Digital twin system of an intelligent production line

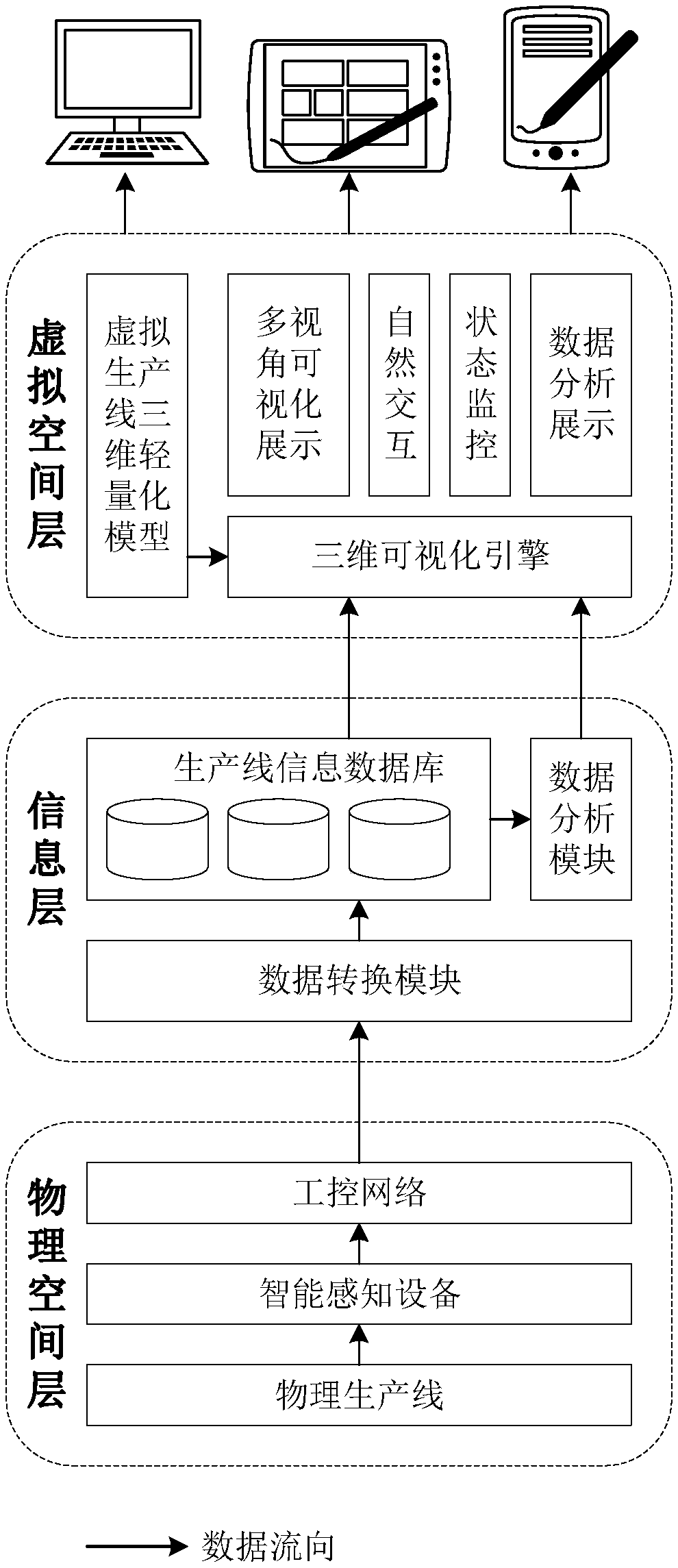

A production line and twinning technology, applied in the direction of manufacturing computing system, general control system, control/regulation system, etc., can solve the problems of no virtual 3D model, no support for remote, no way to provide natural interaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

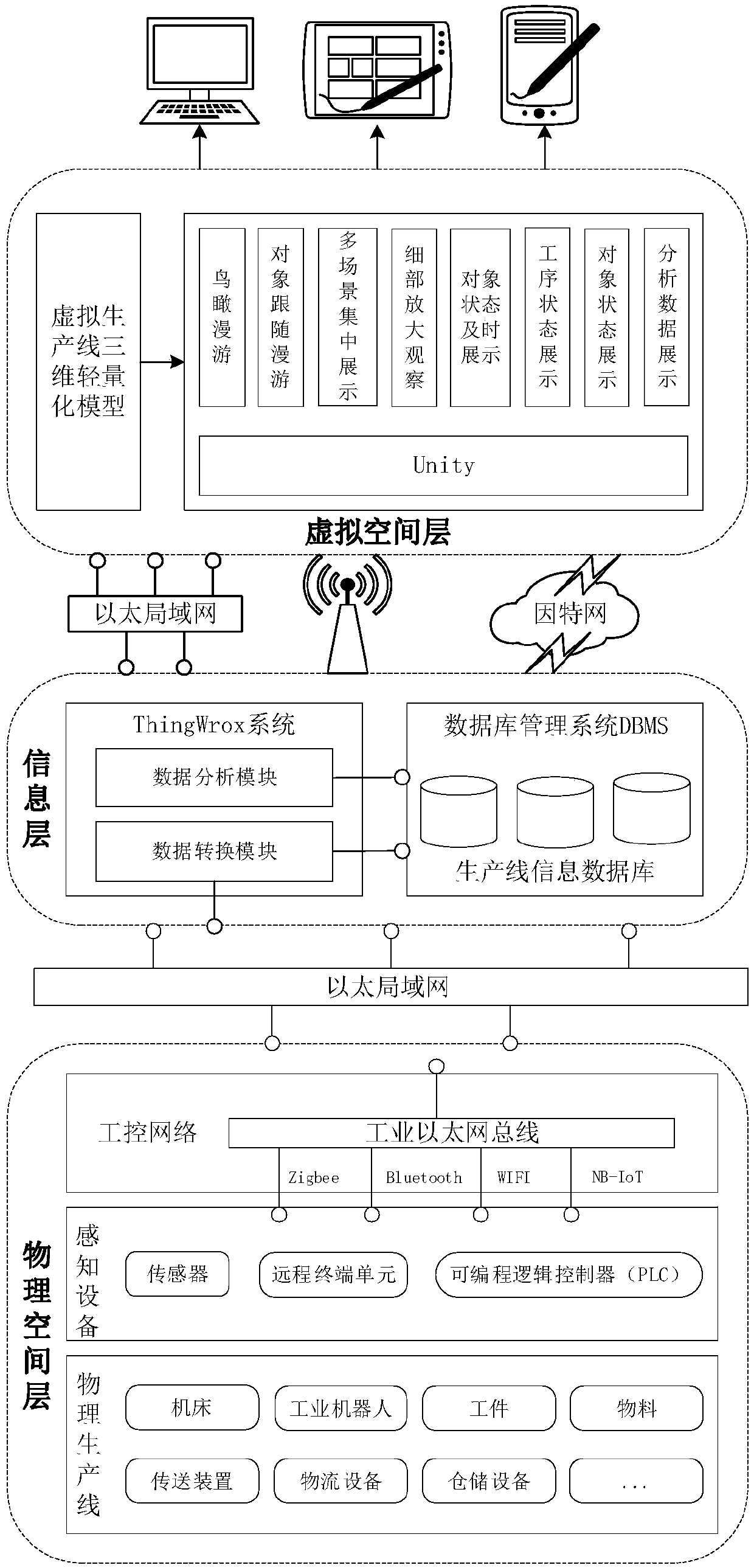

[0026] (1) Physical space layer implementation

[0027] Such as figure 2 As shown, the programmable logic controller PLC, sensors, remote terminal units and other intelligent sensing devices in the physical space layer are arranged on or connected to the corresponding units of the physical production line, so as to obtain information about machine tools, industrial robots, workpieces, and materials in the physical production line. , transmission device, logistics equipment, storage equipment position, pose, speed, status and other information.

[0028] Each intelligent sensing device is interconnected through the industrial Ethernet bus, supports Zigbee, Bluetooth, LAN, WIFI, NB-IoT and other transmission protocols, and is connected to the Ethernet local area network through the industrial Ethernet bus, so that the information layer can read the sensing data accordingly.

[0029] (2) Information layer implementation

[0030] Such as figure 2 As shown, the information laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com