A kind of magnetic adsorbent containing chitosan quaternary ammonium salt and preparation method thereof

A technology of chitosan quaternary ammonium salt and magnetic adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve the problems of small particles, unsuitable adsorption columns or adsorption towers, and easy shedding and loss and other problems, to achieve the effect of large particles, easy solid-liquid separation, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of polymer suspension

[0030] Take 14.0mL polyethylene glycol (400) and dissolve it in 110mL N-N dimethylacetamide, add 10.0g ferric oxide and chitosan quaternary ammonium salt cross-linked with different masses (glutaraldehyde is the cross-linking agent), After stirring for 15 minutes, 20.0 g of polyvinylidene fluoride was added to the solution, and dissolved in an electric thermostat oven at 60°C for more than 12 hours to obtain a polymer suspension;

[0031] 2. Preparation of magnetic adsorbent

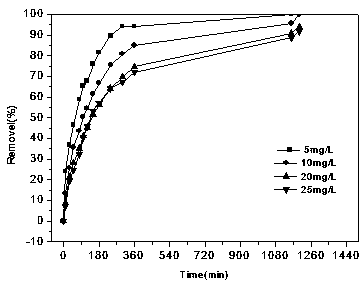

[0032] Use water as the gelling agent, spray the solution into water at room temperature, gel for more than 12 hours, take out the adsorption microspheres (Table 1) that have been dried in an oven to obtain different contents of quaternary ammonium salts, and study their effect on methyl orange. of adsorption.

[0033] Table 1: Content of cross-linked chitosan quaternary ammonium salt microspheres in polyvinylidene fluoride-carrier magnetic adsorbent

[00...

Embodiment 2

[0038] 1. Preparation of polymer suspension

[0039] Dissolve 8.0g of polyvinylpyrrolidone (K30) in 100mL of dimethyl sulfoxide, add 5.0g of ferric oxide and 20.0g of cross-linked chitosan quaternary ammonium salt (epichlorohydrin as the cross-linking agent), and stir for 15 minutes Finally, 26.0 g of polysulfone was added to the solution, and dissolved in a drying oven at 60°C for more than 12 hours to obtain a polymer suspension;

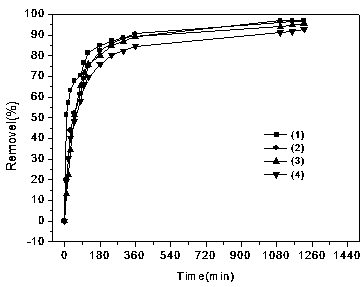

[0040] 2. Preparation of magnetic adsorbent

[0041] Using water as the gelling agent, extrude the solution into a circular strip into water at room temperature, gel for 24 hours, take it out after molding, cut it into pellets, dry it in an oven for later use, and obtain a quaternary substance with a content of 39.2wt%. Ammonium salt adsorption microspheres, the removal effect of some common anions in water (the ratio of the concentration of adsorbed ions to the initial ion concentration) is shown in Table 2 (at 25°C, add 5g of magnetic adsorbent...

Embodiment 3

[0045] 1. Preparation of polymer suspension

[0046] Take 10.0g of polyethylene glycol (600) and dissolve it in 110mL of N-methylpyrrolidone, add 5.0g of ferric oxide and chitosan quaternary ammonium salts crosslinked with different masses (glutaraldehyde is the crosslinking agent), and stir for 15 minutes Finally, 20.0 g of polyvinylidene fluoride was added to the solution, and dissolved in an electric thermostat oven at 60°C for 36 hours to obtain a polymer suspension;

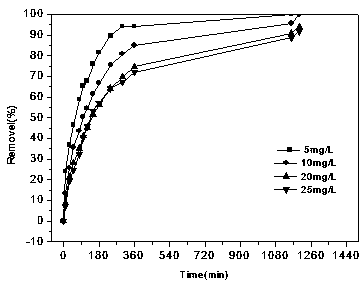

[0047] 2. Preparation of magnetic adsorbent

[0048] The obtained polymer suspension was sprayed into water through a droplet generator, and water was used as a gelling agent to gel at normal temperature and pressure for 48 hours to obtain spherical particles of the magnetic adsorbent. If particles of other shapes are required, they can be extruded into various shapes of magnetic adsorbent particles by extrusion molding, and dried to obtain different shells of magnetic adsorbents containing sodium polystyre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com