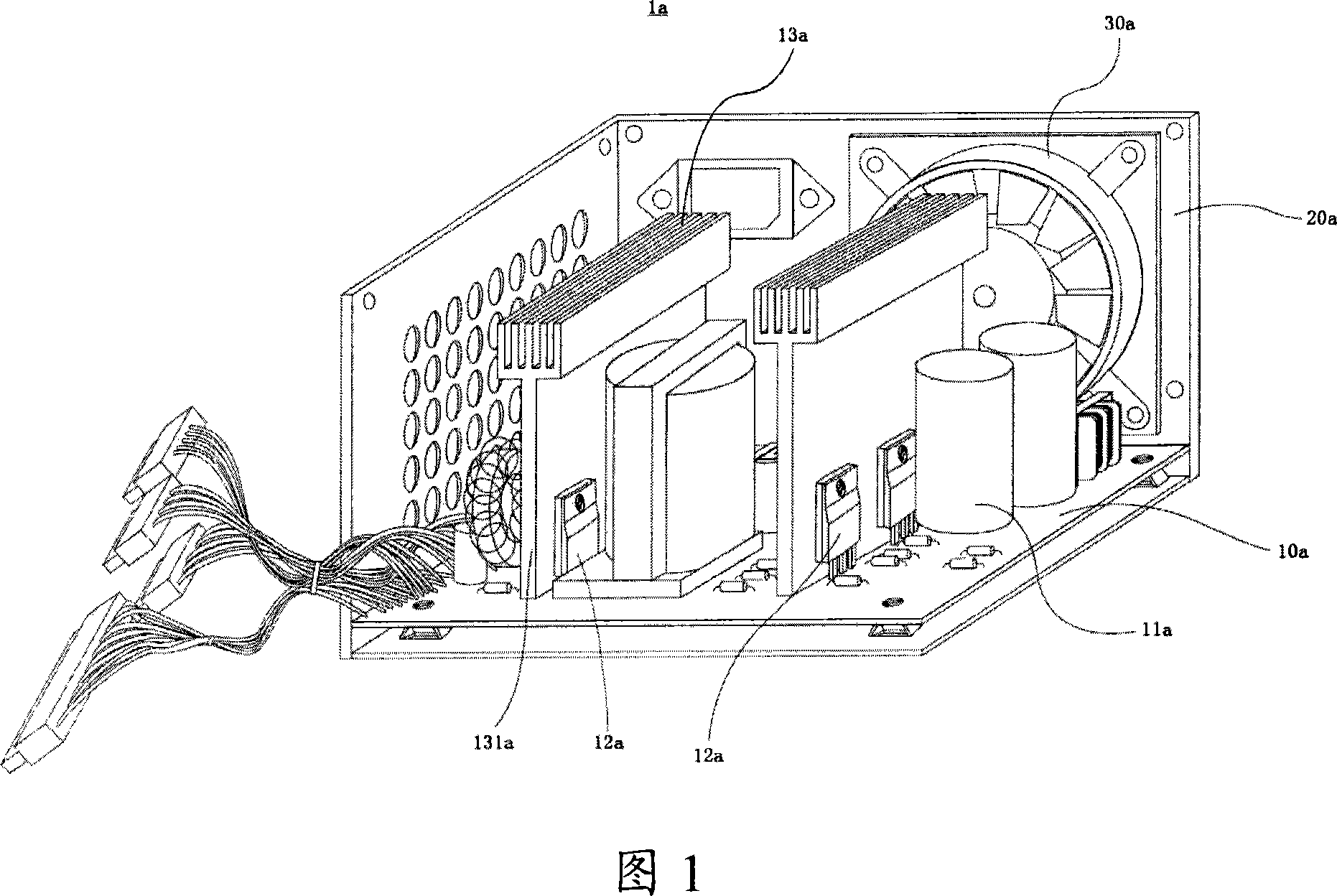

[0041] Fig. 4 and Fig. 6 are three-dimensional exploded view and combined schematic diagram respectively of this embodiment, mainly include parts such as sub-circuit board 10, main circuit board 20, upper case 30 and lower case 40, and upper case 30 and lower case The casing 40 constitutes an example of a power supply casing in the embodiment of the present invention, and the outer wall of the upper casing 30 includes cooling fins. in:

[0042] The electrical connector connecting the sub-circuit board 10 and the main circuit board 20 is made of a plug and a socket with flexible wire bundles, including at least two electrical connectors, one (plug 14, socket 22) is connected with the switching element 11 and the switching transformer 13 primary relevant circuits, one (plug 15, socket 23) is connected with rectifying element 12 and the secondary relevant circuit of switching transformer 13. The specification of the electrical connector depends on the power of the power supply. ...

no. 2 example

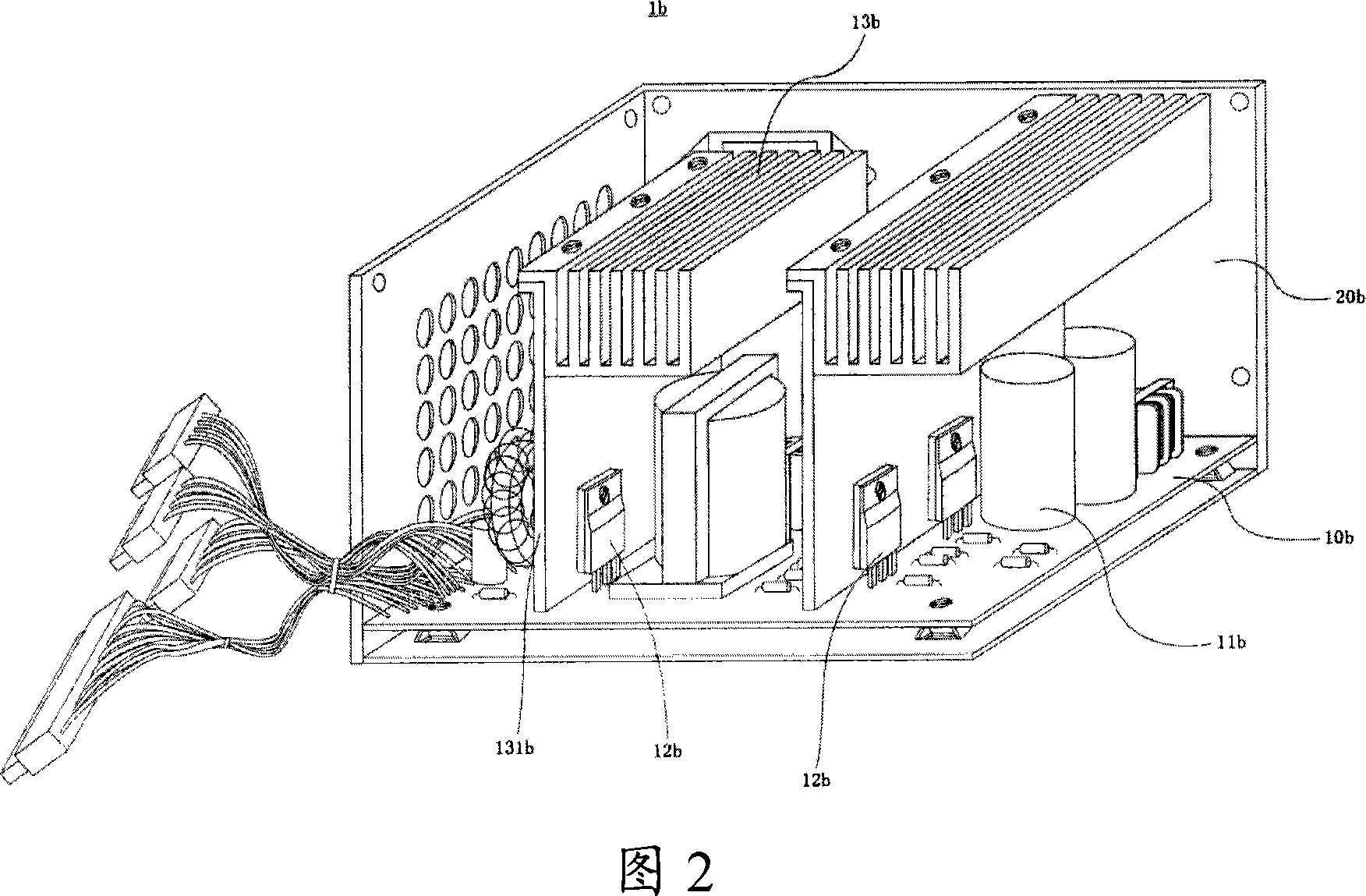

[0052] This embodiment is an embodiment of the computer power supply under the general power demand. In this case, the heat dissipated by the inner wall of the upper casing is relatively small, so even if a sub-circuit board with a relatively small size is used, it is the embodiment of this embodiment. In the sub-circuit board 50, the internal temperature of the power supply can also be maintained at a normal level.

[0053] Because the difference between the second embodiment and the first embodiment only lies in: the shape and size of the sub-circuit board are different; The installation location is different. Therefore, only the differences from the first embodiment will be introduced below, and the rest can refer to the relevant content in the first embodiment.

[0054] Fig. 5 and Fig. 6 are three-dimensional exploded view and combined schematic diagram respectively of this embodiment, mainly include components such as sub-circuit board 50, main circuit board 20, upper ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com