Corrosion resistant treatment technology of austenitic stainless steel

A technology for the treatment of austenitic stainless steel, which is applied in the field of corrosion-resistant treatment of austenitic stainless steel, can solve problems such as difficulties, inability to improve the corrosion resistance level of stainless steel, and high cost, and achieve short treatment time, simple and easy process methods, The effect of improving the corrosion resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

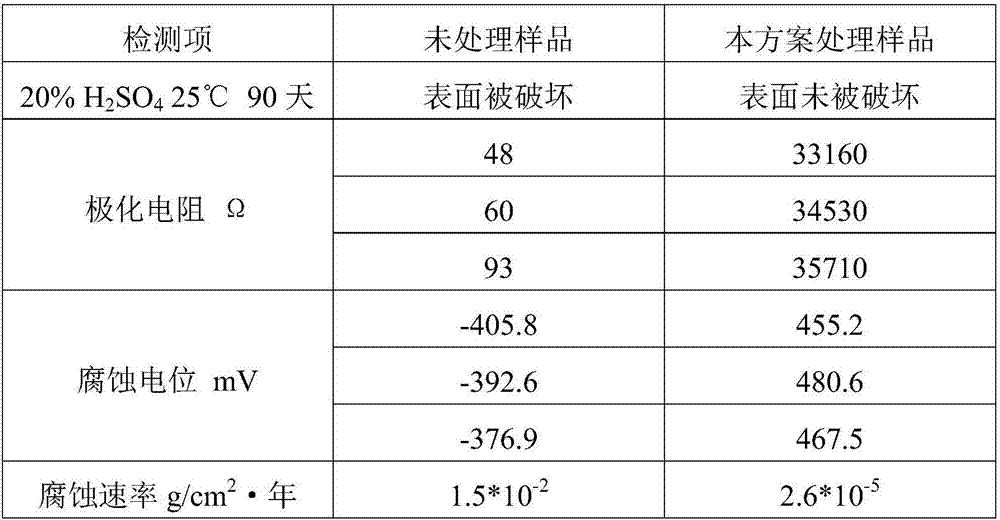

Examples

Embodiment 1

[0025] 304 (DN20) stainless steel pipe corrosion resistance treatment process

[0026] (1) Empty the material in the 304 stainless steel pipe to ensure that there are no flammable and explosive substances. Use manual or mechanical grinding to remove rust on the surface of the stainless steel pipe to meet the requirements of rust removal grade Sa2.5 and roughness Rz30~70vm.

[0027] (2), winding ribbon-shaped cotton material on the stainless steel pipe, the cotton material bound on the steel pipe is closely arranged, and the winding thickness is controlled at 0.5cm;

[0028] (3) The cotton material is wrapped with 60-mesh stainless steel wire mesh, the stainless steel wire mesh fully covers the cotton material, and the length of one electrochemical treatment is controlled at 3m; and the polarized power cord is connected to both ends of the stainless steel wire mesh;

[0029] (4), add nitric acid, the electrolytic solution that sodium nitrate is formed to cotton material, make c...

Embodiment 2

[0037] 304 (DN20) stainless steel pipe corrosion resistance treatment process

[0038] (1) Empty the material in the 304 stainless steel pipe to ensure that there are no flammable and explosive substances. Use manual or mechanical grinding to remove rust on the surface of the stainless steel pipe to meet the requirements of rust removal grade Sa2.5 and roughness Rz30vm.

[0039] (2), winding strip cotton material on the stainless steel pipe, the cotton material bound on the steel pipe is closely arranged, and the winding thickness is controlled at 1cm;

[0040] (3) Cotton material is wrapped with 20-mesh stainless steel wire mesh, the stainless steel wire mesh fully covers the cotton material, and the length of one electrochemical treatment is controlled at 2m; and polarized power lines are connected at both ends of the stainless steel wire mesh;

[0041] (4), add nitric acid, sodium nitrate electrolyte solution to the cotton material, make the cotton material moist, but just ...

Embodiment 3

[0045] 304 (DN20) stainless steel pipe corrosion resistance treatment process

[0046] (1) Empty the material in the 304 stainless steel pipe to ensure that there are no flammable and explosive substances. Use manual or mechanical grinding to remove rust on the surface of the stainless steel pipe to meet the requirements of rust removal grade Sa2.5 and roughness Rz70vm.

[0047] (2), winding ribbon-shaped cotton material on the stainless steel pipe, the cotton material bound on the steel pipe is closely arranged, and the winding thickness is controlled at 0.8cm;

[0048] (3) The cotton material is wrapped with 80-mesh stainless steel wire mesh, the stainless steel wire mesh fully covers the cotton material, and the length of one electrochemical treatment is controlled at 5m; and the polarized power cord is connected to both ends of the stainless steel wire mesh;

[0049] (4), add nitric acid, the electrolytic solution that sodium nitrate is formed to cotton material, make cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com