Analog simulation system for steel rolling skill training and assessment

A technology of simulation and skills, applied in the field of simulation system, can solve problems such as single teaching method, boring teaching content, vague structure and operation of steel rolling equipment, etc., and achieve the effect of stimulating creative thinking, intuitive theory, and cultivating innovation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

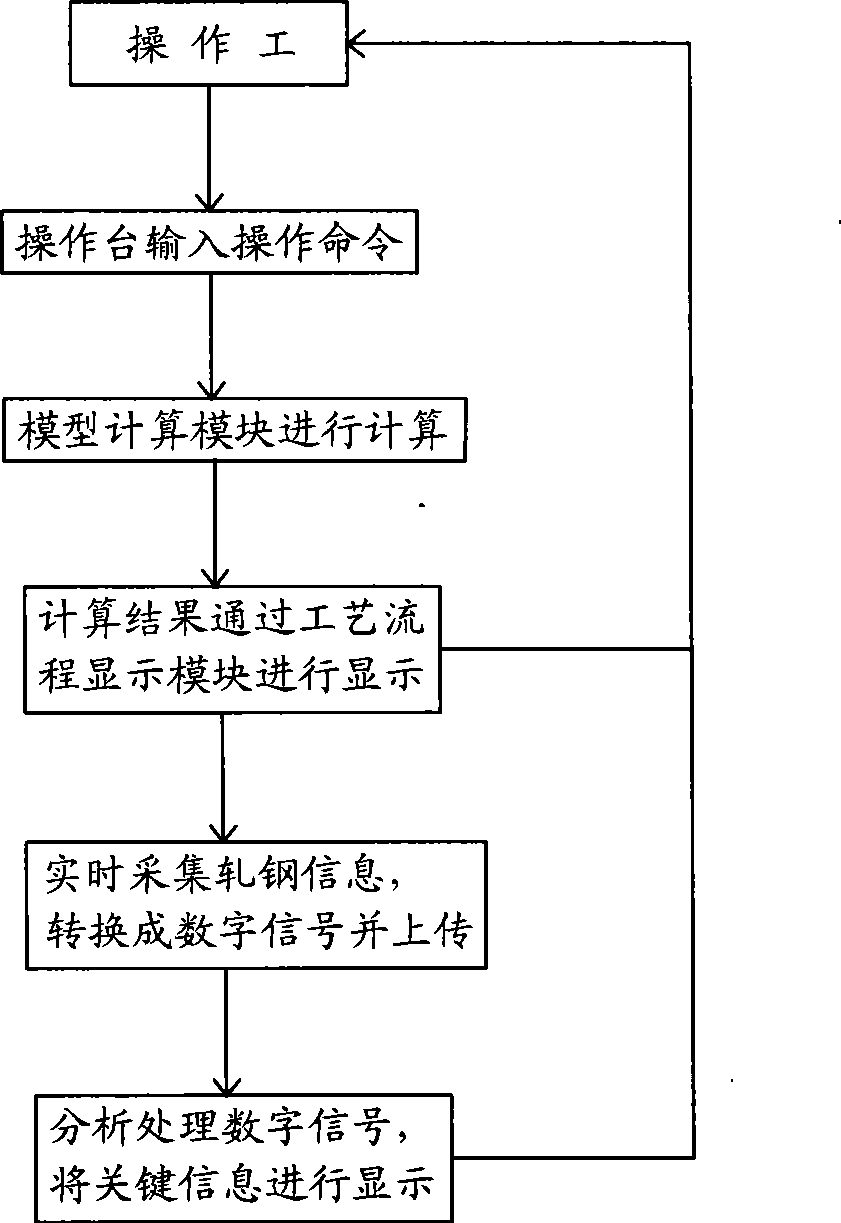

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

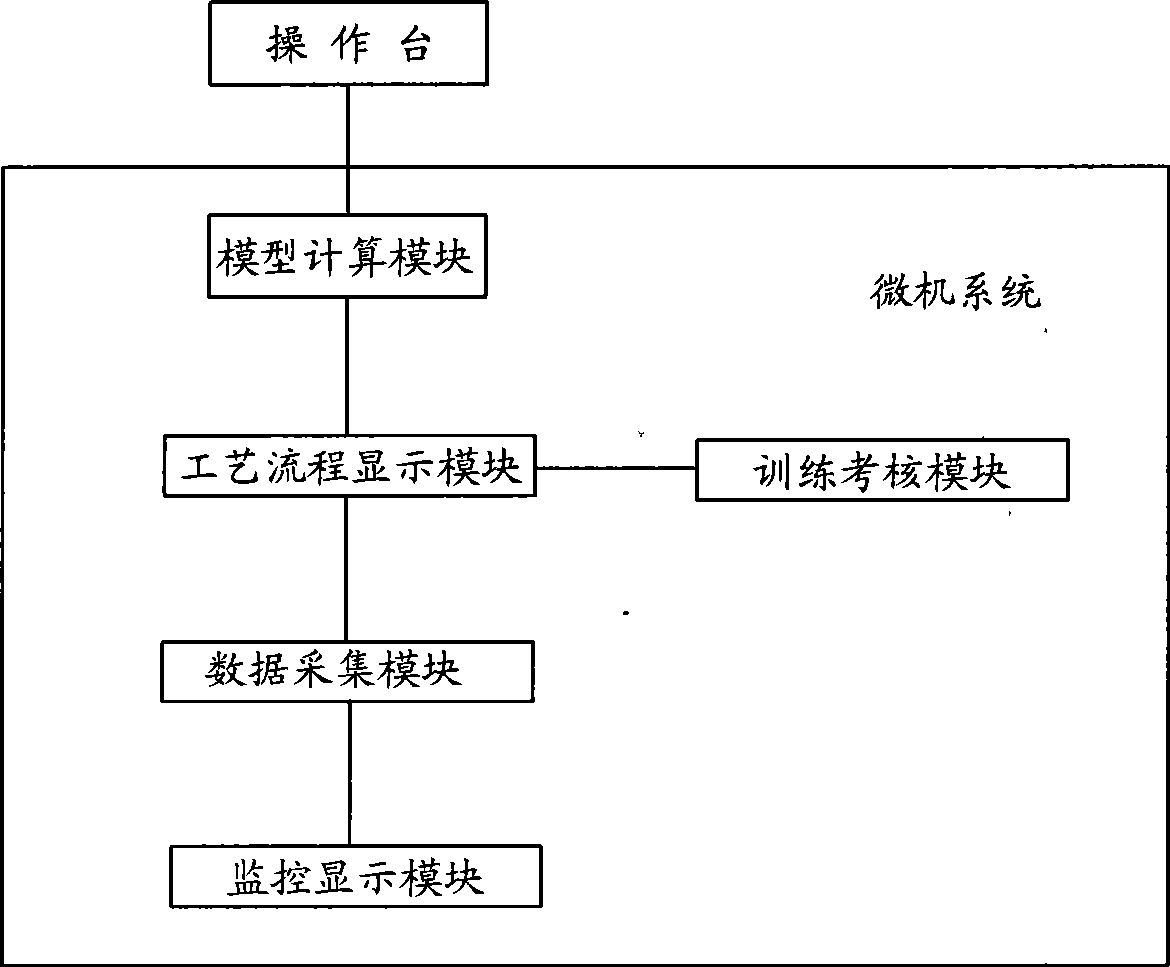

[0019] see figure 1 , the present invention includes a console and a microcomputer system, the microcomputer system is provided with a steel rolling simulation simulation device, and the steel rolling simulation simulation device includes a model calculation module, a process flow display module, a data acquisition module, a monitoring display module, and a training assessment module.

[0020] The model calculation module receives the control signal input from the console, and generates the corresponding virtual production process data after calculation. The model calculation module is an important part of the system, which is responsible for data exchange with other modules and provides real-time display data for the process flow display module. This module involves the following basic models: the motor model of the main rolling mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com