Aluminum formwork construction technology

A construction technology and aluminum formwork technology, which is applied in the direction of formwork/formwork/work frame, formwork/formwork components, and on-site preparation of building components, which can solve the problems of formwork construction difficulties, high construction costs, and difficult protection. Achieve the effects of reducing ills, improving work efficiency, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

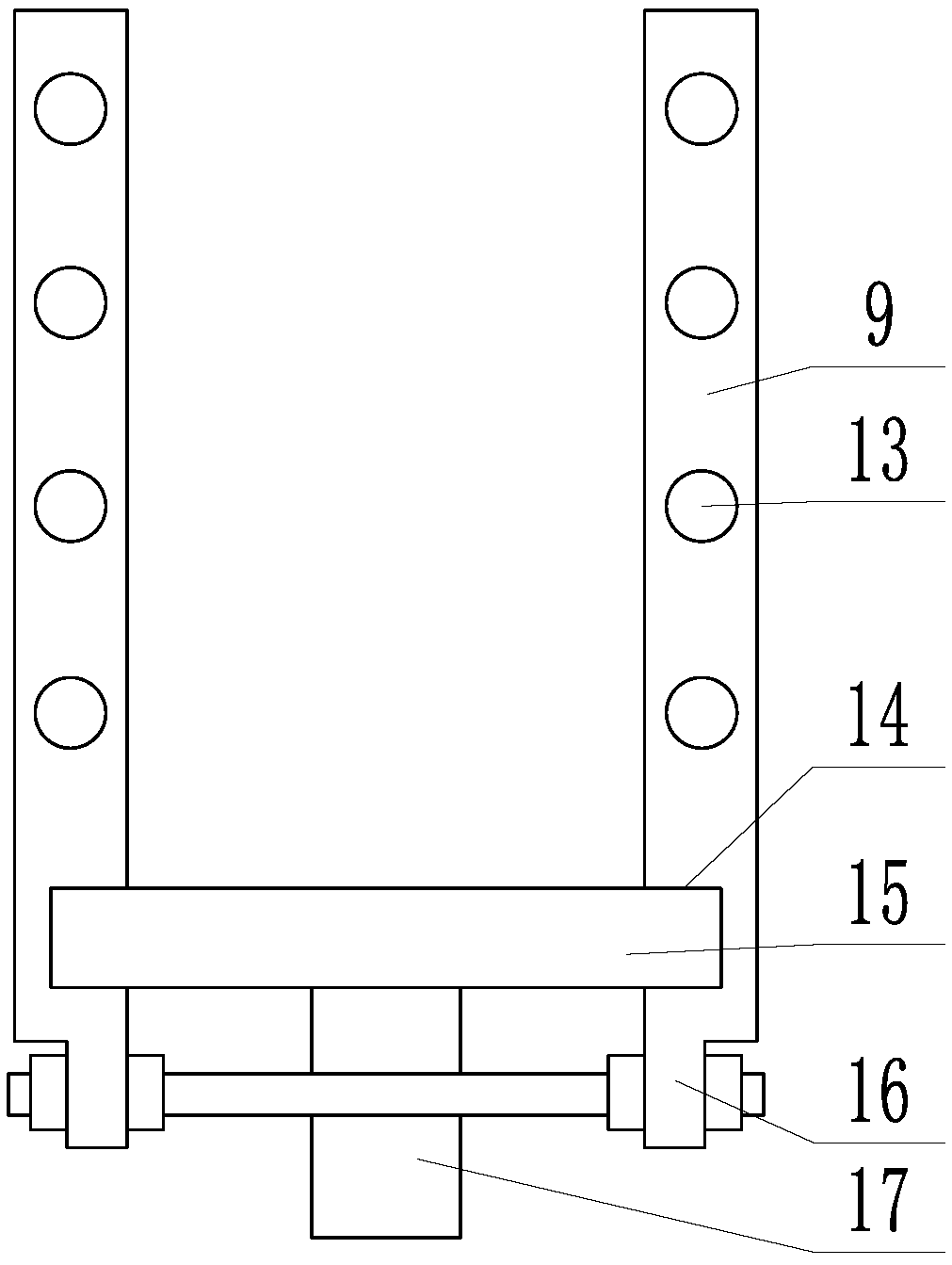

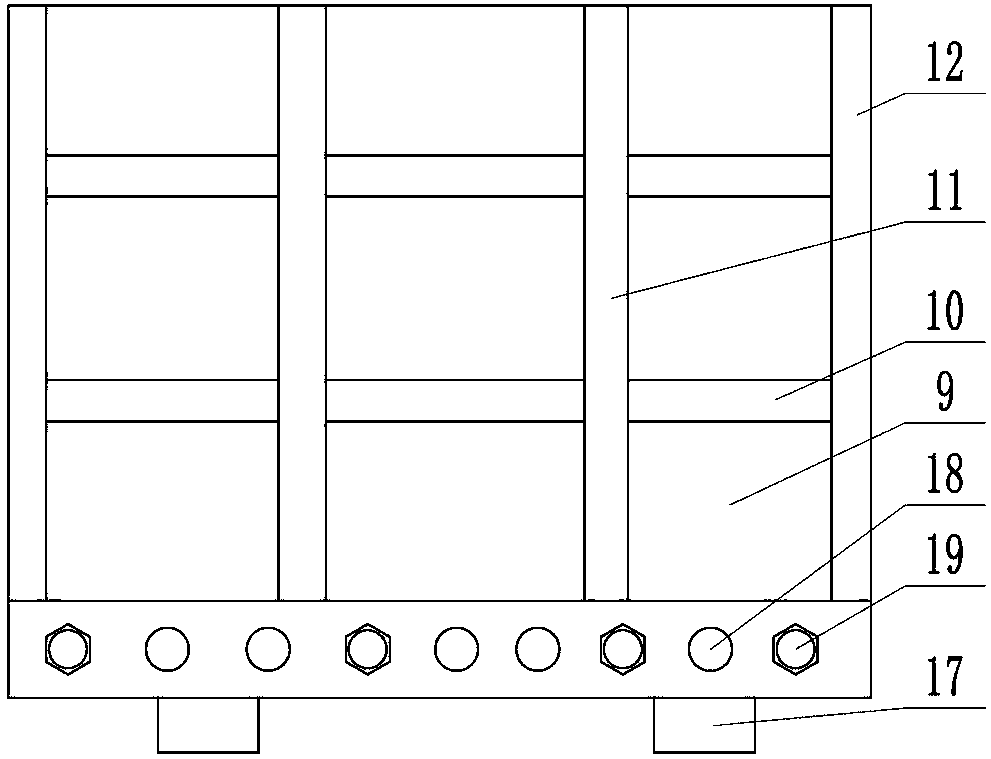

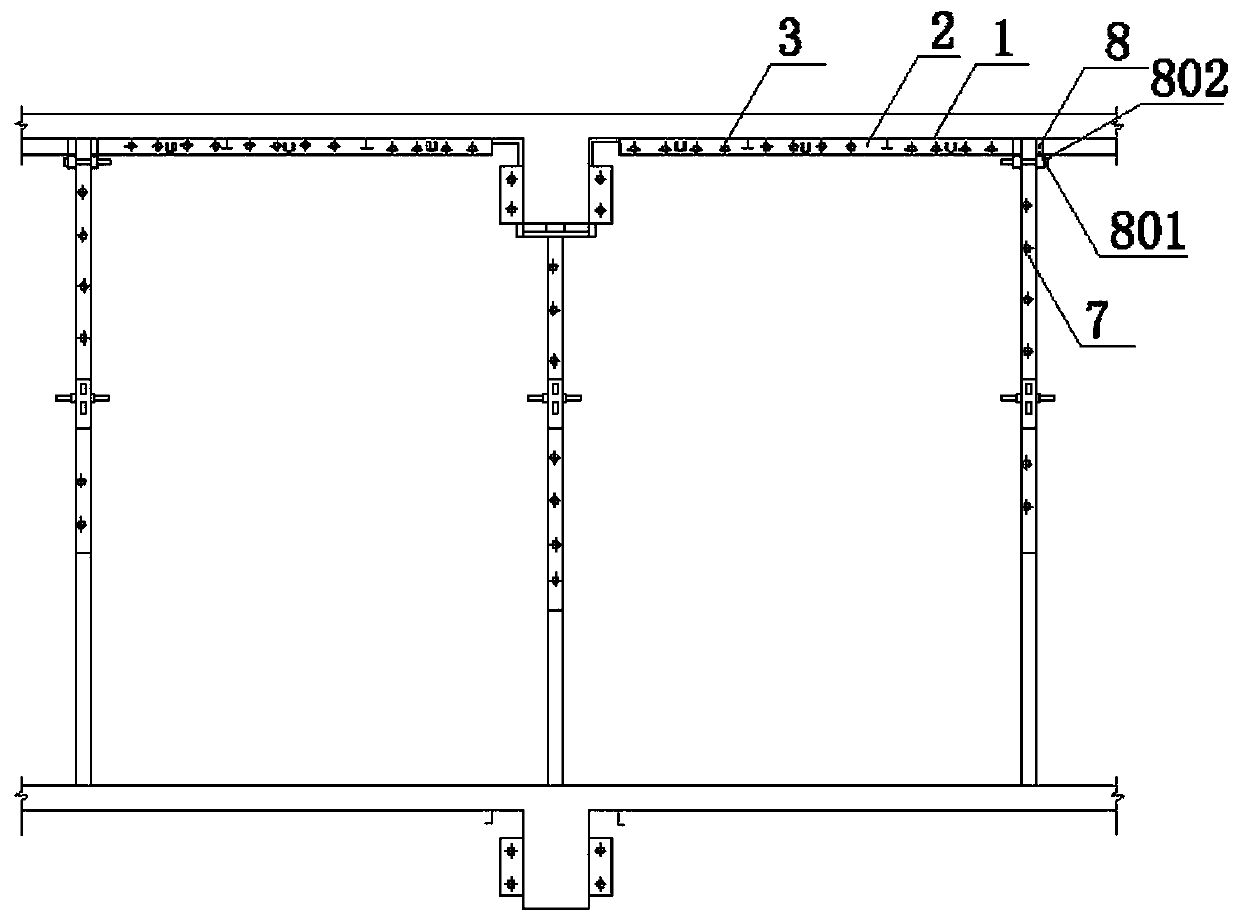

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Depend on Figure 1 to Figure 6 Given, the present invention comprises the steps:

[0020] Step 1: Determine the aluminum formwork design scheme: 1. Design beam formwork, 2. Design floor formwork, 3. Design wall column aluminum formwork system, 4. Design floor formwork and beam support system.

[0021] The second step: aluminum alloy formwork resource allocation.

[0022] Step 3: Measuring method: 1. Introductory measurement of floor axis, 2. Introductory measurement of floor elevation.

[0023] Step 4: Construction sequence: The construction sequence of standard layer formwork, steel bars, and concrete pouring is: wall and column reinforcement binding → aluminum alloy formwork installation → wall and column concrete pouring → beam slab reinforcement binding → aluminum alloy formwork installation → beam slab con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com