Configurable production line management and control system

A control system and production line technology, applied in manufacturing computing systems, technical management, instruments, etc., can solve the problems of inaccurate definition of classification standards, flexibility of control systems, poor adaptability, and insufficient granularity of control, etc., to reduce access to databases Times and time, avoiding code-level adaptive maintenance, and improving the effect of high cohesion and low coupling capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

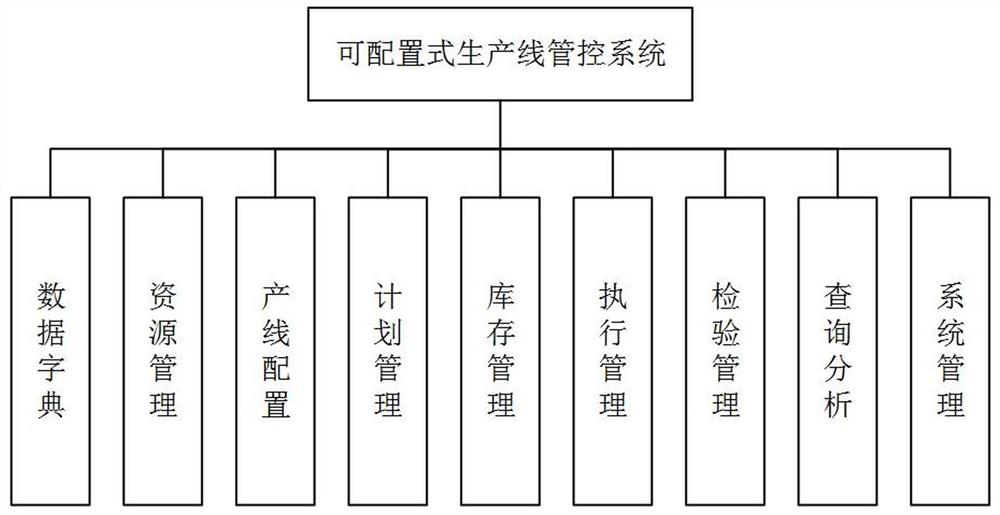

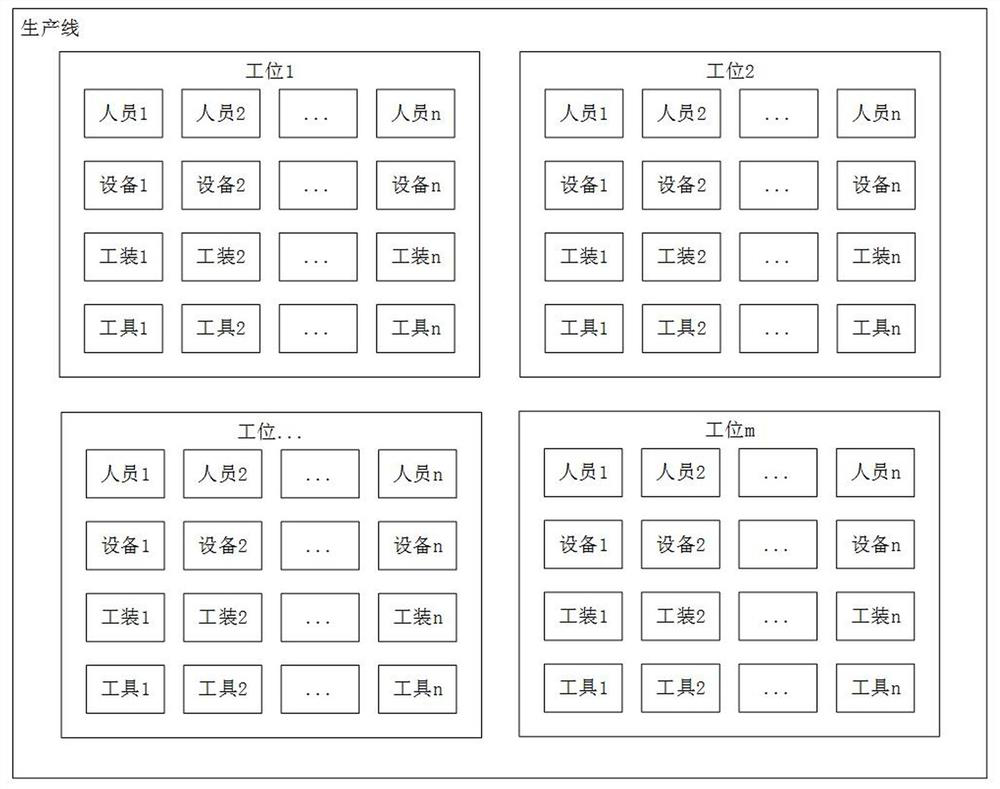

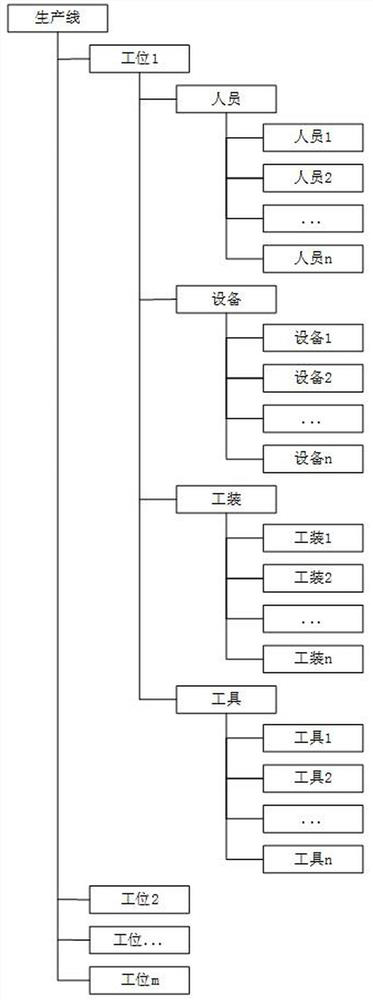

[0030] As the basic implementation of the present invention, the present invention includes a configurable production line management and control system, including a data dictionary module, a resource management module, a production line configuration module, a plan management module, an inventory management module, an execution management module, an inspection management module, a query Analysis module and system management module. The production line includes a series of workstations, where the workstation is the most basic production unit, on which personnel, equipment, tooling, tools and raw materials are arranged for production. The data dictionary module is used to describe and define data information, and realize the normalization and standardization of various terms in the system. The resource management module is mainly to manage resource ledgers such as workstations, personnel, equipment, tooling, and tools in the production line, so as to realize resource status mai...

Embodiment 2

[0032] As a preferred embodiment of the present invention, the present invention includes a configurable production line management and control system, including a data dictionary module, a resource management module, a production line configuration module, a plan management module, an inventory management module, an execution management module, and an inspection management module , query analysis module and system management module.

[0033]The production line configuration module is used to realize the definition and configuration of the virtual production line of the system, specifically refers to: customally construct the virtual production line according to the components of the physical production line, realize the one-to-one mapping relationship between the physical production line and the virtual production line, and then complete The definition and configuration of the virtual production line provides data support for other functional modules. The physical production ...

Embodiment 3

[0035] As another preferred embodiment of the present invention, the present invention includes a configurable production line management and control system, including a data dictionary module, a resource management module, a production line configuration module, a plan management module, an inventory management module, an execution management module, and an inspection management module. module, query analysis module and system management module.

[0036] The inventory management module includes a timer and an alarm, the timer is used to control the time of each process, and the process includes an on-demand precise delivery process and a resource matching process on time; the alarm is used for overdue alarm and low inventory alarm .

[0037] The on-demand precise distribution process specifically refers to: the inventory management module delivers materials to the line-side warehouse of the production line on time within the scheduled date according to the issued production l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com