Ultrafast laser precise engraving method and system for leather

An ultra-fast laser and precision technology, applied in the field of leather ultra-fast laser precision engraving method and system, can solve the problems of releasing toxic gas, poor heat dissipation, leather burning, etc., and achieve fast processing time and fine and clear marking content , The effect of neat processing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

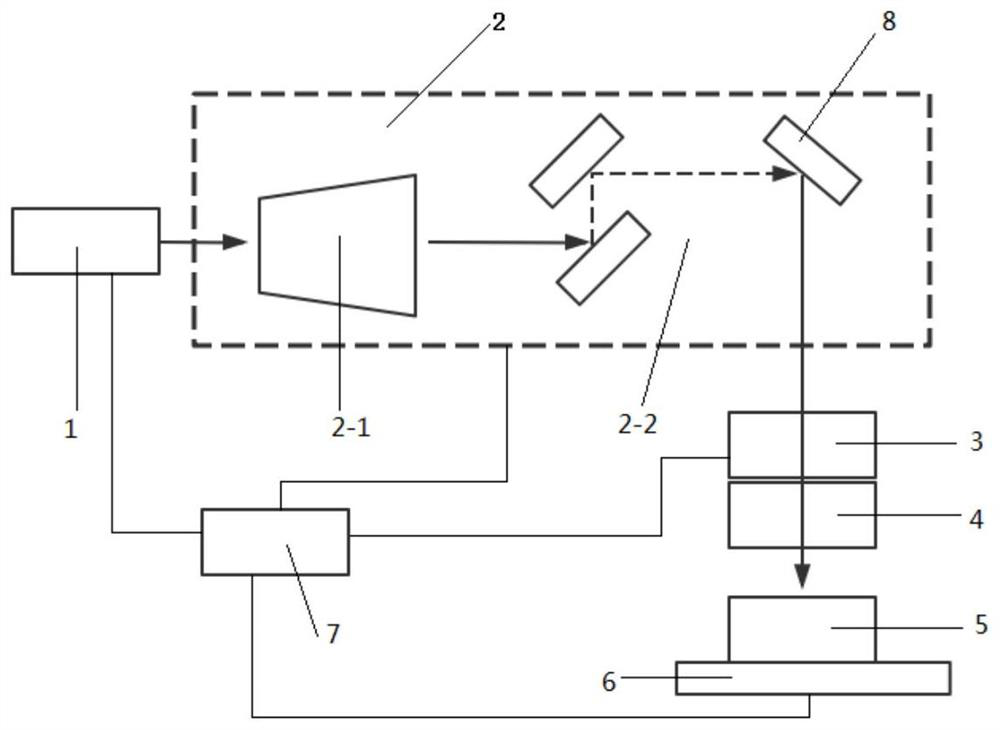

[0063] Connect the laser through the data cable to a computer mounted with a laser precision engraving system software, the computer inputs the controlled laser power, the scan speed, and the repetition frequency signal to the laser, and the laser is a full solid picosecond laser. The controller receives the pulse synchronization signal of the laser, and controls the optical path, gasel, field mirror, and continuous engraving platform to complete precision engraving.

[0064] The laser wavelength is 355 ± 5 nm.

[0065] The locking emission frequency is 500 kHz; single pulse energy is 4UJ. The single pulse width is 10ps.

[0066] The laser window spot is 2mm, the divergent angle is 1.0mRAD.

[0067] The plastic circuit is a beam optical path of 5 times the magnification.

[0068] The beam transport optical path consists of a transmission optical path of the transmission distance of 500 mm.

[0069] The mirror speed is 1000 rpm.

[0070] Field glasses are F-θ field glasses, the foc...

Embodiment 2

[0078] The same is basically the same as in Example 2, and the situation is in that

[0079] The laser wavelength is 1064 ± 5 nm.

[0080] The locking emission frequency is 1 kHz; single pulse energy is 500uj. The single pulse width is 1PS.

[0081] The laser window spot is 3 mm, the divergent angle is 0.5mRAD.

[0082] The plastic optical path is a retroff of a magnification of 1 times.

[0083] The beam transport optical path consists of a transmission optical path of the transmission distance 10 mm.

[0084] The mirror speed is 10,000 rpm.

[0085] Field glasses are F-θ field glasses, the focal length is 500mm.

[0086] The minimum resolution feature size of the microstructure of the precision engraving pattern is 10 um.

[0087] The leather is precisely engraved using the above laser:

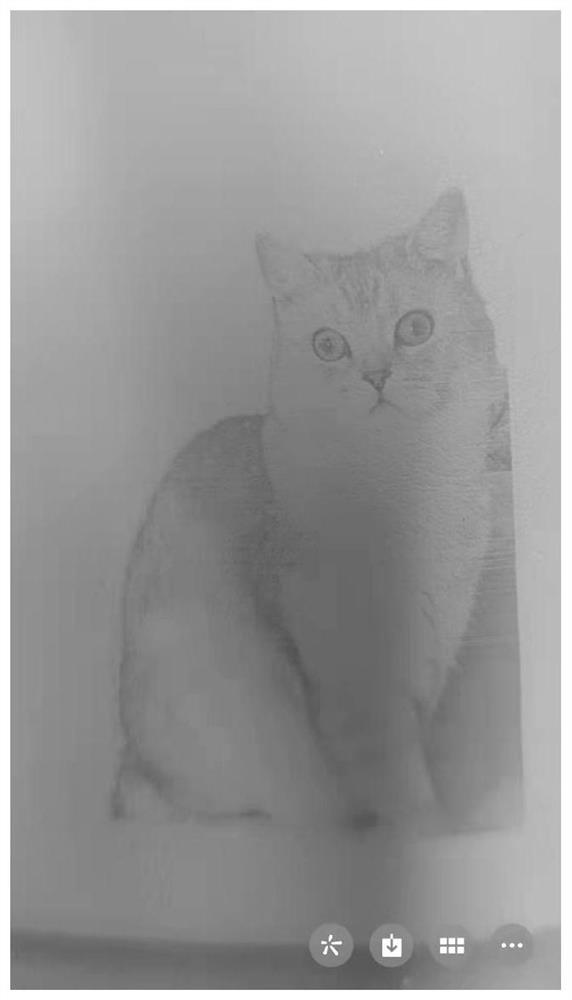

[0088] Precision engraving effect image 3 Indicated.

Embodiment 3

[0090] The same is basically the same as in Example 2, and the situation is in that

[0091] The laser wavelength is 532 ± 5 nm.

[0092] The locking emission frequency is 1 MHz; single pulse energy is 10UJ. The single pulse width is 5ps.

[0093] The laser window spot is 1 mm, the divergent angle is 1.5mRAD.

[0094] The plastic optical path is an enlarged optical path of 8 times the magnification.

[0095] The beam transport optical path consists of a transmission optical path of the transmission distance of 1000 mm.

[0096] The mirror working speed is 100 rpm.

[0097] Field glasses are distant mirrors, the focal length is 50mm.

[0098] The minimum resolution characteristic size of the microstructure forming the precision engraving pattern is 0.5um.

[0099] The leather was precisely engraved using the above laser.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Divergence angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com