Corrosion-resistant metal material

A metal material and corrosion-resistant technology, applied in the field of metal alloy materials, can solve the problems of chemical composition change, corrosion speed acceleration, corrosion resistance limitation, etc., and achieve the effect of increasing yield strength, increasing corrosion resistance, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

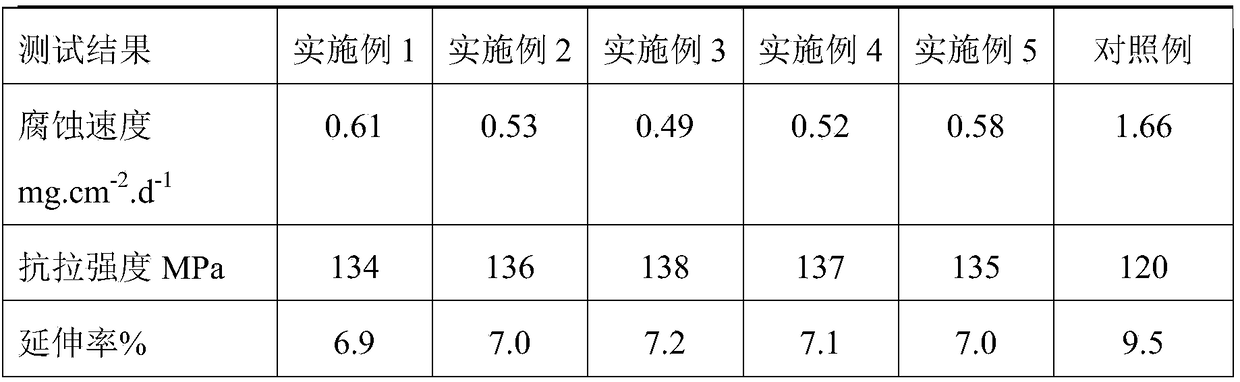

Examples

Embodiment 1

[0022] This embodiment provides a corrosion-resistant metal material, which includes the following chemical components and the weight percentages of each chemical component are: Al 2%, C 5%, Si 4%, Mn 1.0%, Mg 3%, Cr 2%, B 0.15%, Zr 0.01%, Nb 0.03%, and the rest is Fe.

[0023] A kind of corrosion-resistant metal material that this example realizes comprises the following steps:

[0024] Step 1. Preheating: weigh other metals except Fe, Zr, and Nb according to the weight ratio, preheat to 300-350°C and put them into the converter;

[0025] Step 2. Smelting: Weigh Fe according to the weight ratio, melt it into molten iron, pour it into a converter, and smelt the metal material in the furnace. The melting atmosphere is an oxygen atmosphere, that is, using an oxygen top-blown converter for smelting. The time is 30min, the oxygen blowing time is 20min, and stir evenly after smelting;

[0026] Step 3. Refining: Weigh Zr and Nb according to the weight ratio, add the melt obtained ...

Embodiment 2

[0029] This embodiment provides a corrosion-resistant metal material, which includes the following chemical components and the weight percentages of each chemical component are: Al 3%, C 6%, Si 5%, Mn 1.1%, Mg 5%, Cr 3%, B 0.18%, Zr 0.02%, Nb 0.04%, and the rest is Fe.

[0030] A kind of corrosion-resistant metal material that this example realizes comprises the following steps:

[0031] Step 1. Preheating: weigh other metals except Fe, Zr, and Nb according to the weight ratio, preheat to 350-400°C and put them into the converter;

[0032] Step 2. Smelting: Weigh Fe according to the weight ratio, melt it into molten iron, pour it into a converter, and smelt the metal material in the furnace. The melting atmosphere is an oxygen atmosphere, that is, using an oxygen top-blown converter for smelting. The time is 32min, the oxygen blowing time is 22min, and stir evenly after smelting;

[0033] Step 3. Refining: Weigh Zr and Nb according to the weight ratio, add the melt obtained ...

Embodiment 3

[0036] This embodiment provides a corrosion-resistant metal material, which includes the following chemical components and the weight percentages of each chemical component are: Al 4%, C 7%, Si 6%, Mn 1.2%, Mg 6.5%, Cr 4%, B 0.20%, Zr 0.03%, Nb 0.05%, and the rest is Fe.

[0037] A kind of corrosion-resistant metal material that this example realizes comprises the following steps:

[0038] Step 1. Preheating: weigh other metals except Fe, Zr, and Nb according to the weight ratio, preheat to 400-450°C and put them into the converter;

[0039] Step 2. Smelting: Weigh Fe according to the weight ratio, melt it into molten iron, pour it into a converter, and smelt the metal material in the furnace. The melting atmosphere is an oxygen atmosphere, that is, using an oxygen top-blown converter for smelting. The time is 35 minutes, the oxygen blowing time is 25 minutes, and the mixture is stirred evenly after the smelting is completed;

[0040] Step 3. Refining: Weigh Zr and Nb accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com