Preparation process of high-weldability flaky silver graphite contactor of parallel structure

A preparation process, silver-graphite technology, applied in the direction of contacts, electrical components, electrical switches, etc., can solve problems such as affecting the solderability of contacts in mass production of products, limiting the range of final product size, and the thickness and size of contacts cannot be too thin, etc. , to improve the processing performance and weldability, reduce the sintering process, and avoid poor workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Calculate the required amount of silver powder and graphite powder according to the material ratio for preparing 10kg AgC (3), weigh 9.7kg silver powder and 0.3kg silver graphite powder, and mix the powder on a double cone mixer at a speed of 25r / min. Time 2h, obtain mixed powder;

[0046] 2) the resulting mixed powder is placed on an isostatic pressing device for molding, and the molding pressure is 100MPa to obtain a silver graphite billet;

[0047] 3) The gained silver-graphite billet is placed in the decarburization furnace, feeds compressed air into the decarburization furnace, the air flow rate is 5L / min, the temperature is raised to 650° C., and the decarburization is carried out for 6 hours to obtain the decarburized silver-graphite billet;

[0048] 4) The obtained decarburized silver-graphite ingot is placed in a sintering furnace, and sintered under the protection of hydrogen at a sintering temperature of 800° C. for 6 hours to obtain a sintered silver-grap...

Embodiment 2

[0061] Repeat Example 1, the difference is:

[0062] In step 2), the isostatic pressing pressure is 150MPa;

[0063] In step 3), the flow of compressed air into the decarburization furnace is 10L / min, the decarburization temperature is 800°C, and the time is 2h;

[0064] In step 4), the sintering temperature is 900°C and the time is 3h;

[0065] In step 5), the extrusion temperature is 750° C., and the extrusion ratio is 80.

Embodiment 3

[0067] Repeat Example 1, the difference is:

[0068] In step 2), the isostatic pressing pressure is 120MPa;

[0069] In step 3), the flow rate of compressed air into the decarburization furnace is 8L / min, the decarburization temperature is 750°C, and the time is 3h;

[0070] In step 4), the sintering temperature is 850°C and the time is 4h;

[0071] In step 5), the extrusion temperature is 800° C., and the extrusion ratio is 200.

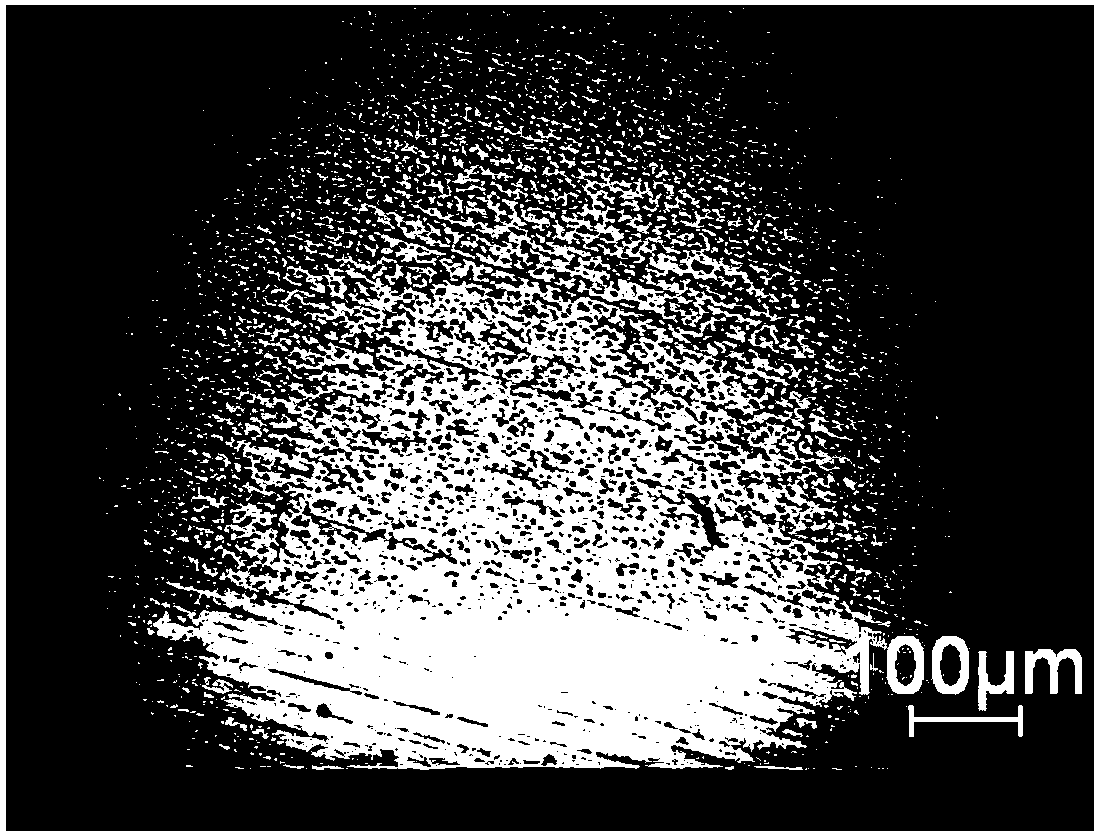

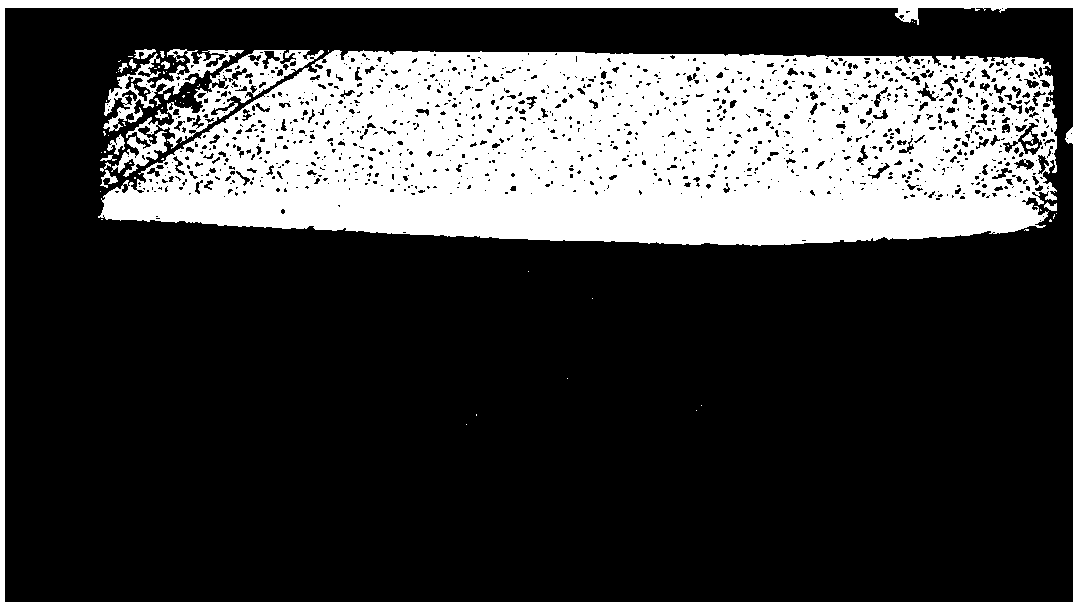

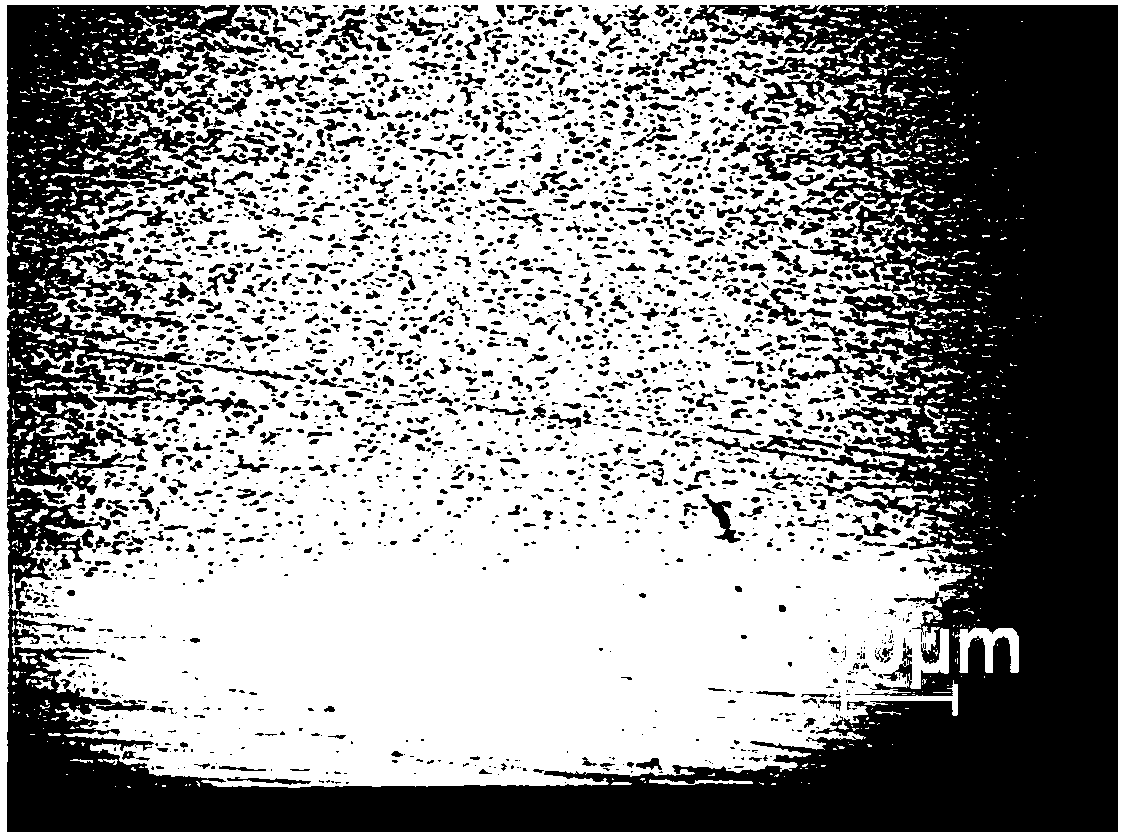

[0072] Metallographic structure analysis is carried out to the contact material that above-mentioned embodiment 1-2 and comparative example 1 make, respectively as follows figure 1 , 3 Shown in and 5; And metallographic structure analysis is carried out after carrying out materialless resistance welding to the contact that embodiment 1-2 and comparative example 1 make, respectively as figure 2 , 4 and 6.

[0073] Depend on Figure 1-6 It can be seen that the metallographic structure of the contact prepared by the process of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com