Electro-thermic working tool used for evanescent casting model

A processing tool and disappearing casting technology, which is applied in the field of electrothermal processing tools, can solve the problems of affecting appearance and product grade, poor surface quality of cast iron parts, poor processing surface quality, etc., and achieve light structure, low manufacturing cost and neat processing surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

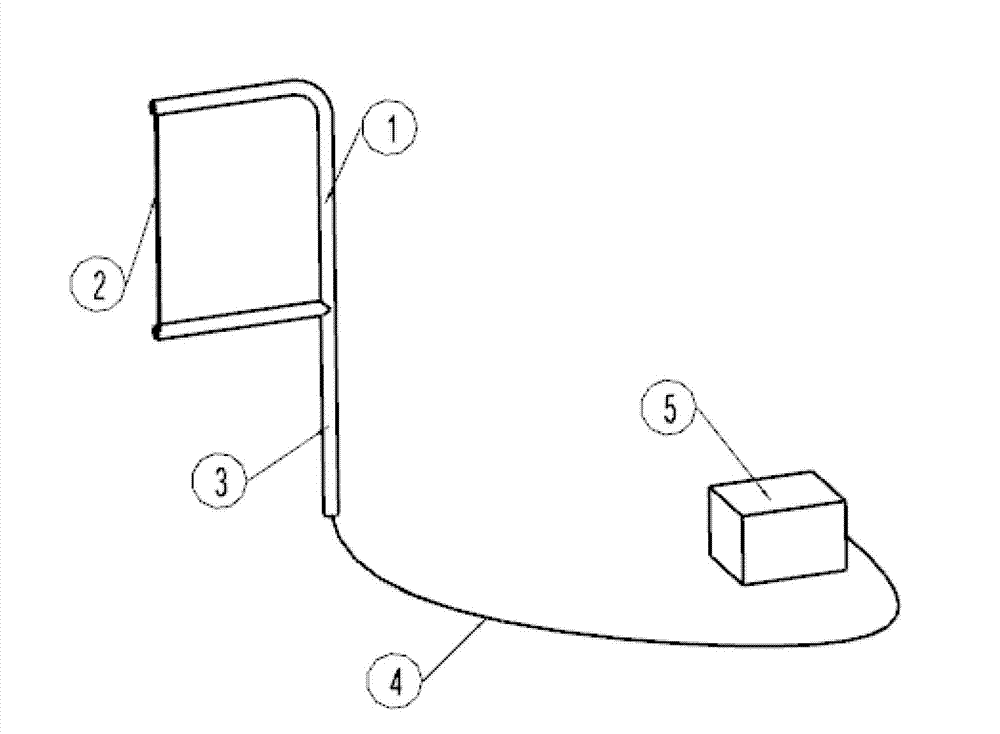

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, an electrothermal processing tool for a lost casting model includes a tool body 1, a resistance wire 2 and a transformer 5. The workpiece body is in an "F" shape, and the long side of the tool body is used as a handle 3. The tool body The body is made of insulating material; the two ends of the resistance wire are respectively connected to the two short side ends of the workpiece body, and the resistance wire is connected to the transformer through a wire 4 . In order to be neat and tidy, the inside of the tool body is hollow, and the wire passes through the inside of the tool body to connect with the resistance wire. In order to be able to control the temperature of the resistance wire, the transformer adopts an adjustable transformer.

[0012] When in use, first adjust the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com