Plastic recycling process and plastic recycling system

A technology of plastic recycling and cleaning system, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., to achieve the effect of high recycling rate, rigorous process and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

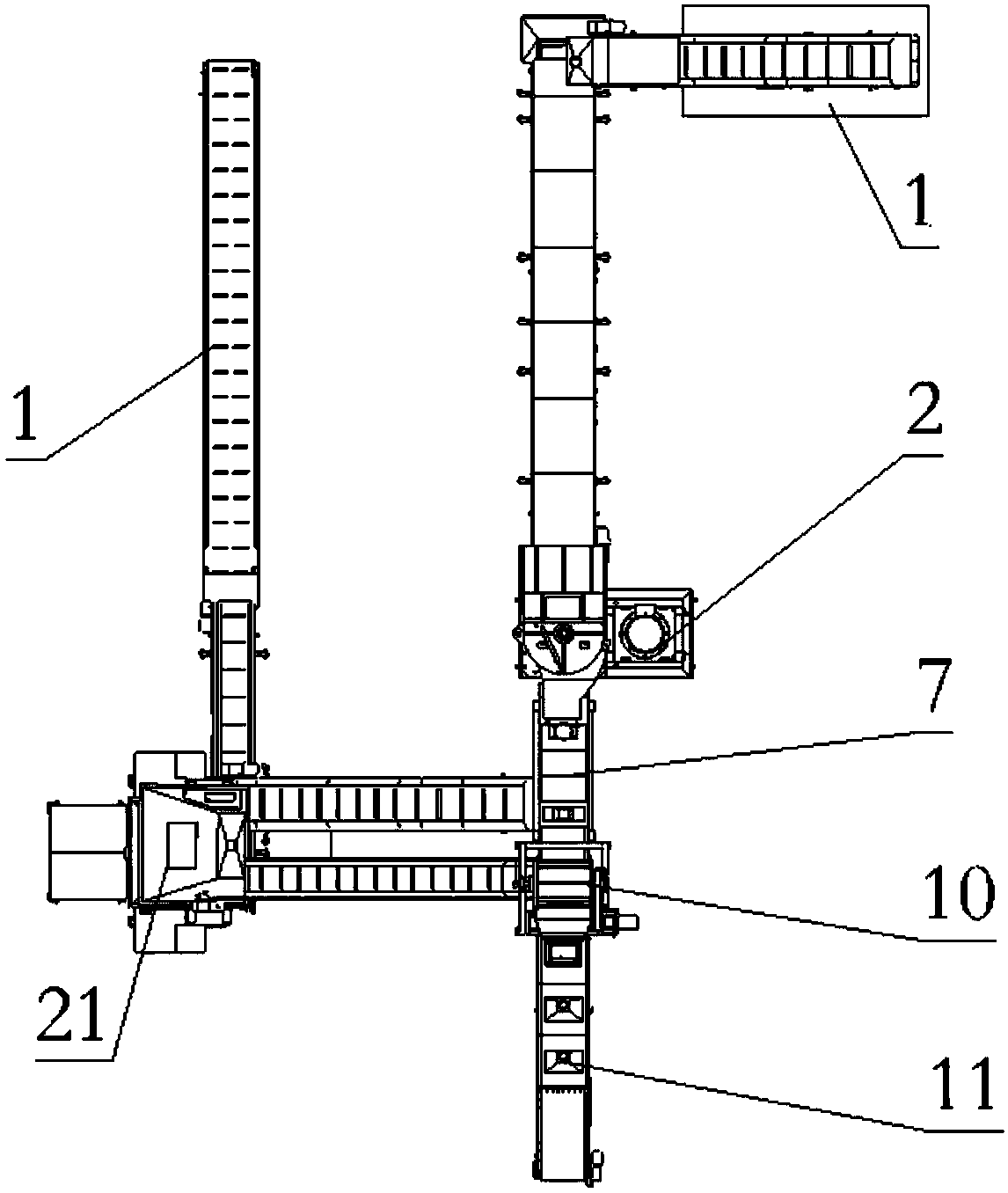

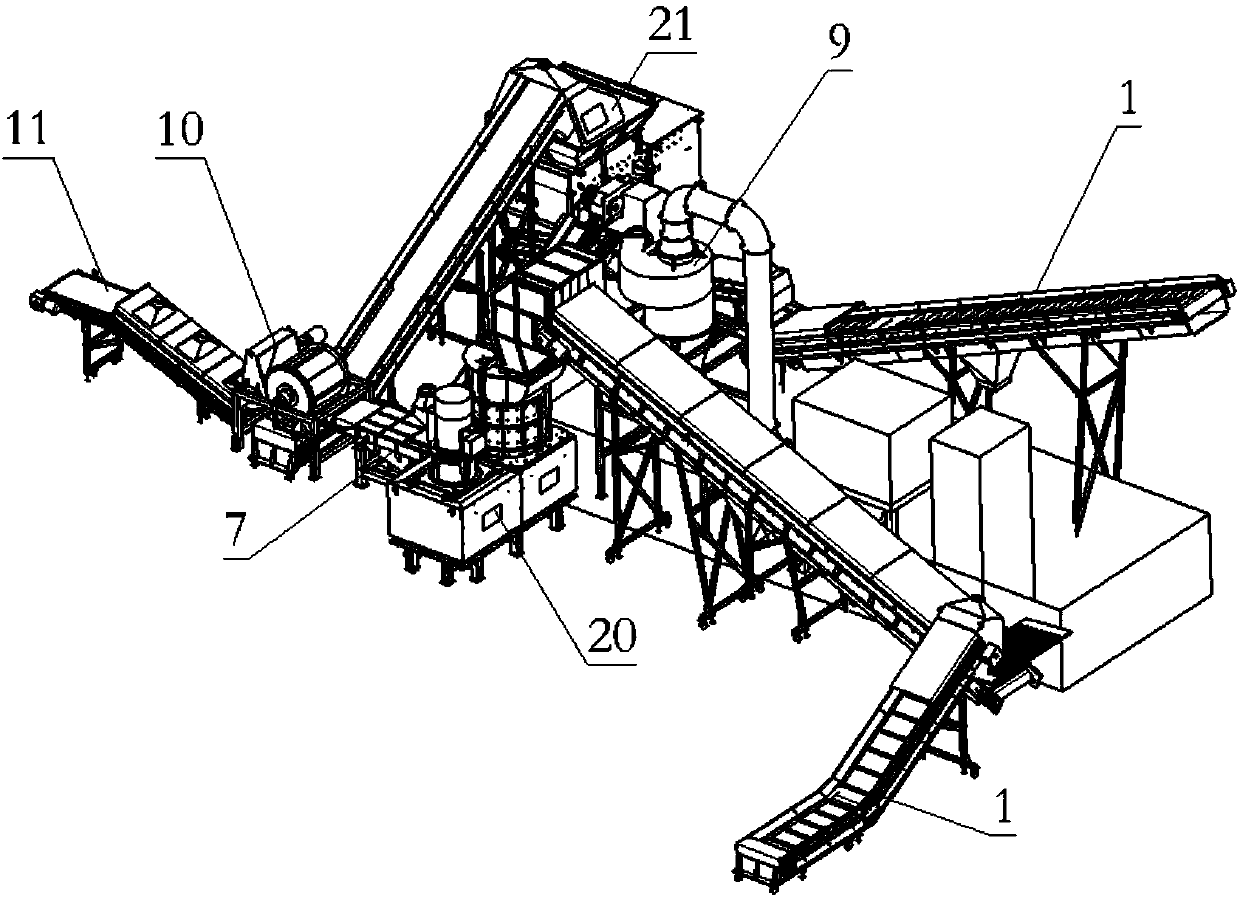

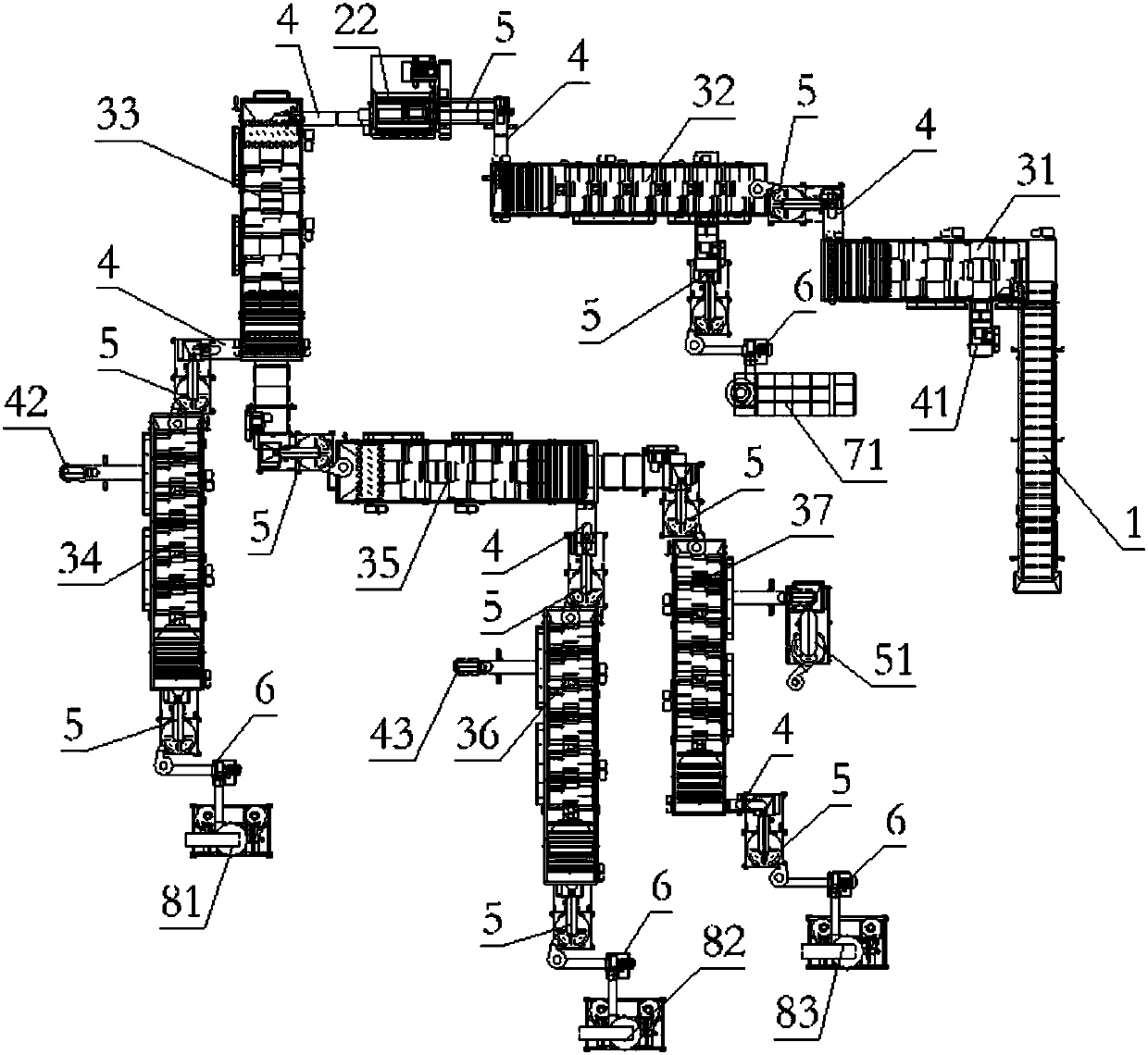

[0049] Referring to Figure 1-12, a plastic recycling system includes a pre-screening and cleaning system and a screening and cleaning system; Figure 1a As shown, the screening and cleaning pre-order system is used to crush raw materials and filter metal impurities; the conveyor belt 1 is used to transport materials to the feeding ports of each equipment, and the conveyor belt 1 adopts a closed structure to prevent dust from spreading; Figure 1b As shown, the crusher 2 in the screening and cleaning pre-order system is specifically the first crushing device 20 (combined with Figure 1b , Figure 1a The crusher 2 in the above refers to the first crushing device 20), which is used to receive the material transported by the conveyor belt 1, break the material and transport it to the separation and sedimentation tank 3. In a preferred emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com