Filling production line control system based on virtual-reality technology and implementation method of filling production line control system

A virtual reality technology and control system technology, applied in the field of filling production line control system based on virtual reality technology, can solve the problems of long debugging process, time error, and device not moving in place, etc., to achieve fast and stable filling process, Broad market prospects, avoid time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

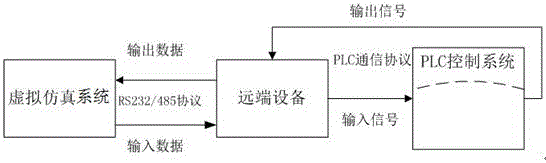

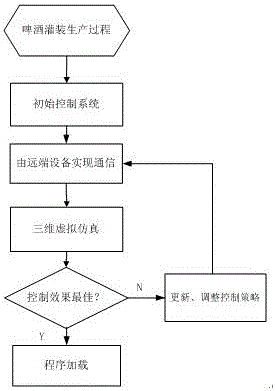

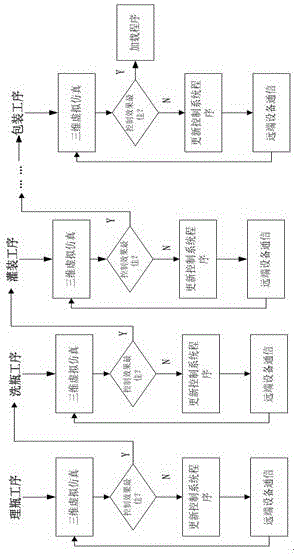

[0020] see Figure 1-3 , a filling production line control system based on virtual reality technology, including a virtual simulation system, a remote device, and a PLC control system, the virtual simulation system is bidirectionally connected to the remote device, and the remote device is bidirectionally connected to the PLC control system .

[0021] As mentioned above, the virtual simulation system includes a PC upper computer.

[0022] As mentioned above, the virtual simulation system creates a virtual simulation environment through 3DMax and Unity 3D, debugs and demonstrates in the virtual simulation environment, and synchronizes the results to the PLC control system.

[0023] As mentioned above, the PLC control system includes control buttons, operating handles and indicator lights.

[0024] As mentioned above, the PLC control system connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com