Patents

Literature

42results about How to "No change in intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

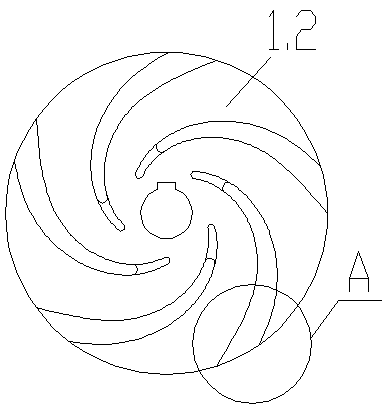

Machining method for three-dimensional flow impeller

The invention discloses a machining method for a three-dimensional flow impeller. An original whole forging of a wheel cover is changed into a panel, the wheel cover is formed through a die and spliced with an inlet ring in a welding manner, then, the wheel cover and blades manufactured in advance are spliced and formed, finally, a wheel disc and the wheel cover are welded and formed, and finish turning is carried out after thermal treatment. An impeller and the blades are independently manufactured and spliced together through spliced welding. Compared with the traditional technology, by means of the whole forging forming, the integral strength cannot be changed, the consumption of raw materials is greatly reduced through the new technology, the machining difficulty is lowered, and the machining efficiency is improved.

Owner:湖北双剑鼓风机股份有限公司

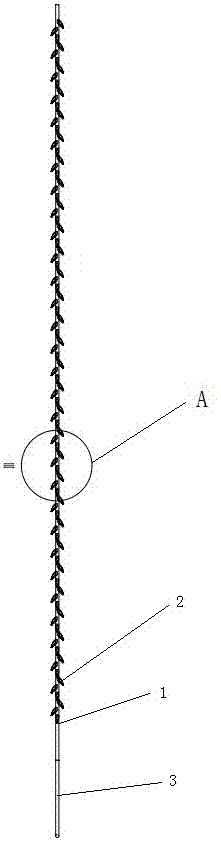

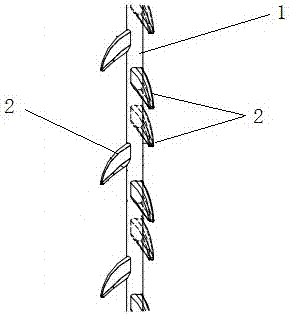

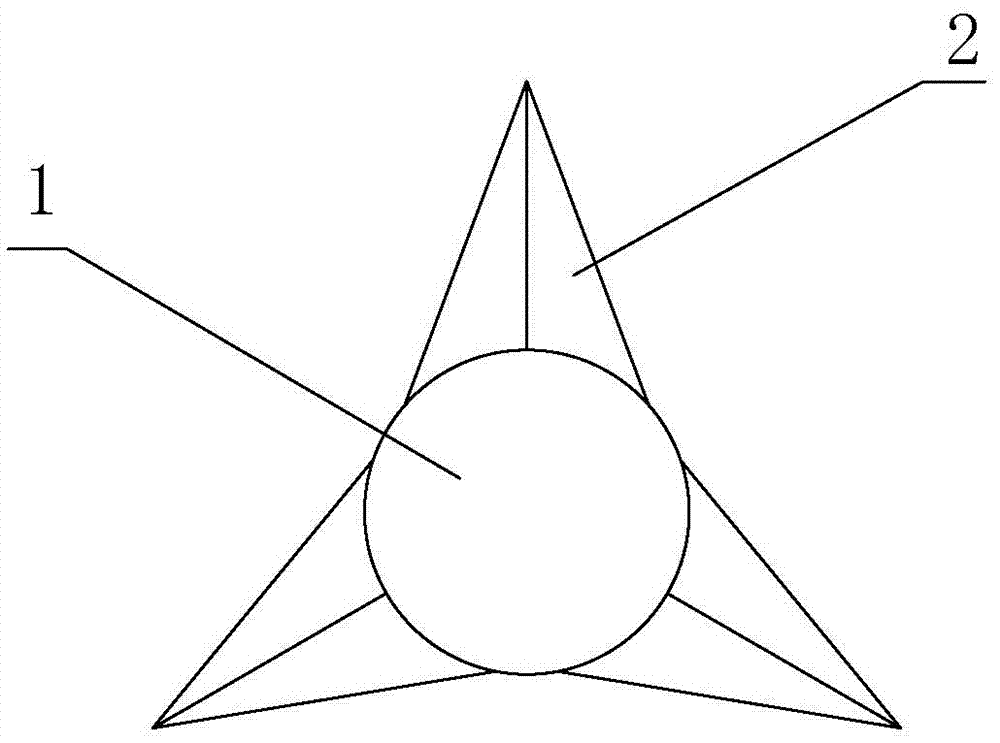

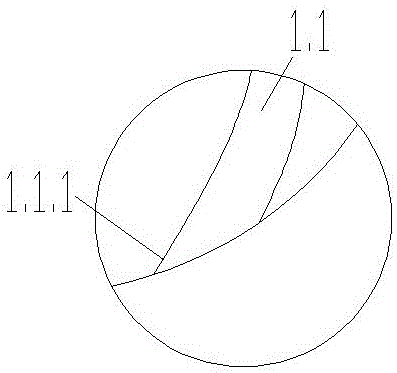

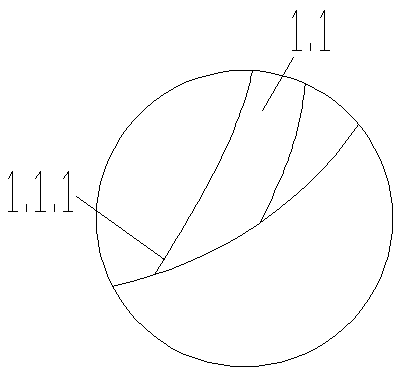

Cosmetic barb string

The invention discloses a cosmetic barb string. The cosmetic barb string is characterized by comprising a string body (1) made of PCL or PP or PLGA, the peripheral side wall of the string body (1) is provided with 3-5 rows of barbs (2), the string body (1) and the barbs (2) are integrally formed through the hot-pressing injection molding process, one barb in one row of barbs (2) and two adjacent barbs in the other two rows of barbs (2) are spirally distributed on the peripheral side wall of the string body (1), the two ends of the string body (1) are each provided with a smooth section without barbs, and the barb body of each barb (2) is a triangular prism, wherein the barb tips are bent in the same direction. In the use process of the cosmetic barb string, general anesthesia is not needed, the cosmetic barb string is implanted in the cortex of the human body through a minimally invasive incision, no scar is left, the effect is improved and is natural and lasting, and the cosmetic barb string is especially suitable for people who refuse surgery or can not undergo surgery but need cosmetology. The cosmetic barb string can be absorbed by the human body and gradually degraded and metabolized without residues, is safe to the human body and guarantees the safety without worries about future.

Owner:王月玲

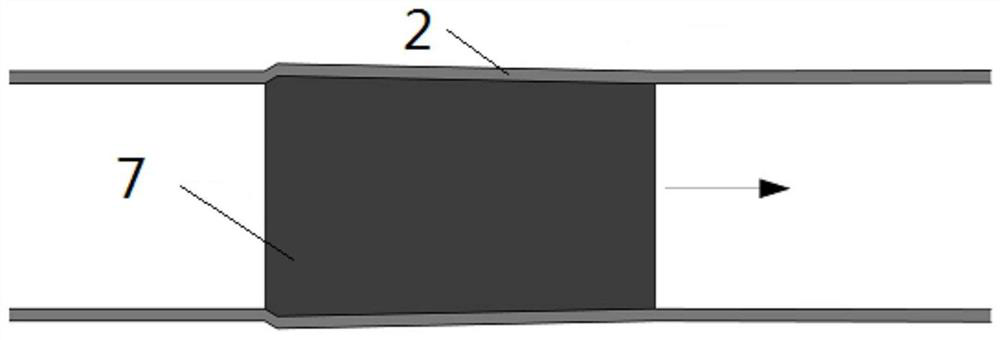

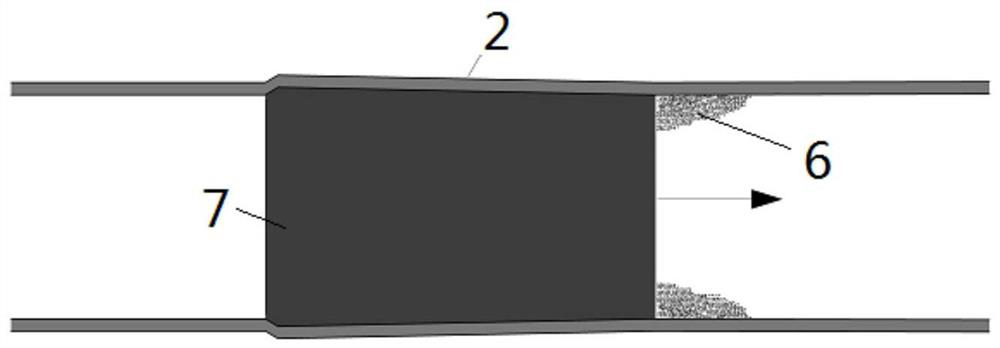

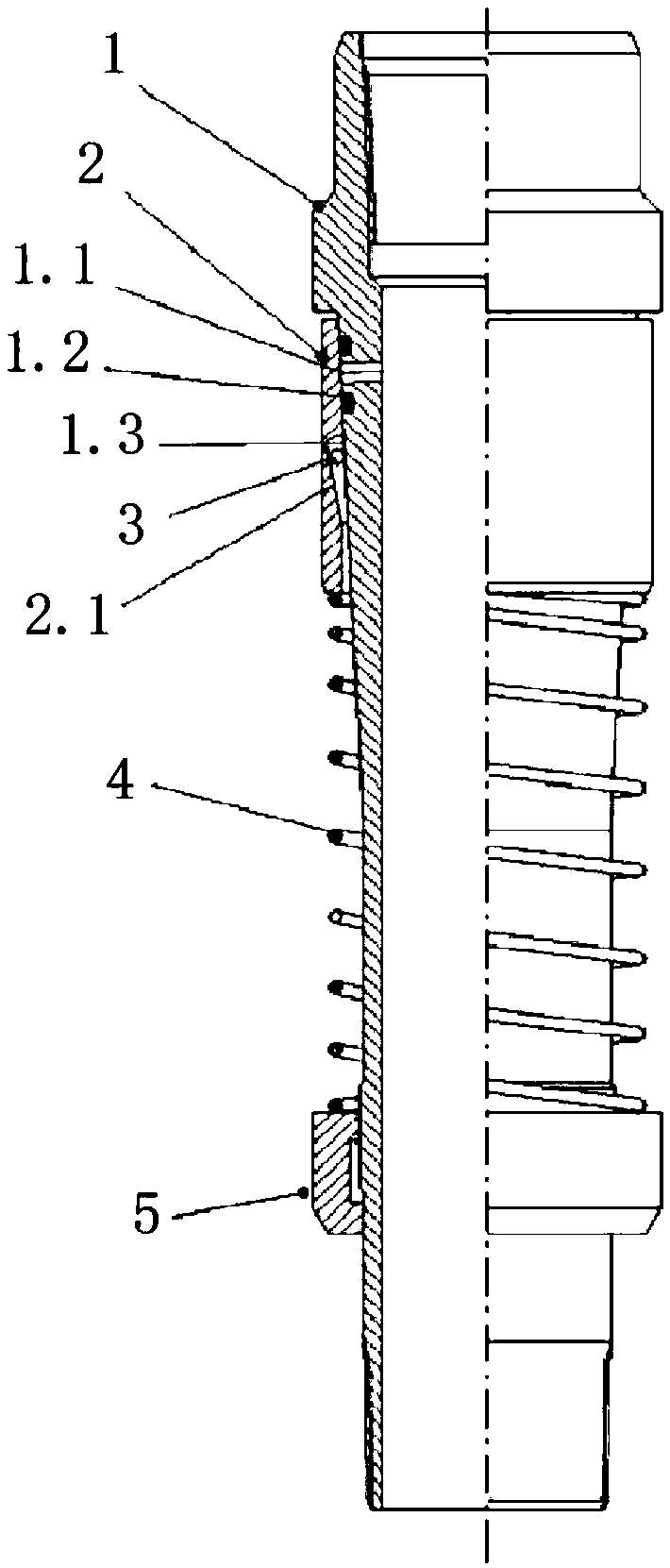

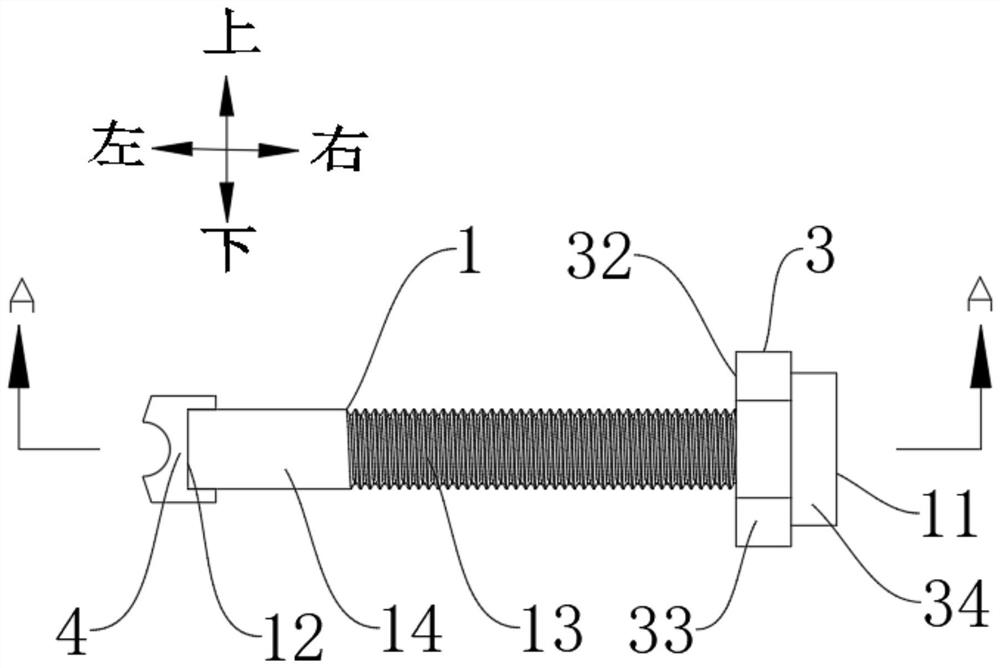

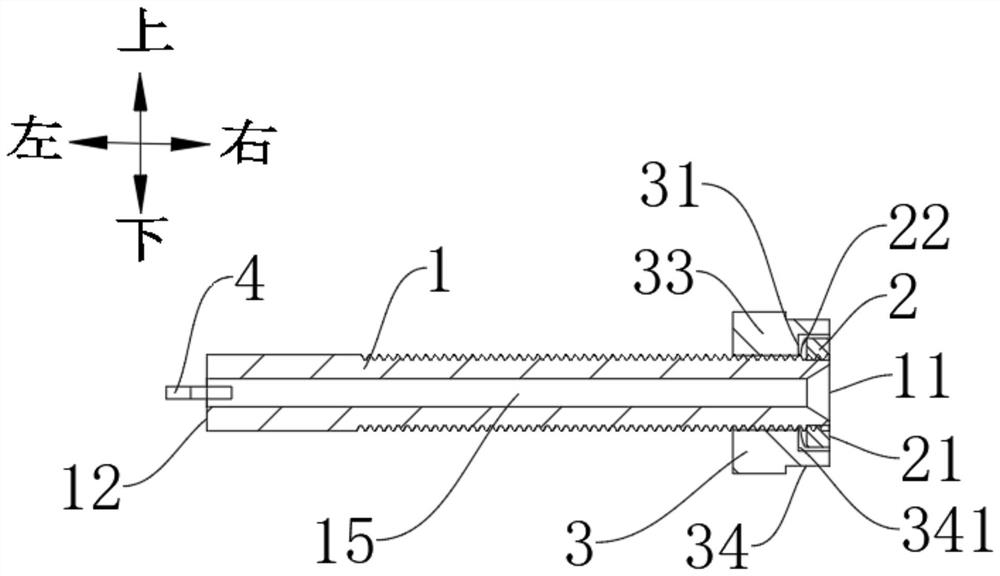

Assembly with constant-resistance body and constant-resistance sleeve and NPR anchor rod/cable

The invention provides an assembly with a constant-resistance body and a constant-resistance sleeve and an NPR anchor rod / cable. The assembly with the constant-resistance body and the constant-resistance sleeve comprises the constant-resistance body, and the constant-resistance sleeve, wherein the constant-resistance body is in a circular truncated cone shape, and the constant-resistance body is provided with a large diameter end and a small diameter end; the constant resistance body is arranged inside the constant resistance sleeve; the radial size of the large diameter end of the constant-resistance body is larger than the inner diameter of the constant-resistance sleeve, and the radial size of the small diameter end of the constant-resistance body is less than the inner diameter of theconstant-resistance sleeve; and grooves are formed in the edge of the end surface of the large diameter end of the constant-resistance body. In the sliding stage, scrap iron originally generated and accumulated at the front end of the constant-resistance body can be gradually discharged through the grooves in the forward sliding process of the constant-resistance body and cannot be accumulated atthe front end of the constant-resistance body any more to hinder sliding movement of the constant-resistance body, the constant constant-resistance value of the NPR anchor rod / cable in the working process is guaranteed, and the important practical significance is achieved for deformation control of the engineering rock mass.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Laser etching manufacturing method of large annular component

ActiveCN108326441AUniform coatingCoating error is smallLaser beam welding apparatusLaser etchingSurface cleaning

The invention provides a laser etching manufacturing method of a large annular component. The method is used for machining an aerospace component with the diameter not less than 1.2 m, and mainly comprises the steps of carrying out surface cleaning on the component, soaking the cleaned component in etching paint, and then taking out the component after soaking is carried out for one hour; puttingthe component into a uniform stirring dryer, and taking out the component after one hour; carrying out primary clamping on the component, and taking four positioning points on the end surface of the component; performing primary laser etching, using a laser mechanical arm to etch on the etching paint on the component surface according to a preset etching pattern, and forming a machining pattern onthe etching paint of the component surface; and immersing the etched component in a corrosion pool, and machining the component through a corrosion solution in the corrosion pool, so that the position, where the etching paint is etched through laser etching, of the surface of the component is exposed in the corrosion solution and becomes thinner after being corroded by the corrosion solution, andthe etching paint which is not subjected to the laser etching still covers the surface of the component to prevent corrosion of the corrosion solution.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

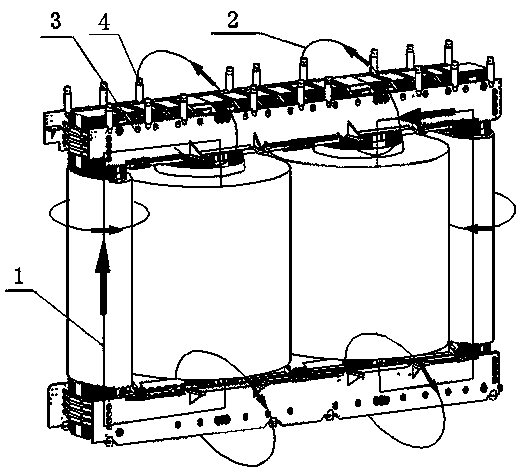

External circulation bypass structure between converter transformer core pulling plate columns

InactiveCN103745813AReduce lossImprove eddy current lossTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerPlate column

The invention relates to an external circulation bypass structure between converter transformer core pulling plate columns, in particular to a circulation bypass structure between large-capacity converter transformer core pulling plate columns, and belongs to the technical field of transformer manufacturing. According to the technical scheme, a plurality of copper cables (4) are arranged in a conductor grip frame (3), the copper cables are connected with coil outgoing wires and then connected with an upper clamp and a lower clamp, and the copper cables, the upper clamp, the lower clamp and core main column pulling plates form short circuit rings (2) along core windows. The external circulation bypass structure has the advantages that on the premise that the structure and the strength of the pulling plates are not changed, losses of the pulling plates are reduced, eddy current losses of cores are greatly reduced, leakage flux is restrained, the structure is simple, and layout is reasonable.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

Method for spraying wolfram carbide alloy on seal surface of valve plate (seat) at supersonic speed

The invention discloses a method for spraying a wolfram carbide alloy on a seal surface of a valve plate (seat) at a supersonic speed. The method is characterized in that supersonic spraying equipment is adopted to spray the wolfram carbide alloy on the seal surface of the valve plate (seat); the sprayed wolfram carbide alloy coating is dense and meets the airtightness requirement; the coating hardness HV (Vickers hardness) is not less than 1100; the coating void ratio is not more than 1%; the coating bonding strength is not less than 10000PSi; and the coating thickness is more than 0.15mm. The method has the following advantages: through supersonic spraying, the coating and a matrix structure are not subjected to high temperature and deformation; preheating and postweld heat treatment are not needed; lathing is not needed after welding; the method is suitable for batch (non-singleton) production; and the production efficiency is high.

Owner:JIANGSU JINSHI TECH CO LTD

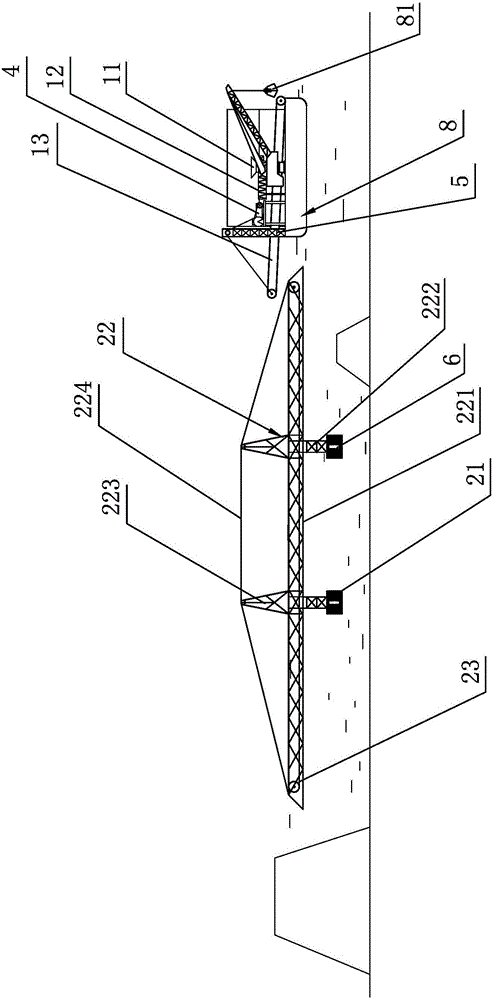

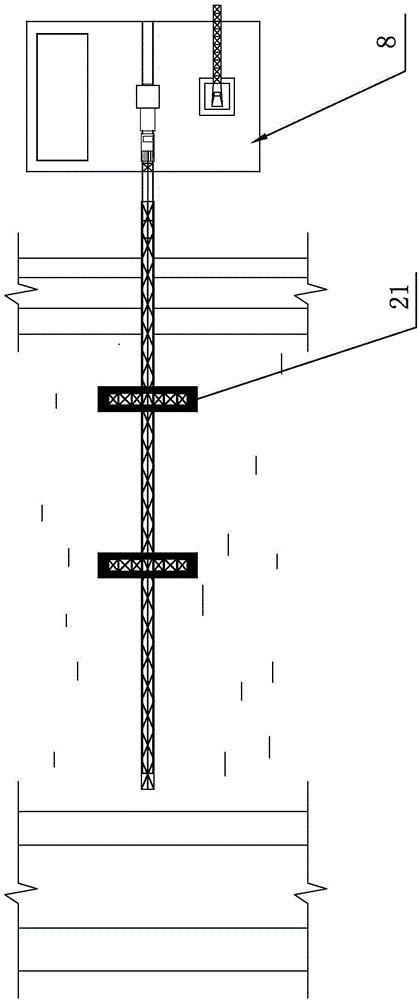

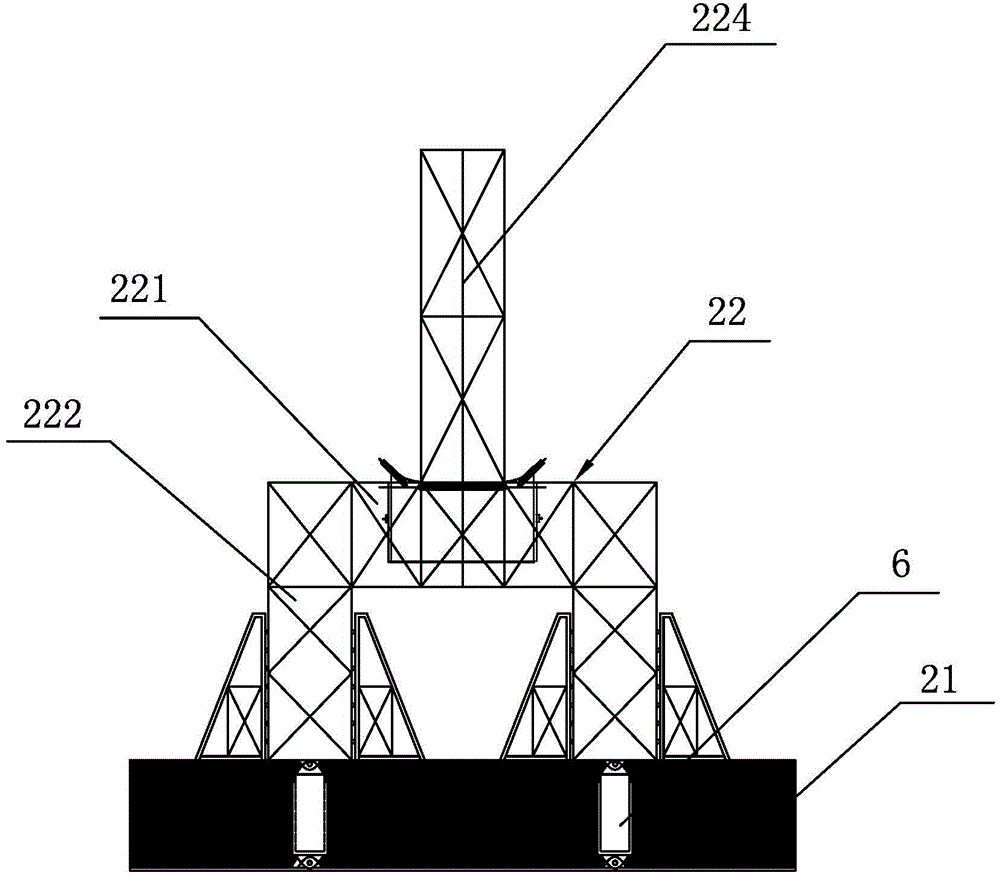

Sludge conveying system

InactiveCN104355127AThe scope of soil extraction is not limitedReduce lossStorage devicesSludgeEngineering

The invention discloses a sludge conveying system, which comprises a grab dredger, an auxiliary conveying mechanism and a main conveying mechanism, wherein the grab dredger works on water, the auxiliary conveying mechanism is arranged on the grab dredger, the main conveying mechanism works in a backfilling region, the auxiliary conveying mechanism consists of a hopper, a spiral conveyer and an auxiliary belt conveyor, a feeding opening of the hopper receives sludge grabbed by a grab of the grab dredger, a discharging opening of the hopper is connected with a feeding opening of the spiral conveyer, a discharging opening of the spiral conveyer is positioned right above a belt of the auxiliary belt conveyor, the tail end of the auxiliary belt conveyor is hung outside the grab dredger, the main conveying mechanism consists of a plurality of flat bottom floating bodies, a steel truss and a main belt conveyor, the flat bottom floating bodies are flatly placed on the backfilling region, the steel truss is erected on the flat bottom floating bodies, the main belt conveyor is arranged on the steel truss, the tail end of the auxiliary belt conveyor is positioned right above the belt of the main belt conveyor. The sludge conveying system has the advantages that the automation degree is high, the conveying efficiency can reach 300 to 600m<3> per hour, and the conveying cost is low.

Owner:宁波高新区围海工程技术开发有限公司

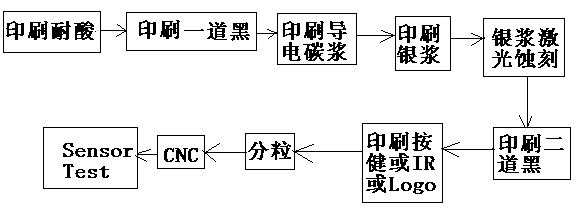

Manufacturing process for functional sheet of OGS (One Glass Solution) touch screen

InactiveCN103853410AThickness dropNo change in intensityInput/output processes for data processingNumerical controlGraphics

The invention discloses a manufacturing process for a functional sheet of an OGS touch screen. The manufacturing process comprises reinforcing, printing and making of a structural component CG of the touch screen, film plating of a functional component sensor, formation of patterns and cracking into small pieces. Through the processes of deep reinforcement of integrated glass, high-temperature film plating, CNC (Computer Numerical Control) cutting and the like, the overall thickness of the TP is reduced on the premise of not changing the performance such as the strength and function of the touch screen, but the manufacturing process is simpler, the cost is lower and the investment is smaller than the conventional OGS manufacturing process. The manufacturing process has the characteristics of simple process, easiness in implementation and low cost.

Owner:JIANGXI TIANYI PHOTOELECTRIC

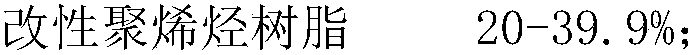

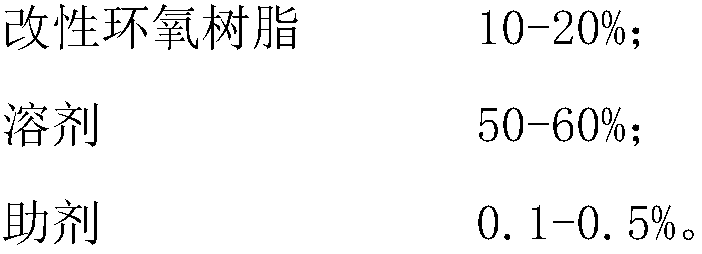

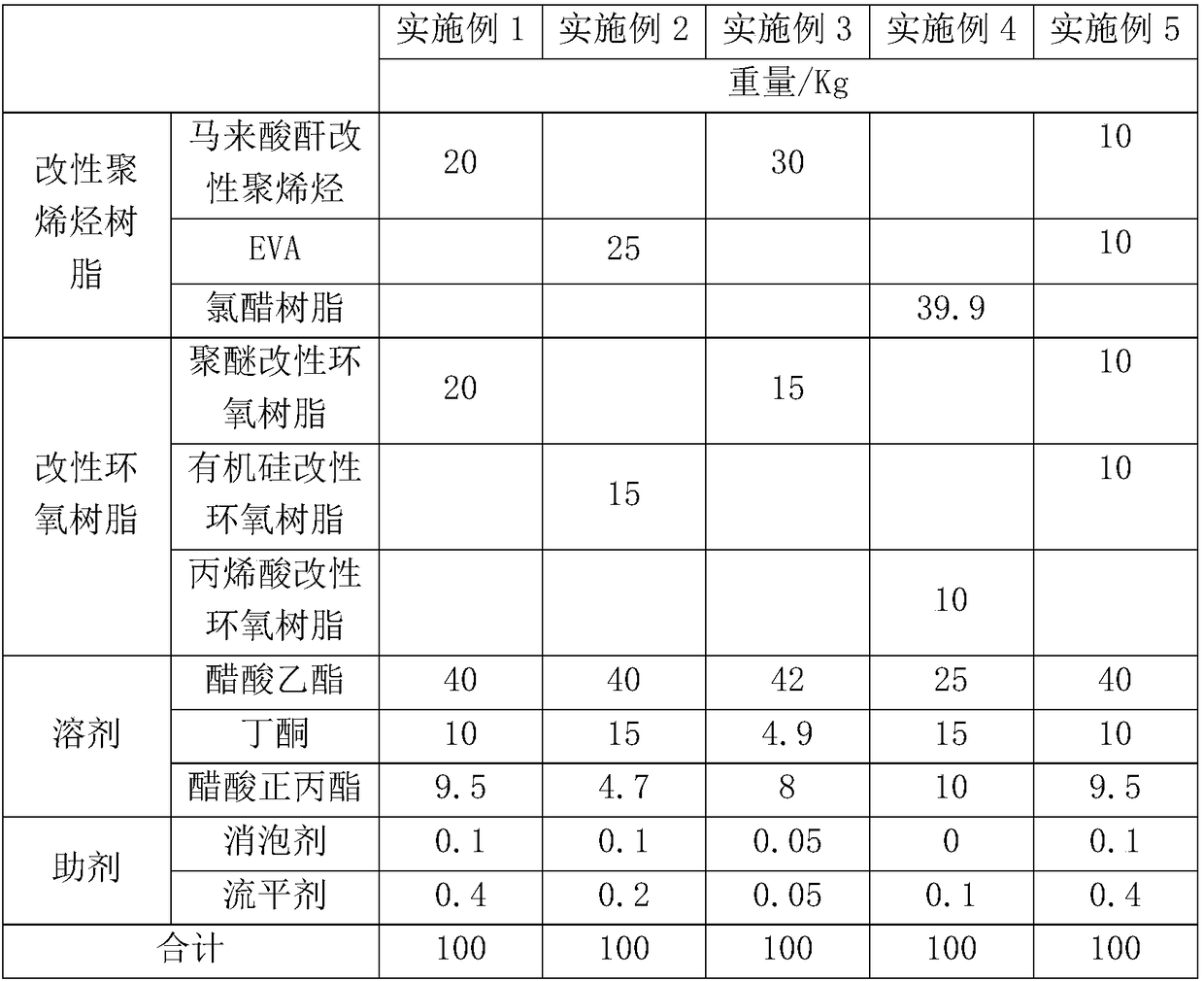

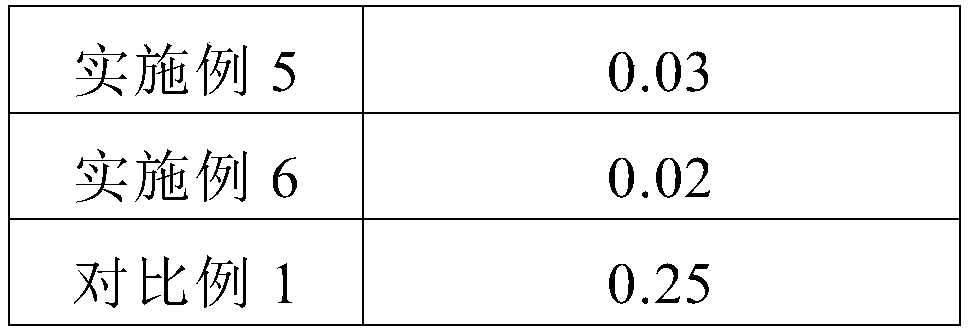

High temperature-resistant heat-sealing adhesive for high-speed medicine packaging machine for medicine blister packaging, and preparation method thereof

ActiveCN108264874ANo leaksNo wrinkle marksModified epoxy resin adhesivesGraft polymer adhesivesEpoxyPolyolefin

The invention provides a high temperature-resistant heat-sealing adhesive for a high-speed medicine packaging machine for medicine blister packaging. The high temperature-resistant heat-sealing adhesive comprises, by mass, 20-39.9% of modified polyolefin resin, 10-20% of modified epoxy resin, 50-60% of a solvent and 0.1-0.5% of an assistant. A preparation method of the high temperature-resistant heat-sealing adhesive comprises the following steps: S1, adding the solvent into a reaction kettle, performing stirring to achieve uniform mixing, sequentially adding the modified polyolefin resin andthe modified epoxy resin while stirring, and stirring and uniformly mixing the solvent, the modified polyolefin resin and the modified epoxy resin; S2, adding the assistant to a mixed solution obtained in step S1, performing high-speed stirring to achieve uniform mixing, and performing downtime curing; and S3, measuring the solid content, adjusting the solid content to a theoretical value, and performing stirring, cooling and filtering. Compared with heat-sealing adhesives in the prior art, the heat-sealing adhesive in the invention has the following advantages: no leakage sealing, no scorching crease marks and no peculiar smell are achieved during high-temperature and high-speed sealing using the medicine packaging machine; the heat-sealing strength is high, so product demands are met; anadhesive layer has a good stability, and the strength of a coating film does not change after the coating film is stored for one year; and the heat-sealing adhesive has a wide application range.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Method for machining wheel cover and wheel disc of double bracing blower wheel

A method for machining a wheel cover and a wheel disc of a double bracing blower wheel comprises the steps of wheel disc and inlet ring blanking, wheel cover mold profiling, inlet ring turning, thermal treatment, inspection, wheel disc and shaft disc blanking, shaft disc turning, wheel disc and shaft disc welding, weld root overlap removal, thermal treatment, inspection and the like. According to the method, the quality is reliable, raw materials are saved, and production cost is reduced.

Owner:湖北双剑鼓风机股份有限公司

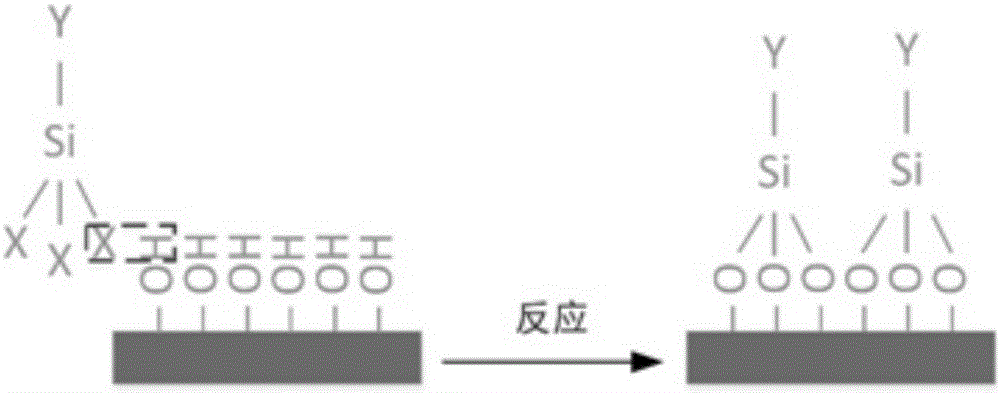

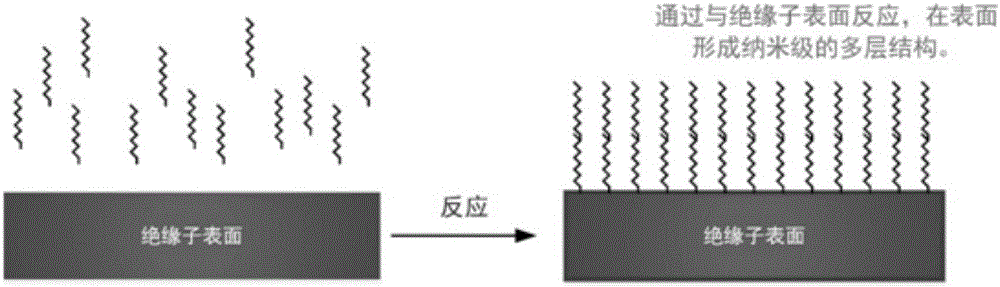

Self-cleaning high-strength bar-shaped porcelain insulator

The invention discloses a self-cleaning high-strength bar-shaped porcelain insulator. The insulator comprises an insulator body, and one or more nanometer molecular structure layers are arranged on the surface glaze layer of the body. The preparation method comprises the following steps: (1) diluting a functional material in ethanol solvent by a certain number of times to get impregnation liquid; and (2) dipping an insulator body into the impregnation liquid, hanging the insulator out after impregnation, growing one or more nanometer molecular structure layers on the surface of the insulator using long-chain unimolecules after the organic solvent on the surface of the insulator volatilizes, and finally, putting the insulator vertically on the ground and releasing a rope, thus obtaining the self-cleaning high-strength bar-shaped porcelain insulator. The advantage is as follows: by adding the nanometer molecular layers made of a membrane material to the surface of the insulator, the insulator has a good hydrophobic surface, contaminants can be hardly accumulated on the surface of the insulator, contaminants can be easily rinsed by rainwater after the insulator is contaminated, and the purpose of self-cleaning is achieved.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

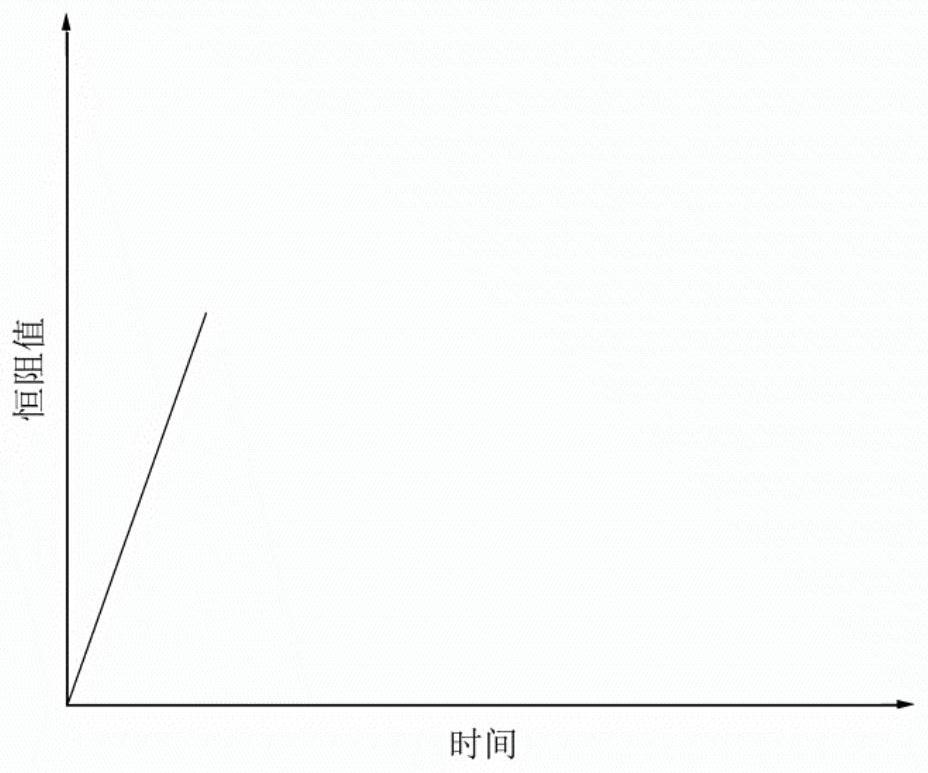

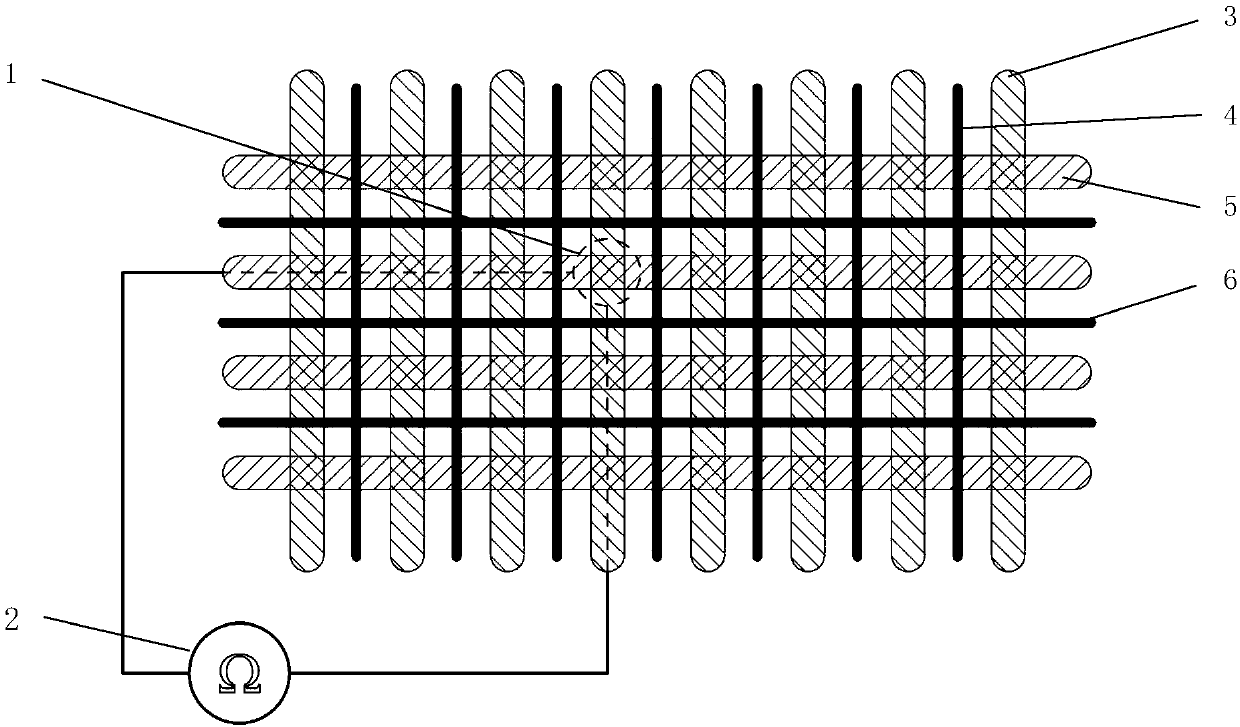

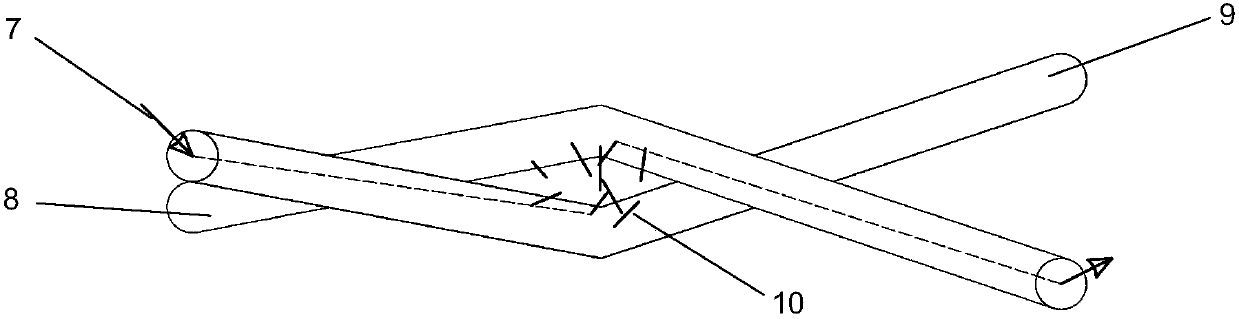

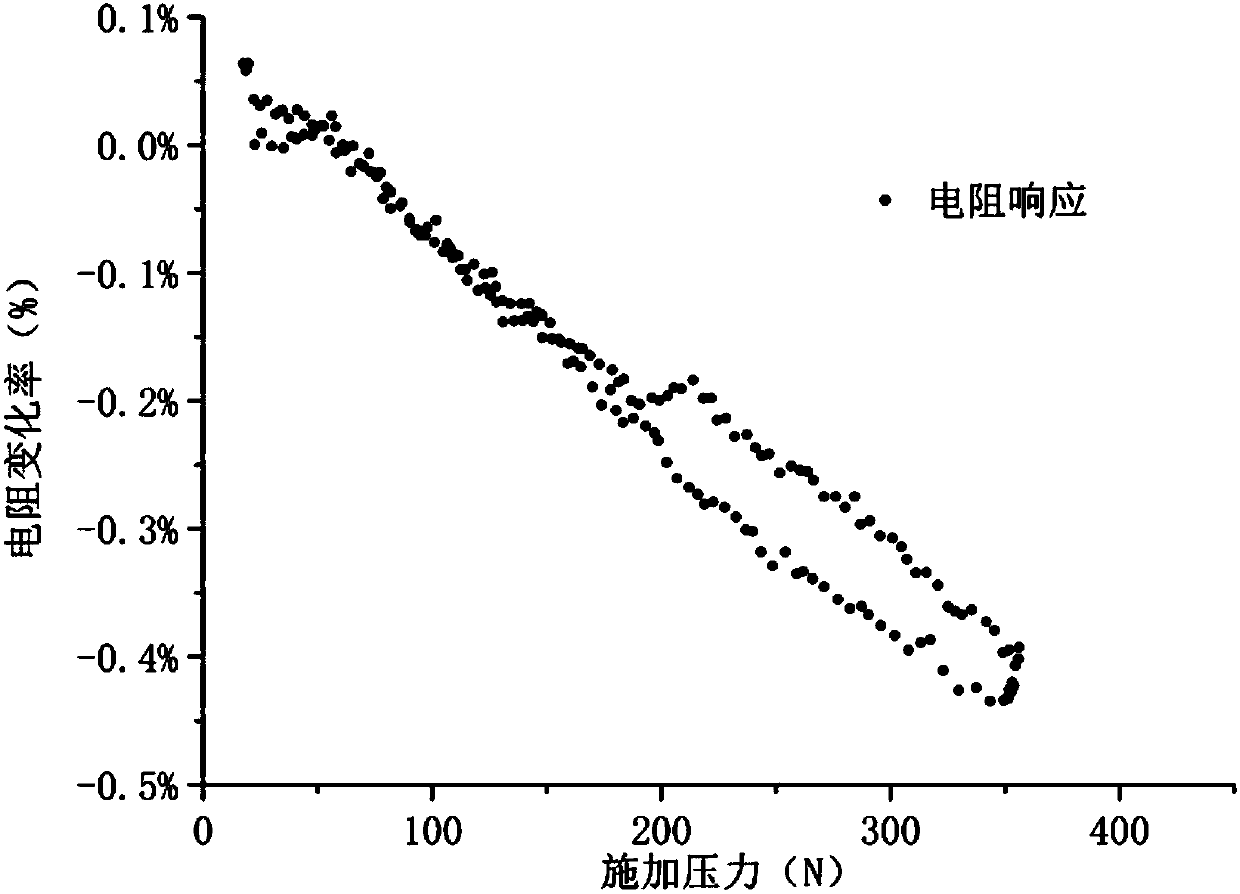

Pressure measurement sensitivity adjustment method

PendingCN107830950AChange intensitySensitivity adjustableFluid pressure measurement using ohmic-resistance variationForce measurementCarbon fibersCarbon nanotube

The invention discloses a pressure measurement sensitivity adjustment method. The method is aimed at a novel distributed pressure sensing element with a fiber-reinforced composite material as a sensitive material to adjust the sensitive relationship between the resistance change and external pressure. The method comprises the steps that in the process of manufacturing a fiber-reinforced fabric through a fiber weaving machine, the degree of tightness between carbon fibers in the fabric is changed by adjusting the yarn tension of a yarn carrier; in the process of polymer matrix injection moldingmanufacturing, conductive particles such as carbon nanotubes or carbon black are uniformly dispersed in a polymer fluid in proportion; and the density of the conductive particles in the gap between the carbon fibers is changed by adjusting the filling amount thereof. Based on the adjustments, the method can effectively change the initial resistance value and pressure-resistance variation relationship between the carbon fibers, and changes the measurement sensitivity of a pressure sensing element. The method provided by the invention can effectively adjust the sensitivity of the pressure measurement without substantially changing the overall strength of the composite material.

Owner:ZHEJIANG SCI-TECH UNIV

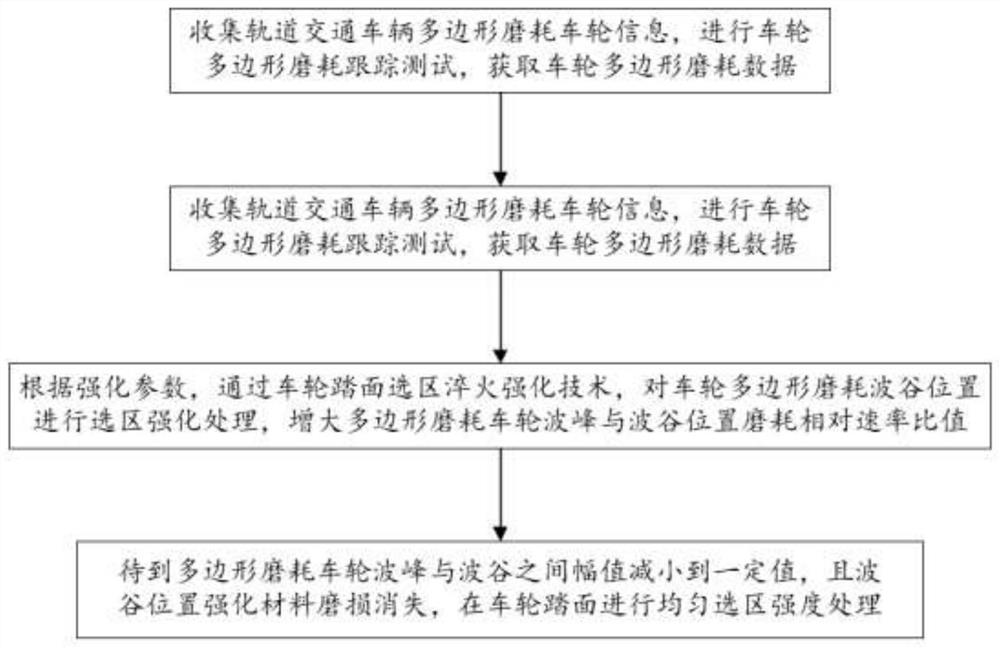

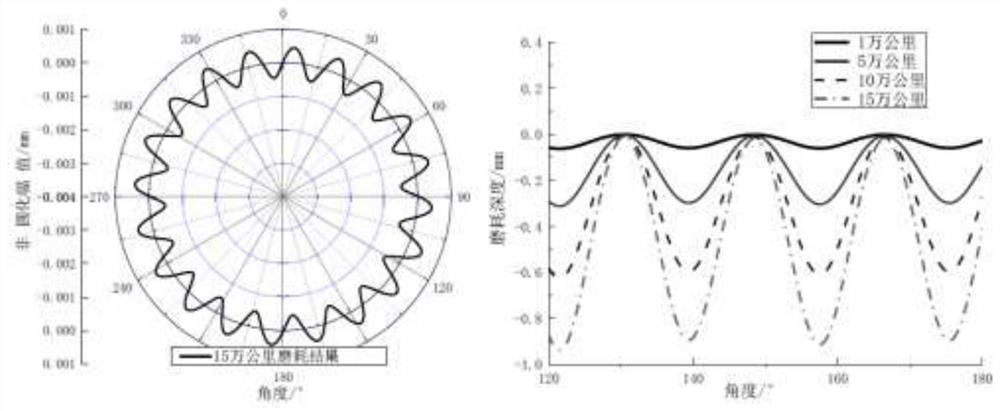

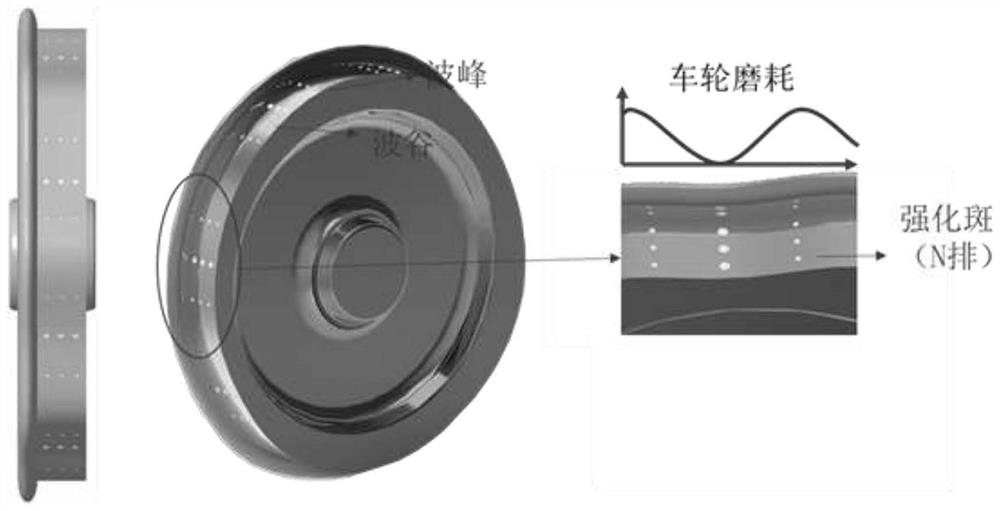

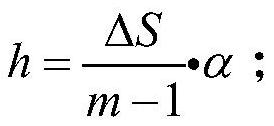

Method for controlling polygonal abrasion of wheels of rail transit vehicle

ActiveCN112749441AReduce the amplitudeIncrease the wear-to-rate ratioGeometric CADSustainable transportationStructural engineeringControl theory

The invention relates to the technical field of rail transit, in particular to a rail transit vehicle wheel polygon abrasion control method which comprises the following steps: 1, collecting information of a rail transit vehicle polygon abrasion wheel, and carrying out a wheel polygon abrasion tracking test to obtain wheel polygon abrasion data; 2, based on the wheel abrasion rate and the abrasion characteristic of a wheel tread quenching strengthening treatment material, matching and designing wave trough position wheel selective area strengthening parameters; 3, according to the strengthening parameters, through a wheel tread selective quenching strengthening technology, conducting selective strengthening treatment on the polygonal abrasion wave trough position of the wheel, and increasing the abrasion relative rate ratio of the wave crest position to the wave trough position of the polygonal abrasion wheel; and 4, when the amplitude between the wave crest and the wave trough of the polygonal abrasion wheel is reduced to a certain value and the abrasion of the strengthening material at the wave trough position disappears, performing uniform area selection intensity treatment on the wheel tread. According to the method, the development of polygon abrasion can be better controlled.

Owner:SOUTHWEST JIAOTONG UNIV +2

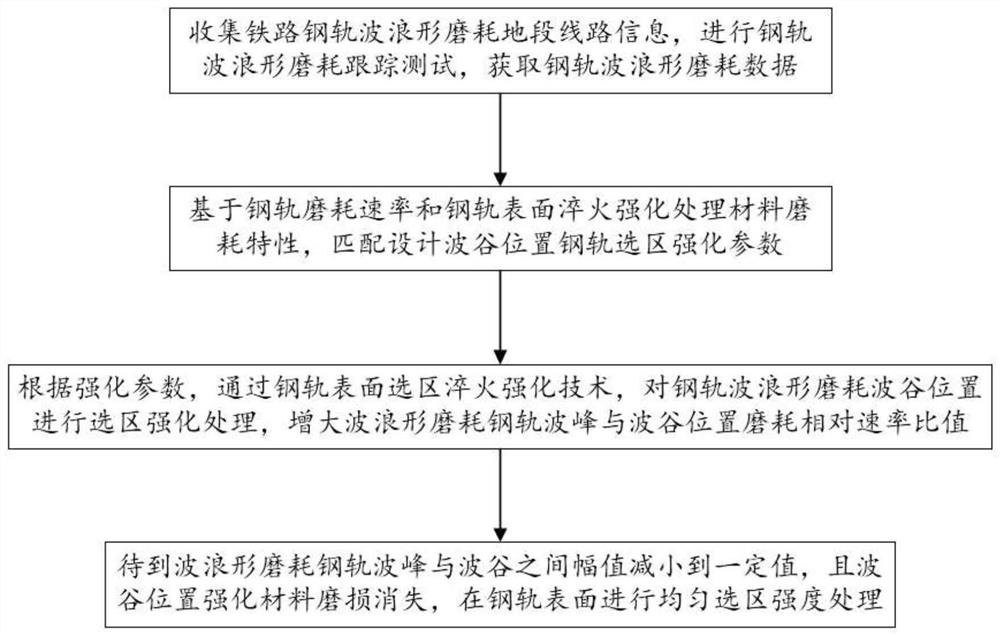

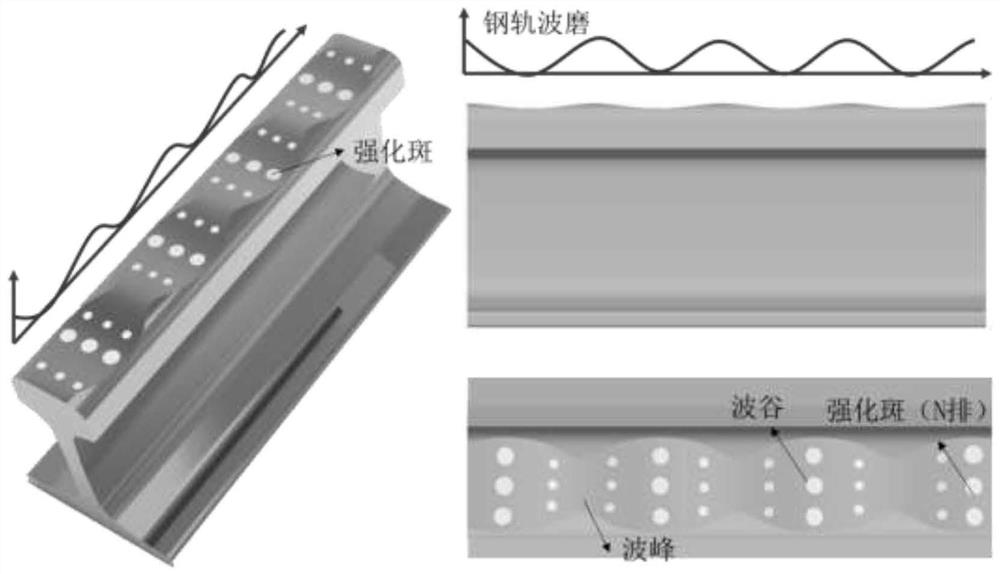

Railway steel rail undulating abrasion control method

ActiveCN112501965AGet wearChange intensityRailway track constructionMeasuring apparatusStructural engineeringUltimate tensile strength

The invention relates to the technical field of rail transit, in particular to a railway steel rail undulating abrasion control method which comprises the following steps that 1, railway steel rail undulating abrasion section line information is collected, a steel rail undulating abrasion tracking test is conducted, and steel rail undulating abrasion data is obtained; 2, based on the steel rail abrasion rate and the steel rail surface quenching strengthening treatment material abrasion characteristics, steel rail selected area strengthening parameters at the trough position are matched and designed; 3, according to the strengthening parameters, through the steel rail surface selective quenching strengthening technology, the wavy abrasion trough position of the steel rail is subjected to selective strengthening treatment, and the abrasion relative rate ratio of the wavy abrasion steel rail crest position to the wavy abrasion trough position is increased; and 4, after the amplitude between the wave crest and the wave trough of the wavy abrasion steel rail is reduced to a certain value and abrasion of the strengthening material at the wave trough position disappears, uniform area selection strength treatment is conducted on the surface of the steel rail. According to the invention, the development of wavy abrasion of the steel rail can be better controlled.

Owner:SOUTHWEST JIAOTONG UNIV +2

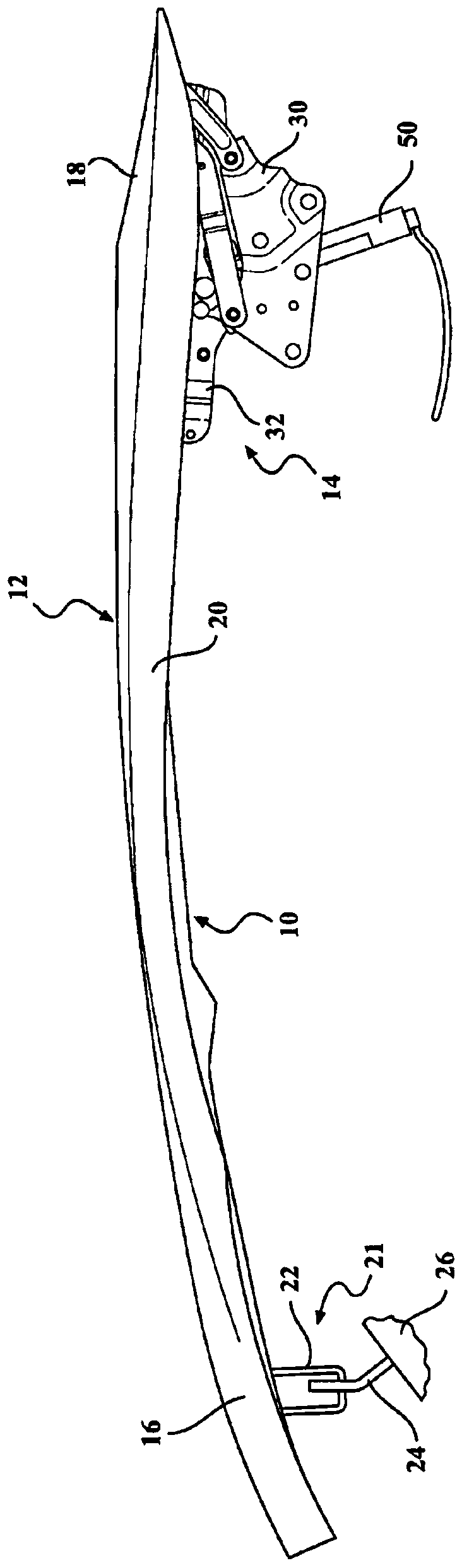

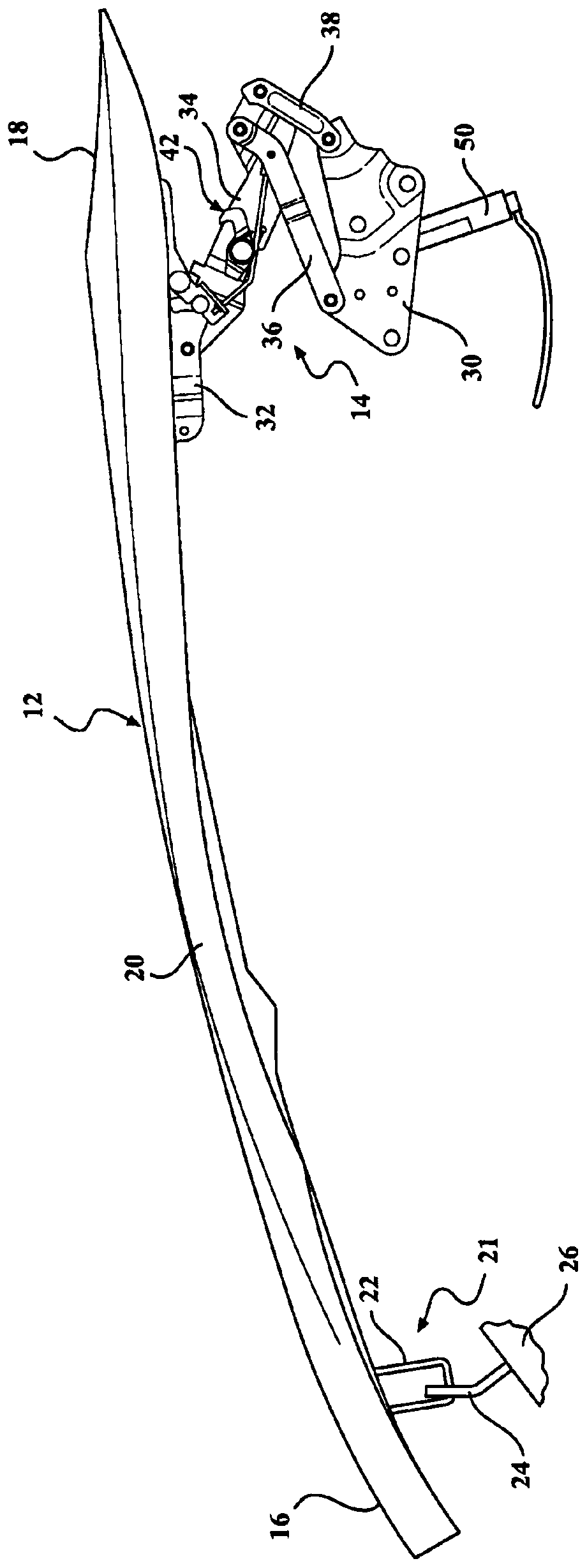

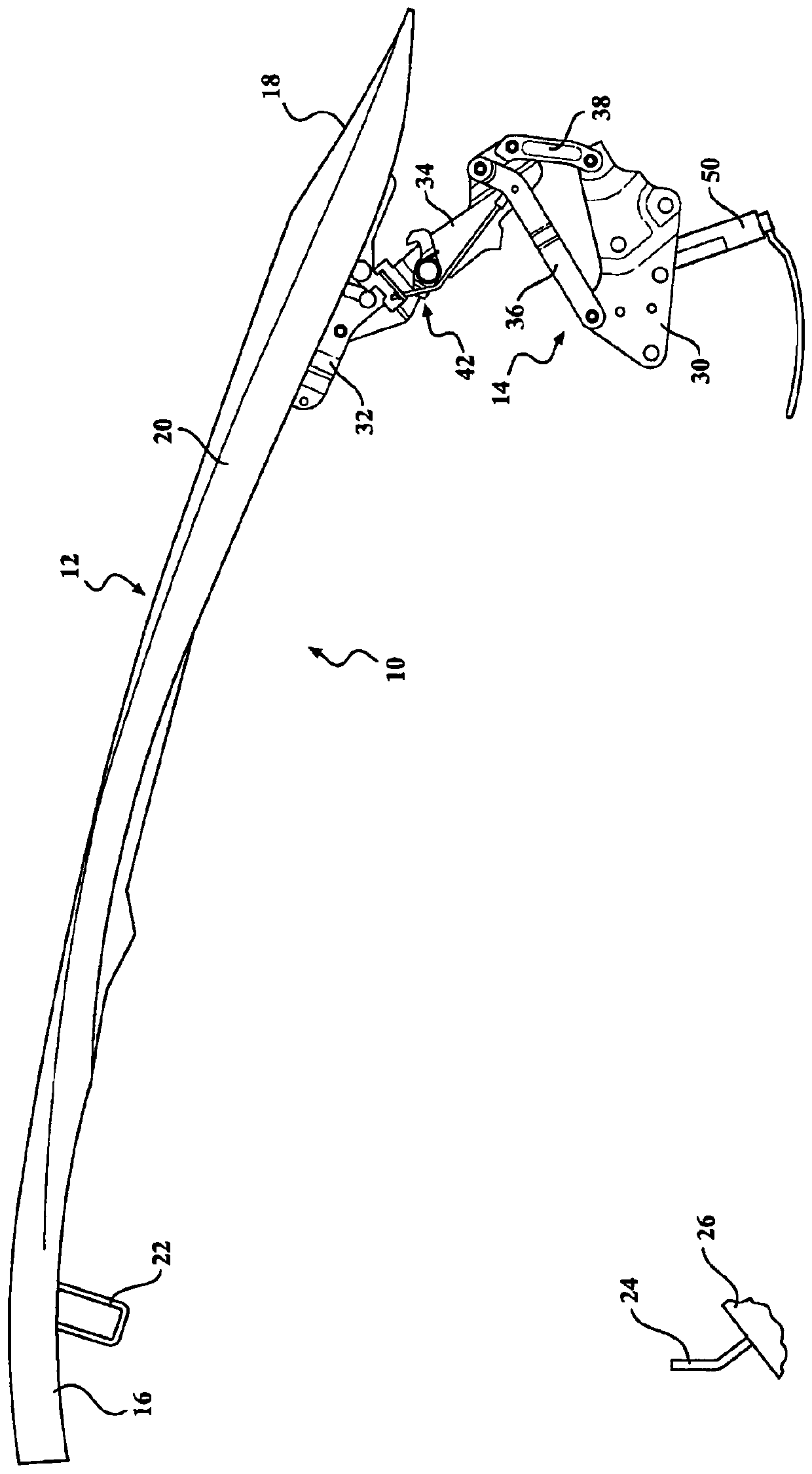

Light weight hinge

PendingCN110593695AIncrease strength and/or stiffnessAvoid deformation and fatiguePedestrian/occupant safety arrangementWing accessoriesAerospace engineeringHOOD assembly

The disclosure relates to a hinge for a hood assembly of the type used in motor vehicles. The hinge includes at least one structural composite component, attached to one of the hood and the body of avehicle, and configured to include a plastic portion overmolded into a core panel.

Owner:MAGNA BOCO GMBH

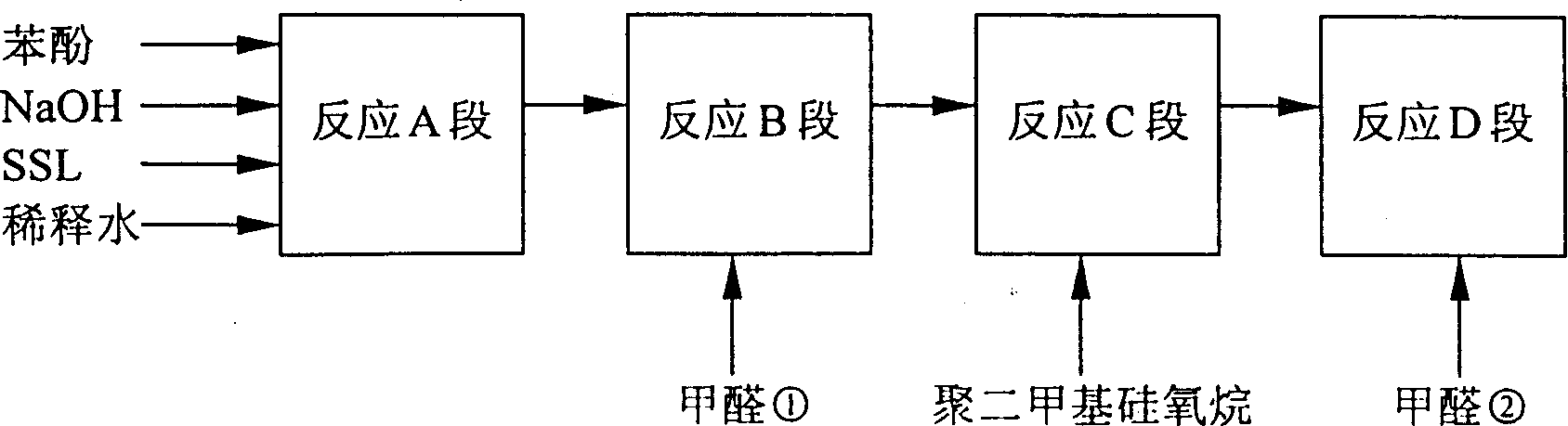

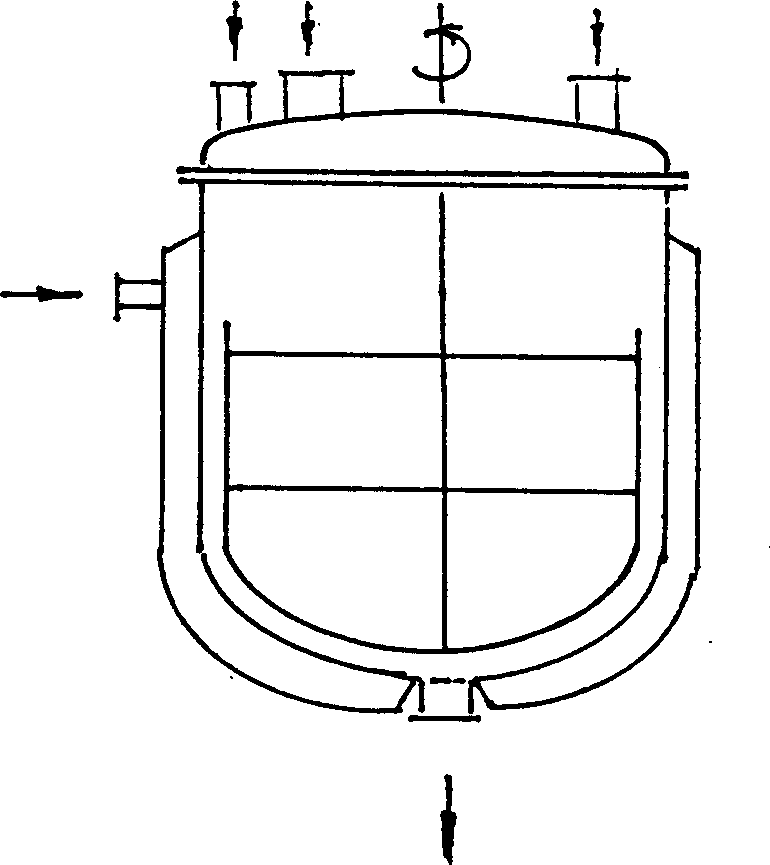

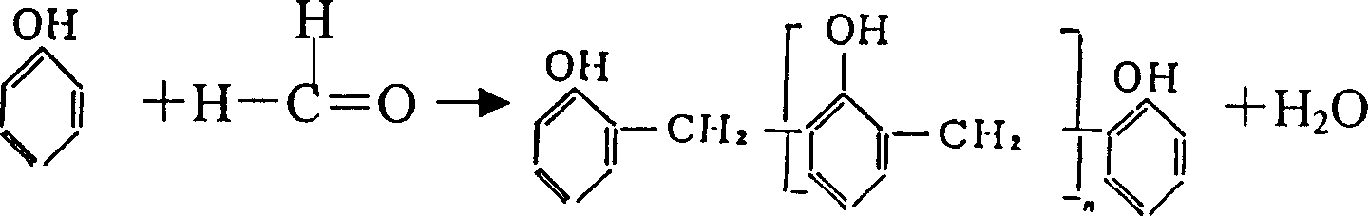

Composite phenolic resin glue producing method

InactiveCN1257244CWill not constitute pollutionMeet environmental protection requirementsAldehyde/ketone condensation polymer adhesivesReaction rateContamination

The invention discloses a production method of composite phenolic resin glue. NaOH is used as a catalyst, and phenol and formaldehyde are subjected to polycondensation reaction under normal pressure. Ratio: The molar ratio of phenol to formaldehyde is 1:1.7~2.23, the weight ratio of sodium lignosulfonate SSL, NaOH, dilution water to phenol is 1:0.8~1.16; the reaction speed is controlled by polydimethylsiloxane , The reaction is carried out in four sections in a reactor. Its advantage is that there is no formaldehyde and phenol sewage treatment problem in the production process, and it will not pollute the environment. Only 160-180kg phenol is used to produce one ton of composite phenolic resin glue, and the production cost is reduced by 20%-30%. Adding it overcomes the shortcomings of high brittleness and high shrinkage of the general phenolic resin glue used as an adhesive to press the board. Experiments show that the strength of the board does not change after being boiled in boiling water for 4 hours, and the board is placed outdoors for four months without cracking.

Owner:曲韵丰

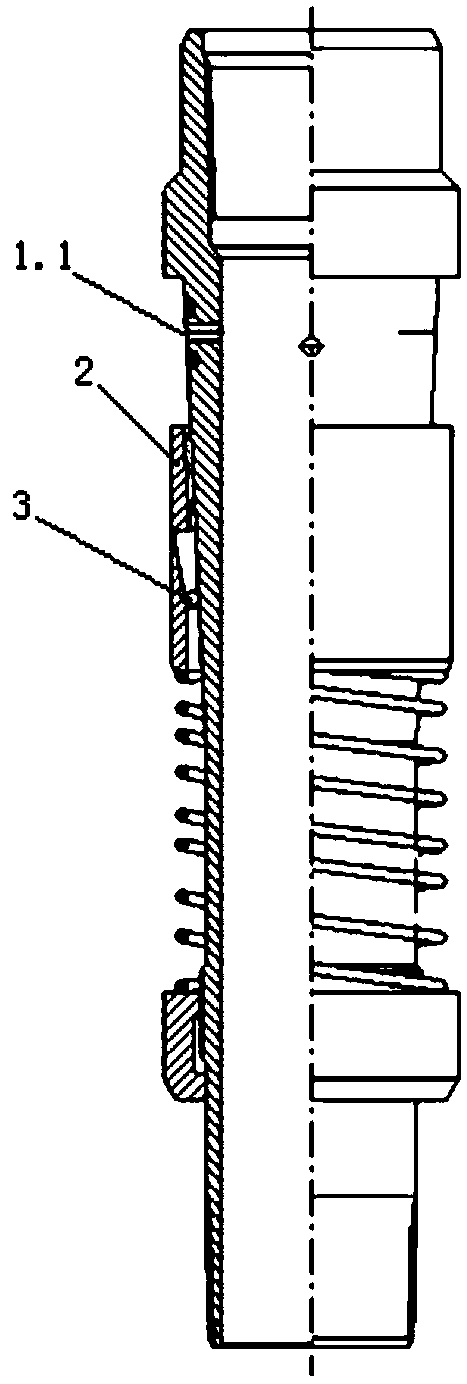

Controllable oil drain device

PendingCN108678708ANo change of pathNo change in intensityWell/borehole valve arrangementsSealing/packingNon magneticUltimate tensile strength

The invention provides a controllable oil drain device. The controllable oil drain device comprises a main body prepared from a non-magnetic material, wherein a seal sleeve, a spring and a regulatingring are arranged on the main body sequentially; a discharge hole in the outer bevel of the main body is sealed by the inner bevel of the seal sleeve, and the spring is arranged between the regulatingring and the seal sleeve; a lock ball is arranged in a lock ball groove in the seal sleeve. The controllable oil drain device has the beneficial effects that inner drift diameter of a tubing string is not changed, clearance volume is not increased, strength of the tubing string is not changed, the oil drain device can be opened only by feeding a strongly magnetic weight bar into the tube string,and the oil drain device is opened reliably.

Owner:TOP WELL PETROLEUM TECH COMPANY

Preparation method of continuous phenolic-foam-filled honeycomb material with fixed height and thickness

ActiveCN105542386AThermal insulationNo change in fire resistancePretreated surfacesCoatingsSurface layerFoaming agent

The invention relates to a preparation method of a continuous phenolic-foam-filled honeycomb material with fixed height and thickness. The preparation method comprises the following steps: (1) preparing a phenolic resin glue liquid uniformly mixing high-performance phenolic resin, a foaming agent, an additive and a curing agent in a weight ratio of 100 to (10-50) to (10-50) to (20-40); (2) gumming: uniformly coating a surface layer of a honeycomb material with the phenolic resin glue liquid by virtue of a gumming device; and (3) curing: sending the honeycomb material coated with the phenolic resin glue liquid into a drying oven, and curing and forming, so as to obtain the phenolic-foam-filled honeycomb material. Compared with the prior art, the honeycomb material prepared by virtue of the preparation method has the advantages that the thermal insulation performance is good, the application range is relatively wide, meanwhile, the continuous production is realized, and the production cost is lowered as much as possible when the quality is guaranteed.

Owner:安徽复材科技有限公司

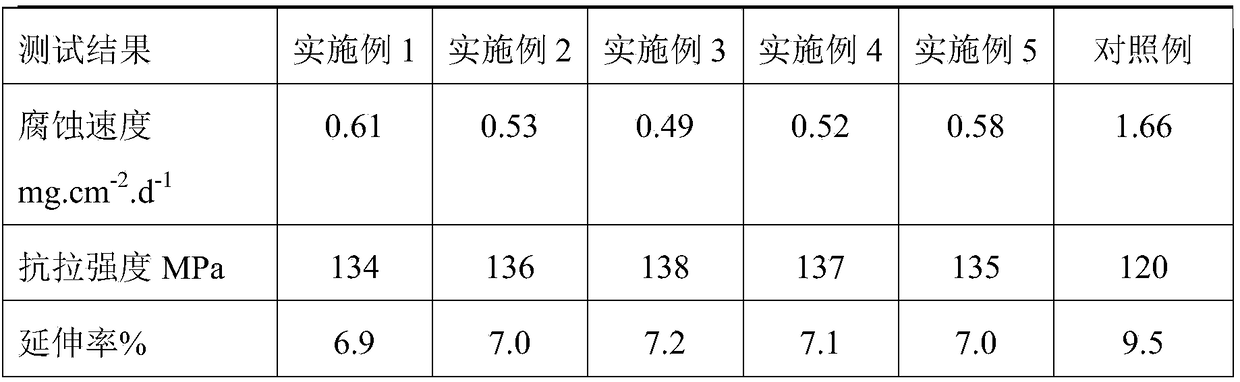

Corrosion-resistant metal material

The invention relates to the field of metal alloy materials, in particular to a corrosion-resistant metal material. The metal material comprises, by weight, 2-5% of Al, 5-8% of C, 4-6% of Si, 1.0-1.5%of Mn, 3-6% of Mg, 2-5% of Cr, 0.15-0.25% of B, 0.01-0.03% of Zr, 0.03-0.05% of Nb and the balance Fe. During production, metals other than Fe, Zr and Nb are preheated and poured into a converter, after molten iron is added for smelting, Zr and Nb are added for refining, and after refining is completed, still standing, inoculation and casting forming are conducted. Iron is the main component of the material, as for other components, carbon is used for improving the strength and toughness of the material, silicon is used for deoxidation, manganese is used for improving the toughness of the material, zirconium and niobium are used for improving the corrosion resistance and strength of the material, through combination of various metal elements, the electrical conductivity, thermal conductivity and strength of the material are improved, the quenching property of the material is reduced, and the material is excellent in oxidation resistance, corrosion resistance, mechanical property and mechanical performance.

Owner:四川大阳实业发展有限公司

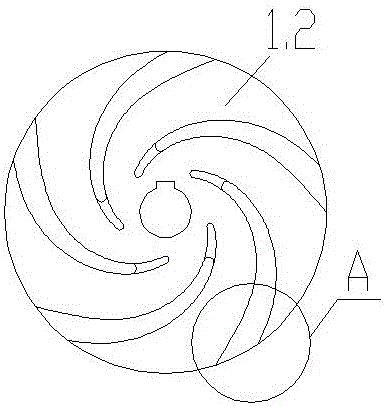

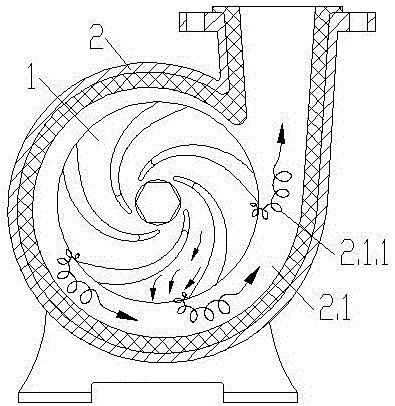

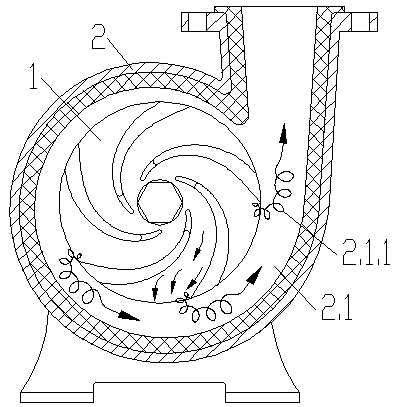

Plastic centrifugal pump

ActiveCN106402017ANo change in thicknessNo change in intensityPump componentsPumpsReverse currentEngineering

The invention discloses a plastic centrifugal pump. The plastic centrifugal pump comprises a pump shell, a main shaft, a shaft seal on the main shaft, a bearing base, and an impeller mounted at the end part of the main shaft and positioned in a volute cavity of the pump shell; the impeller includes an impeller spoke plate, and an impeller blade on the impeller spoke plate; and the inner bending side incision of the tail part of the impeller blade is provided with an inclined guide angle for increasing the flowing angle of a fluid thrown out from a liquid outlet of an impeller runner to forwards flow the fluid in the direction of the liquid outlet of the impeller runner. The thickness and the intensity of the plastic impeller blade are not changed, and the form of the tail part of the impeller blade is only changed, so that the moving direction of the fluid is changed, the generation or / and increment of an eddy current area, a reverse current area and a slow flowing area in a pump cavity is reduced, the convection impact of the fluid is reduced, and the efficiency of the pump is promoted.

Owner:宜兴市宙斯泵业有限公司

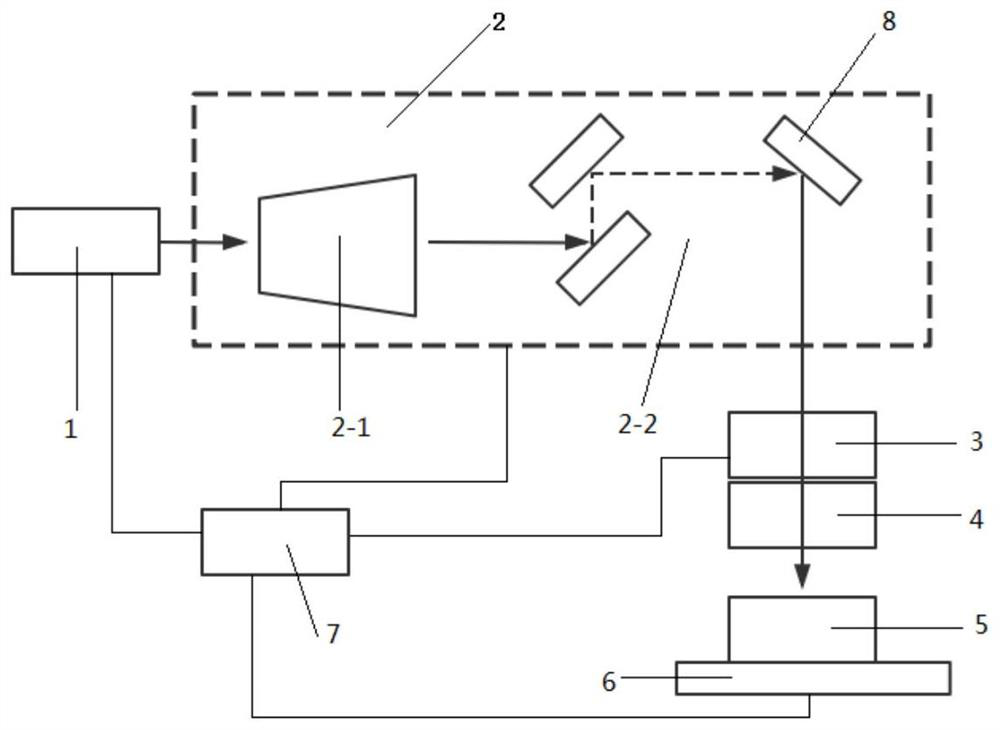

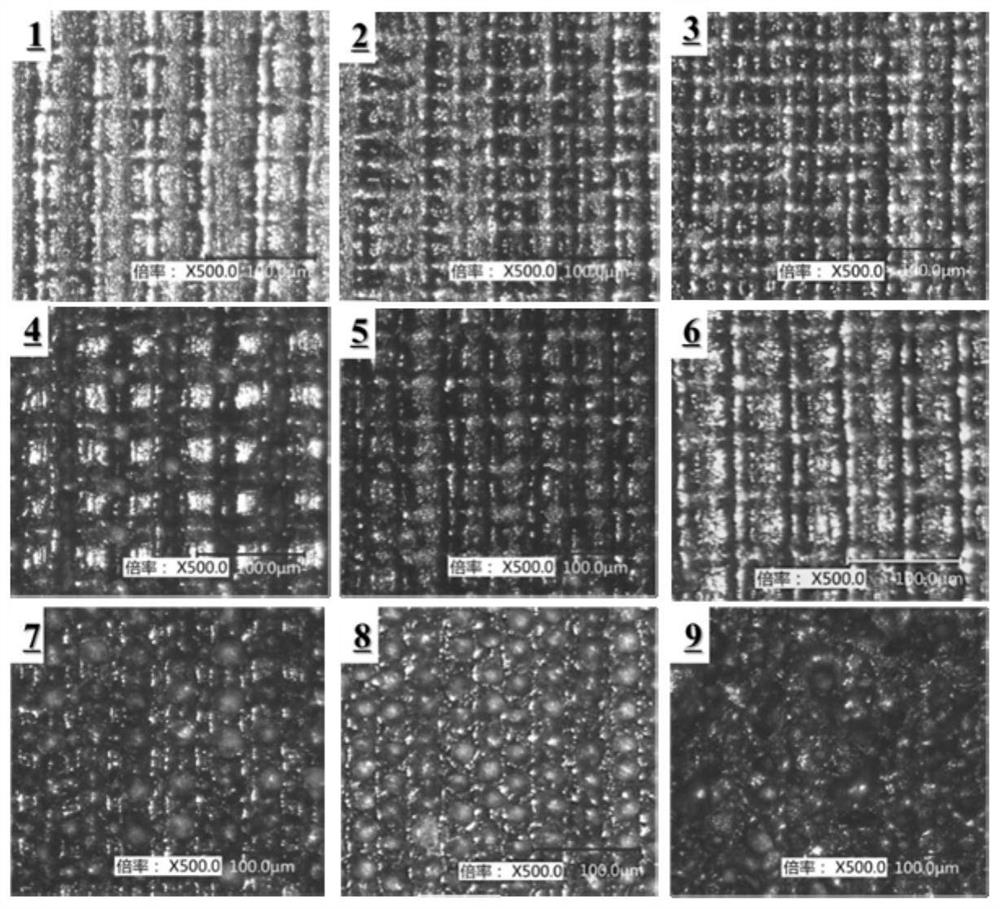

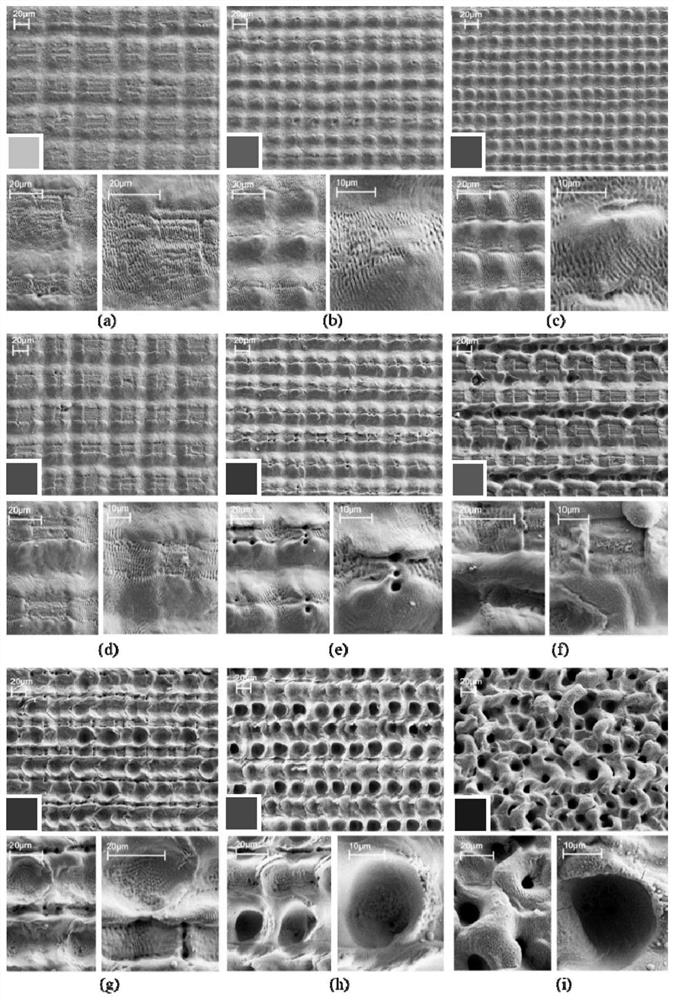

Ultrafast laser precise engraving method and system for leather

PendingCN114273786ANeat processing surfaceMark content is fine and clearLaser beam welding apparatusGalvanometerErbium lasers

The invention provides an ultrafast laser precision engraving method and system for leather, and the method comprises the steps: 1) setting an ultrafast laser which can emit high-energy monopulse at high repetition frequency and has high monopulse energy consistency, the frequency being 1 KHz to 1 MHz, and the monopulse energy being 2-2000 uJ; 2) locking the transmitting frequency as a fixed value; (3) the laser wavelength is set to be 1064 + / -5 nm or 532 + / -5 nm; 4) inputting the ultrafast laser into a galvanometer through a shaping light path and a light beam transmission light path, and focusing the ultrafast laser on leather after passing through a field lens; and (5) precise engraving of the leather is completed under the control of the software and hardware controller. The precise engraving method of the leather is realized through an ultrafast laser vaporization material processing surface with high monopulse energy, almost no heat affected zone appears, the mark content is fine and clear, burn, hot and cold processing are avoided, and no harmful gas is released like silk-screen.

Owner:北京赢圣科技有限公司

Compressor impeller machining method

The invention relates to a compressor impeller machining method, which comprises the steps of: A, preparing a metal alloy material according to a designed proportion for blanking and smelting, pouringby using a mold, turning the position of an inlet ring, and demolding to obtain an impeller blank; B, subjecting the impeller blank to heat treatment, heating the impeller to the quenching temperature, then subjecting weld joints to coping, smooth transition and coloring inspection to check whether defects exist in the weld joints or not and carry out repair welding, tempering after welding to eliminate welding stress, and finally discharging the impeller from the furnace for air cooling; C, correcting a position of the impeller after machining and finish turning by means of a rotating machine; D, and subjecting the surface to roughening treatment, and carrying out surface activating treatment; and E, and thermally spraying a wear-resistant coating on the surface of the impeller in the step D. According to the compressor impeller machining method, the overall strength is not changed, the loss of raw materials is greatly reduced by adopting the new process, the machining difficulty isreduced, the machining efficiency is improved, and the cost is saved.

Owner:常州市庆中风机制造有限公司

Self-drilling anchor rod

ActiveCN113187532ANo change in intensityRealize the function of drillingAnchoring boltsEngineeringMachine

The invention discloses a self-drilling anchor rod. The self-drilling anchor rod comprises a rod body, a limiting nut and a driving nut, the rod body is provided with a first end and a second end, external threads are arranged on the peripheral face of the rod body, the limiting nut is in threaded fit with the rod body, the driving nut is in threaded fit with the rod body, when the driving nut rotates in the first direction, the first face of the driving nut abuts against the second face of the limiting nut, and the rotating torque applied to the limiting nut by the driving nut is smaller than the rotating torque needed by the limiting nut rotating relative to the rod body, therefore, the limiting nut limits the driving nut to move towards the first end of the rod body, and the driving nut drives the rod body to rotate in the first direction. The self-drilling type anchor rod has the advantages of being easy to operate, easy to machine and popularize, high in reliability and high in production efficiency.

Owner:CCTEG COAL MINING RES INST +1

Processing technology of novel ecological environment-friendly cotton swab

PendingCN109758303AThe processing technology and the preparation process are simpleSimple preparation processSwabsTamponsFiberEcological environment

The invention discloses a processing technology of a novel ecological environment-friendly cotton swab. The processing technology of the novel ecological environment-friendly cotton swab comprises thefollowing steps: forming an opening with the depth of 3-5 mm centrally at one end of a swab stick through cutting, then inserting cotton wool into the opening, wrapping the cotton wool around the opening of the cotton swab stick by taking the opening as the center, and finally condensing the cotton wool at the tail end of the cotton wool far away from the opening of the cotton swab stick by rapidburning of flame, wherein the cotton wool is absorbent cotton. The novel ecological environment-friendly cotton swab has the advantages of simple preparation process, low production cost, no generation of substances harmful to the environment basically in the production process, environmental protection and safety; meanwhile, the absorbent cotton obtained by the processing method has good water absorption and water retention effects, and the strength and fineness of the cotton fiber before and after degreasing are basically unchanged.

Owner:思拓科(上海)生物科技股份有限公司

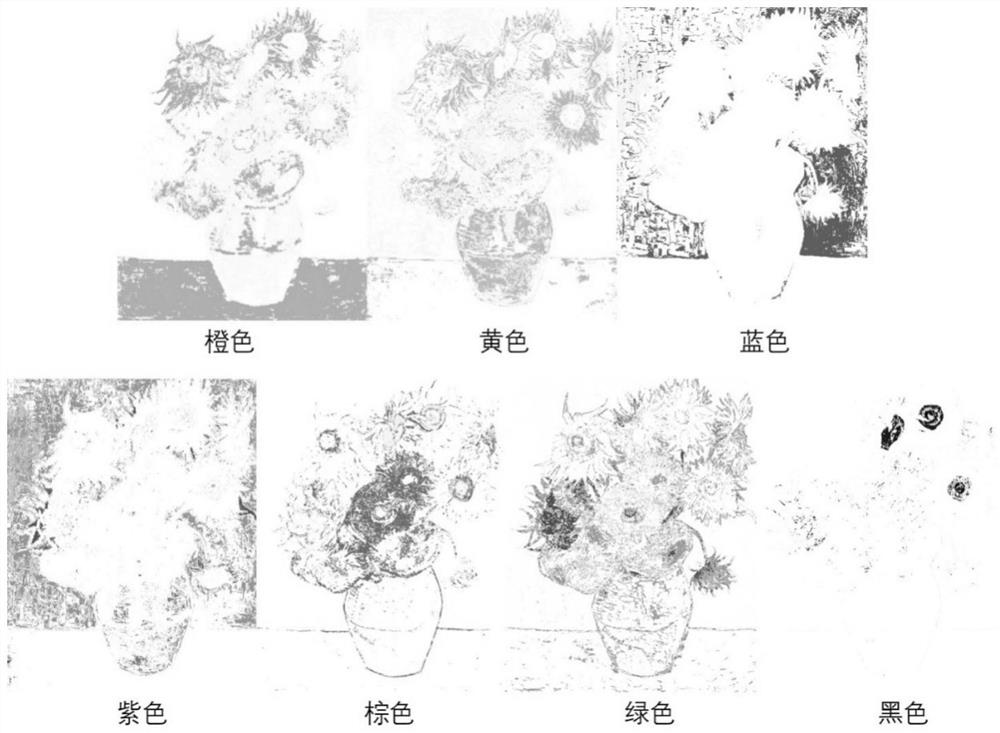

Precise and efficient colored titanium alloy preparation method adopting laser processing

PendingCN113953691APlay a role in surface oxidationIncrease productivityWelding/soldering/cutting articlesLaser beam welding apparatusPicosecond laserFemto second laser

The invention discloses a precise and efficient colored titanium alloy preparation method adopting laser processing, belongs to the field of colored titanium alloy laser processing, and aims to overcome the defects that in an existing titanium alloy surface coloring technology, the surface type and the area of a processed object are limited, a coating is prone to falling off during coloring, the oxidation process is complex, the nanometer photoetching efficiency is low, and the cost is high. The method comprises the following steps: cleaning and airing a titanium alloy, and then placing the titanium alloy on a processing table of an infrared picosecond laser; using ezCAD software capable of controlling a scanning galvanometer to work for selecting laser parameters and machining process parameters according to the surface coloring requirement; performing laser coloring; and performing cleaning again and airing. The heat effect of picosecond laser processing is far lower than that of nanosecond laser processing, and damage to materials is small; the cost is lower than that of femtosecond laser processing and the efficiency is higher; the method has no special requirements on the environment, is simple and can easily achieve automatic processing; the size of the processed object is unlimited; a product with a complex structure can be colored by matching with a processing platform; and material surface pretreatment is simple, green and environment-friendly.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

A plastic centrifugal pump

ActiveCN106402017BNo change in thicknessNo change in intensityPump componentsPumpsReverse currentEngineering

The invention discloses a plastic centrifugal pump. The plastic centrifugal pump comprises a pump shell, a main shaft, a shaft seal on the main shaft, a bearing base, and an impeller mounted at the end part of the main shaft and positioned in a volute cavity of the pump shell; the impeller includes an impeller spoke plate, and an impeller blade on the impeller spoke plate; and the inner bending side incision of the tail part of the impeller blade is provided with an inclined guide angle for increasing the flowing angle of a fluid thrown out from a liquid outlet of an impeller runner to forwards flow the fluid in the direction of the liquid outlet of the impeller runner. The thickness and the intensity of the plastic impeller blade are not changed, and the form of the tail part of the impeller blade is only changed, so that the moving direction of the fluid is changed, the generation or / and increment of an eddy current area, a reverse current area and a slow flowing area in a pump cavity is reduced, the convection impact of the fluid is reduced, and the efficiency of the pump is promoted.

Owner:宜兴市宙斯泵业有限公司

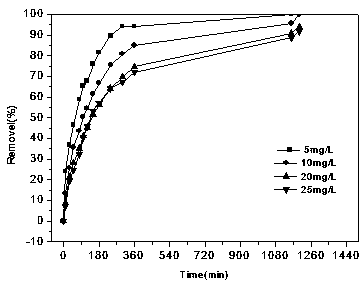

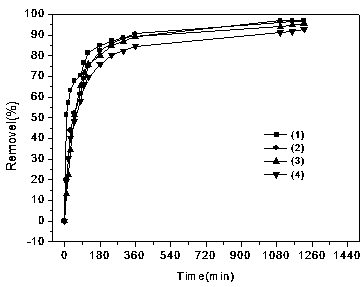

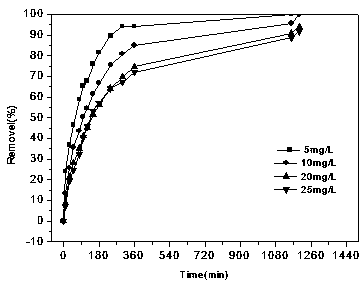

A kind of magnetic adsorbent containing chitosan quaternary ammonium salt and preparation method thereof

InactiveCN106423080BEasy to fixImprove hydrophilic abilityOther chemical processesSpecific water treatment objectivesCrosslinked chitosanSorbent

The invention provides a magnetic adsorbent containing chitosan quaternary ammonium salt and a preparation method. The magnetic adsorbent is a porous magnetic composite material comprising crosslinked chitosan quaternary ammonium salt (3-40wt%), ferriferrous oxide (5-30wt%) and polymers (92-30wt%). The method is carried out according to the following steps: 1, preparation of polymer suspension; 2, preparation of the magnetic adsorbent. The magnetic adsorbent containing chitosan quaternary ammonium salt disclosed by the invention has high mechanical strength, large granules and easy solid-liquid separation, the density of the magnetic adsorbent can be adjusted by the content ratio of polymers and ferriferrous oxide, the strength and the adsorption property of a post-regeneration adsorbent are not changed basically, and the magnetic adsorbent can be recycled and can be directly added into water bodies or filled in an adsorption column or an adsorption tower for adsorbing anions in the water bodies.

Owner:HUBEI UNIV OF TECH

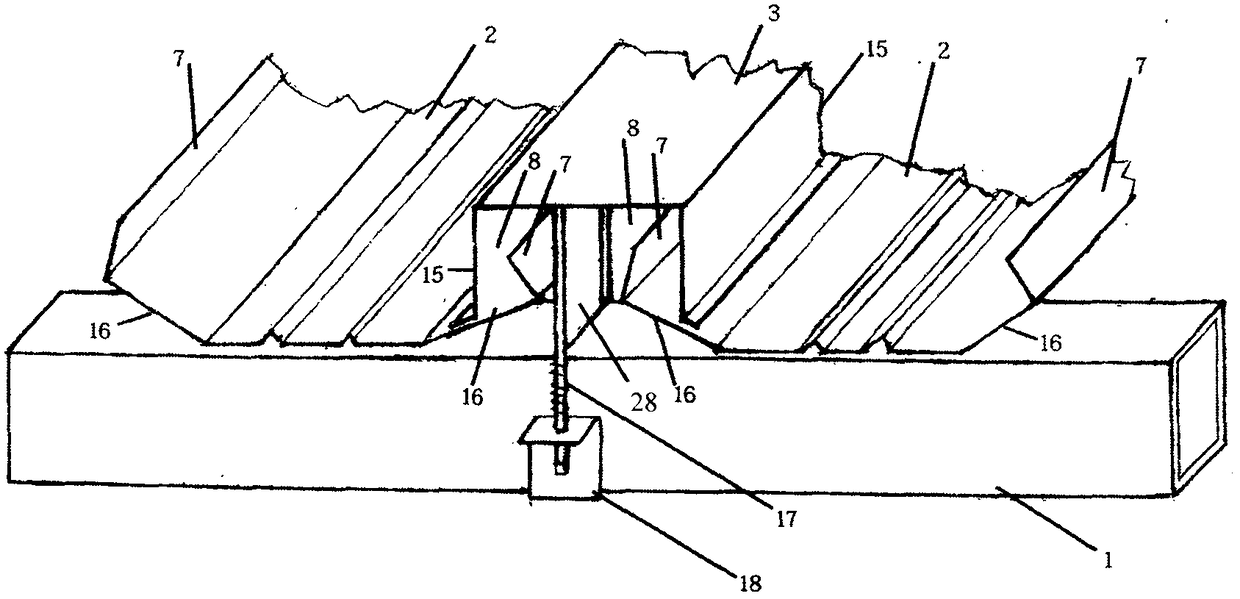

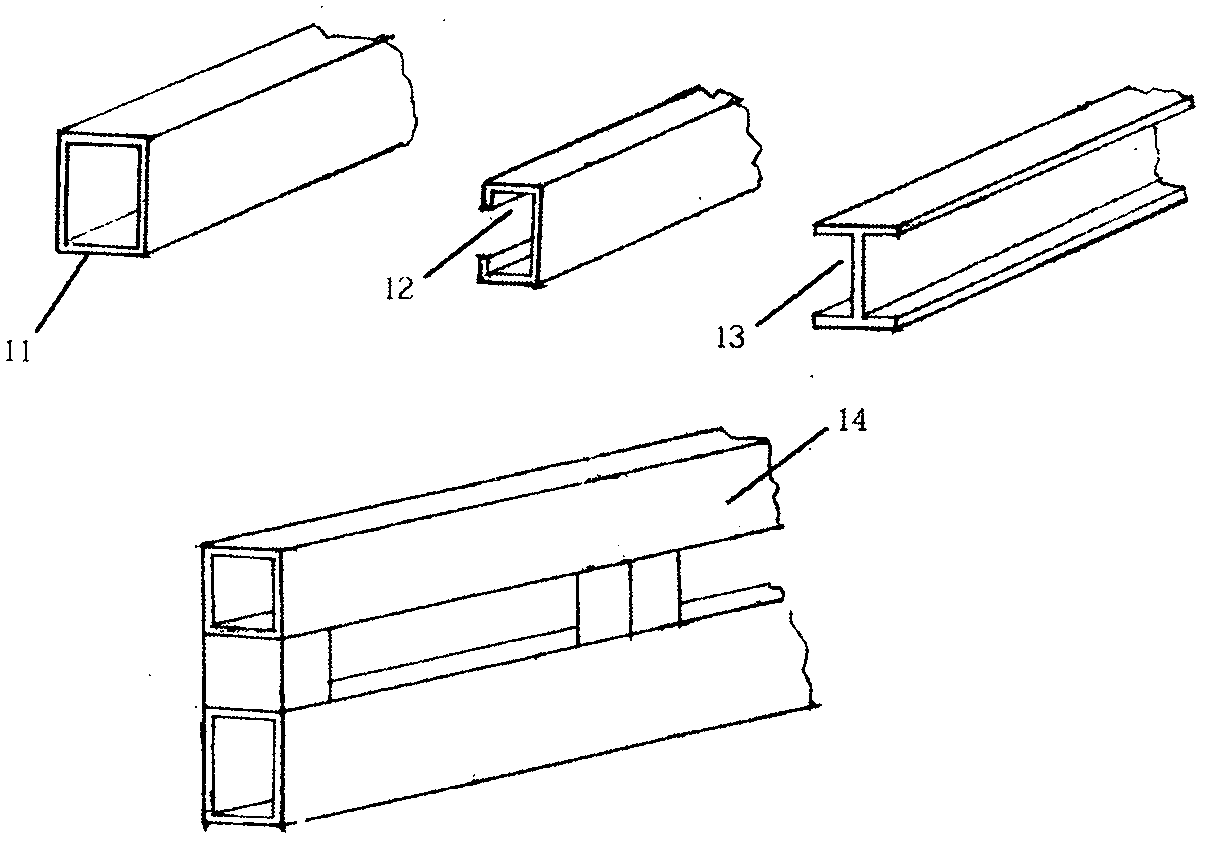

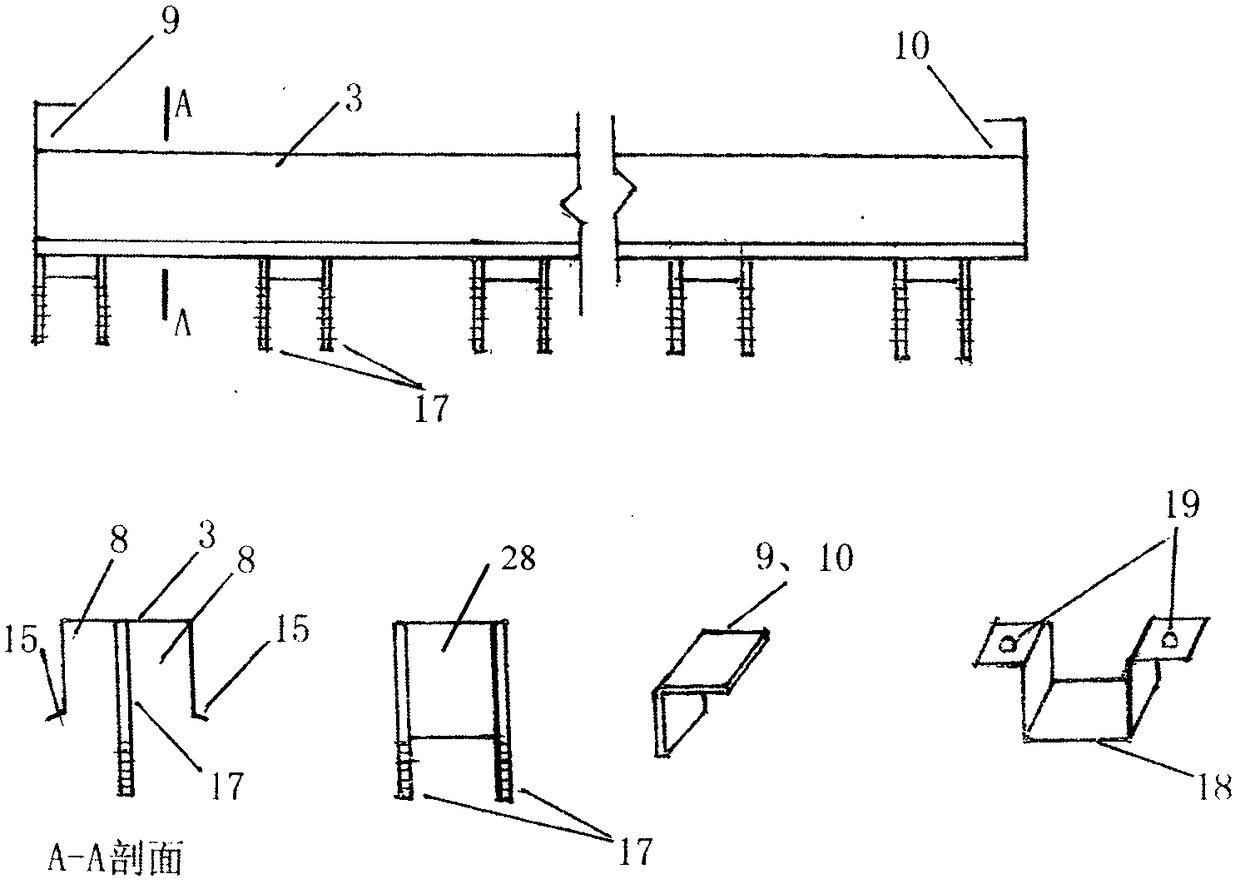

An internally fixed metal and plastic roofing system that can be installed, disassembled, moved, and reinstalled

ActiveCN106121136BNo pollution in the processNo change in intensityRoof covering using slabs/sheetsMetallic materialsCornice

An internal fixing type metal and plastic roof system capable of being mounted, dismounted, moved and reinstalled comprises roof purlines, prismatic groove roof plates, roof plate pressing cover strips, ridge pressing cover strips, roof plate slope top end sealing rubber pressing strips and roof plate cornice pressing strips, wherein the prismatic groove roof plates are arranged on the roof purlines; each roof plate pressing cover strip covers the seam between every two prismatic groove roof plates; the roof indoor sides of the roof plate pressing cover strips are connected and fastened to the roof purlines through internally fixed connecting points; and the roof indoor sides of the ridge pressing cover strips are also connected and fastened to the purlines at the ridge through internally fixed connecting points. Members forming the roof system are made of metal materials or non-metal materials with enough strength, designed according to standards, machined and manufactured in a factory and installed on site. Connecting joints between the members are simple, and easy to manufacture, and the roof system is easy to mount, dismount and reinstall. The members are reusable, and the engineering manufacturing cost is lowered.

Owner:林娟

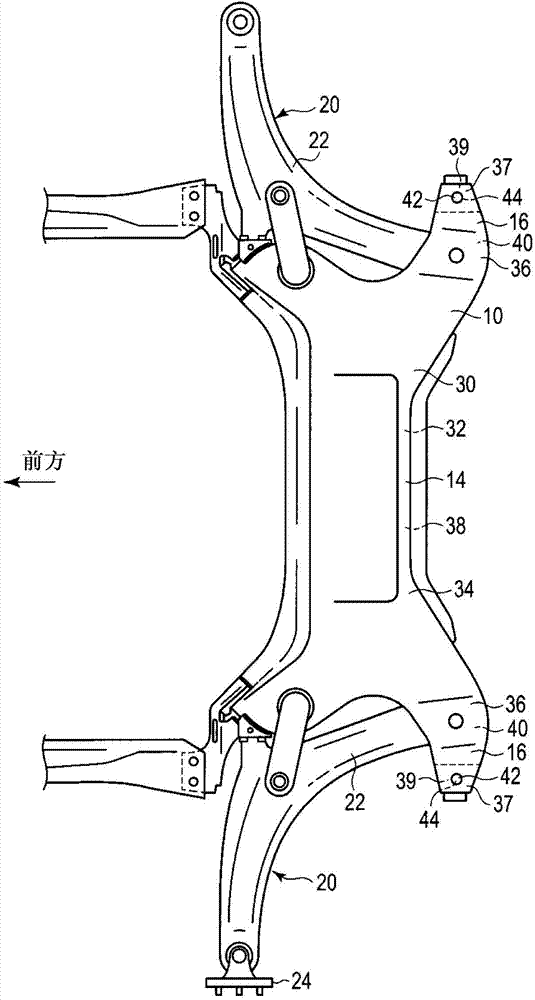

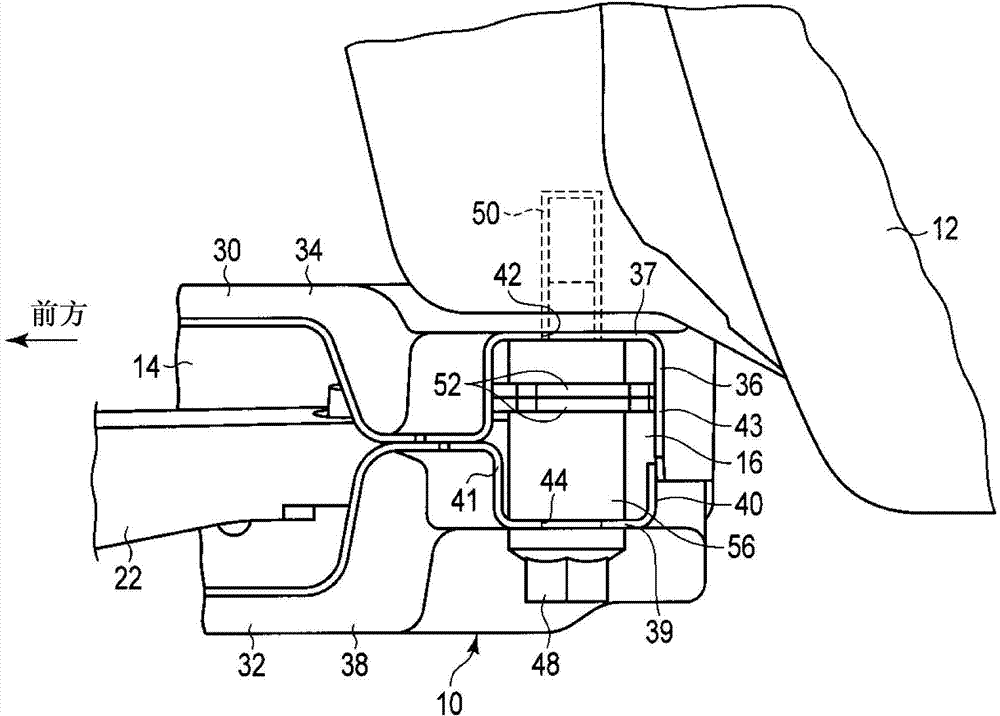

Cross member

ActiveCN103770846AAdjustment off loadDoes not change rigiditySuperstructure subunitsEngineeringMechanical engineering

Owner:MITSUBISHI MOTORS CORP

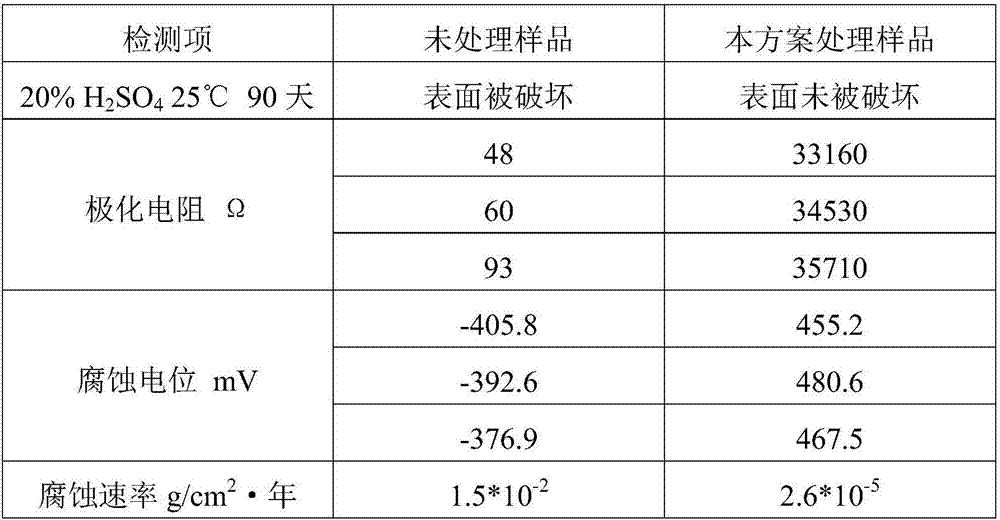

Corrosion resistant treatment technology of austenitic stainless steel

ActiveCN107419276ANo pollution in the processSimple processing methodTherapeutic effectUltimate tensile strength

The invention relates to a corrosion resistant treatment technology of austenitic stainless steel. The corrosion resistant treatment technology of the austenitic stainless steel comprises the following steps that (1), rust removing, washing and dry wiping are conducted on the surface of an austenitic stainless steel substrate; (2) the surface of the treated austenitic stainless steel substrate is coated with a cotton material, the cotton material is further coated with a stainless steel screen mesh, and polarized power lines are clamped at the two ends of the stainless steel screen mesh; and (3) an electrolyte solution is dripped into the cotton material to enable the cotton material to be wet, electric polarization treatment, washing and dry wiping are conducted, and thus the corrosion resistant treatment of the austenitic stainless steel is completed. Compared with the prior art, the treatment technology is good in corrosion resistant treatment effect, generates no pollution on the environment, and is simple and practicable, does not change original properties, such as strength, electrical conductivity and thermal conductivity, of the substrate, is short in treatment time, and the like.

Owner:SHANGHAI JIANYE TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com