Patents

Literature

63results about How to "No change in thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

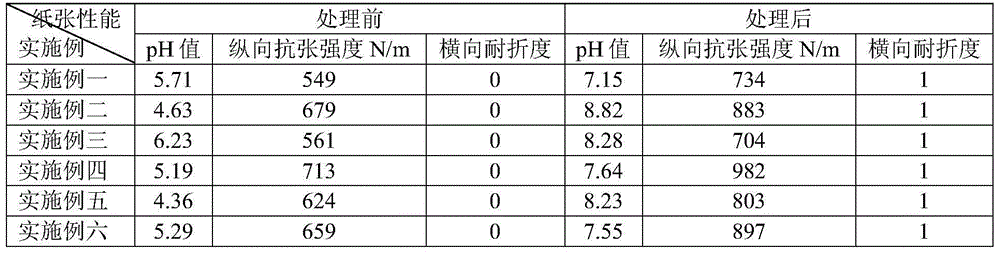

Paper historical relic deacidifying and reinforcing protective material and preparation method thereof

The invention discloses a paper historical relic deacidifying and reinforcing protective material. The paper historical relic deacidifying and reinforcing protective material consists of a solvent and an active component, wherein the active component is a compound formed by chelating a metal ion with starch or hydroxyl contained cellulose. In addition, the invention also discloses a preparation method of the paper historical relic deacidifying and reinforcing protective material. According to the protective material provided by the invention, deacidification and reinforcing treatment are combined, so that the protective material has the excellent comprehensive protective performances of safety, simplicity, convenience, durability, no membrane formation and the like, so that the paper historical relic is deacidified and reinforced once; the operation is simplified, and meanwhile, the obvious and durable reparation effect can be obtained. The preparation method is simple and is beneficial to popularization and application, the cost is low, and the use is safe, simple and convenient.

Owner:广州乾程化工科技发展有限公司

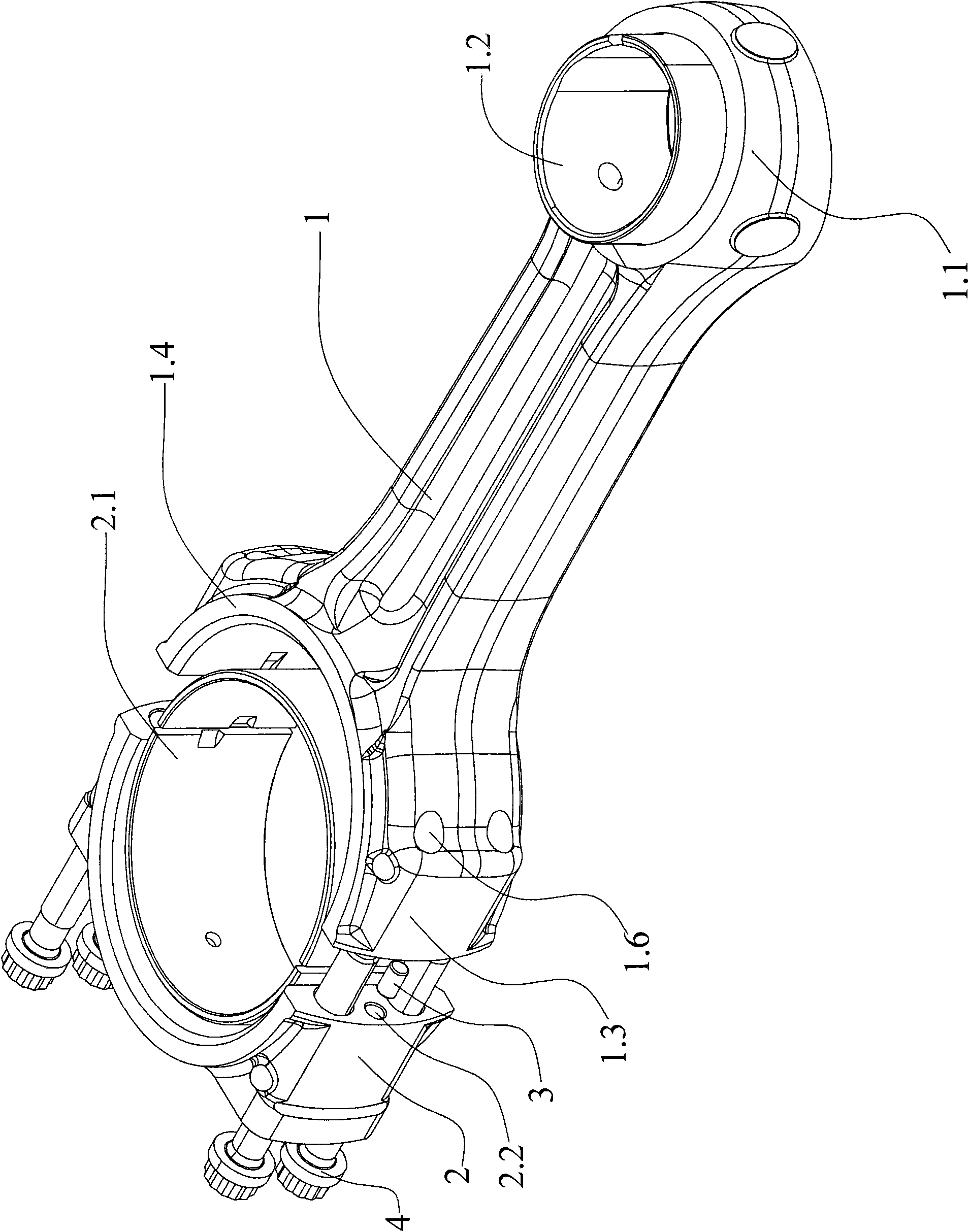

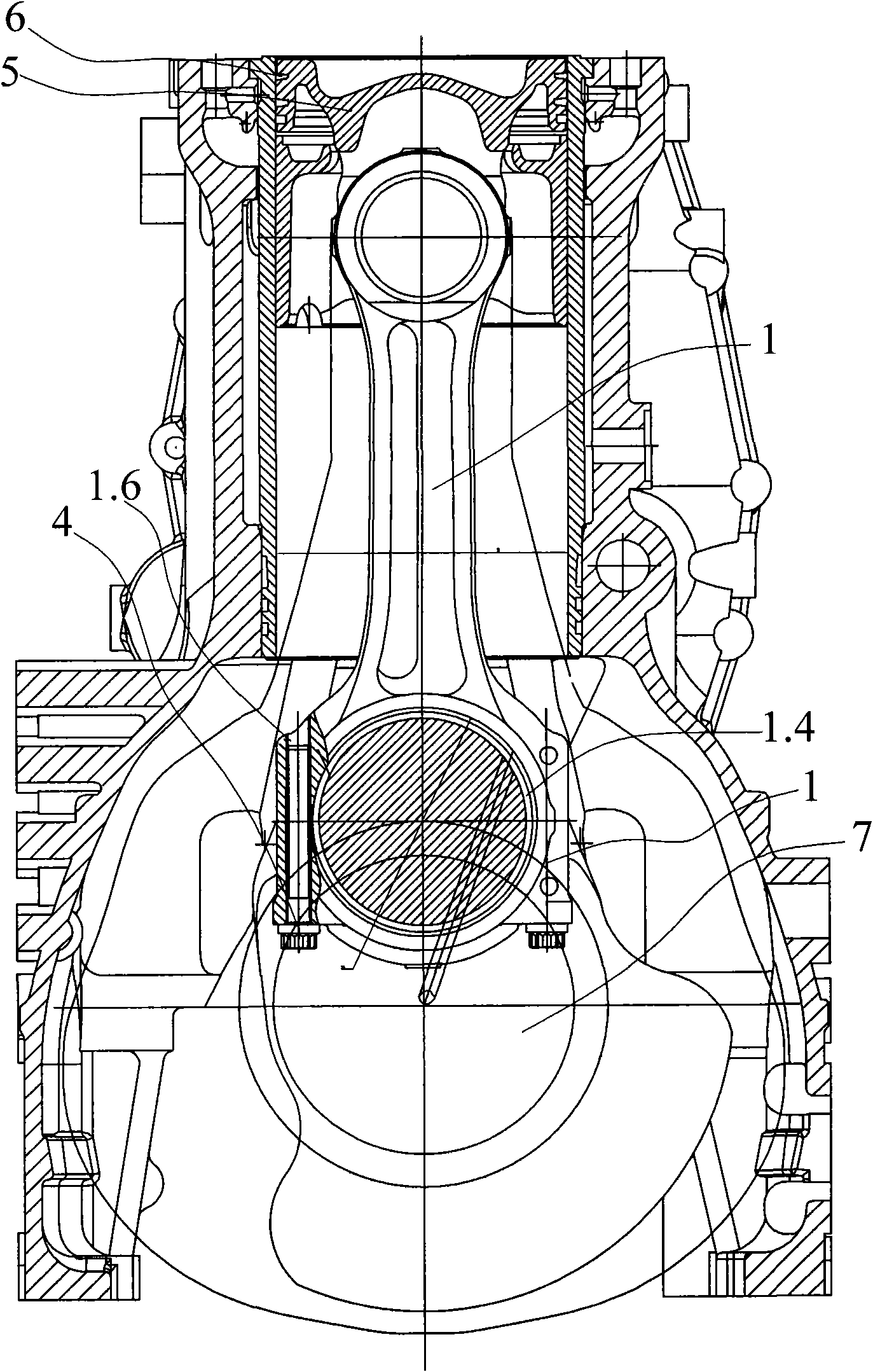

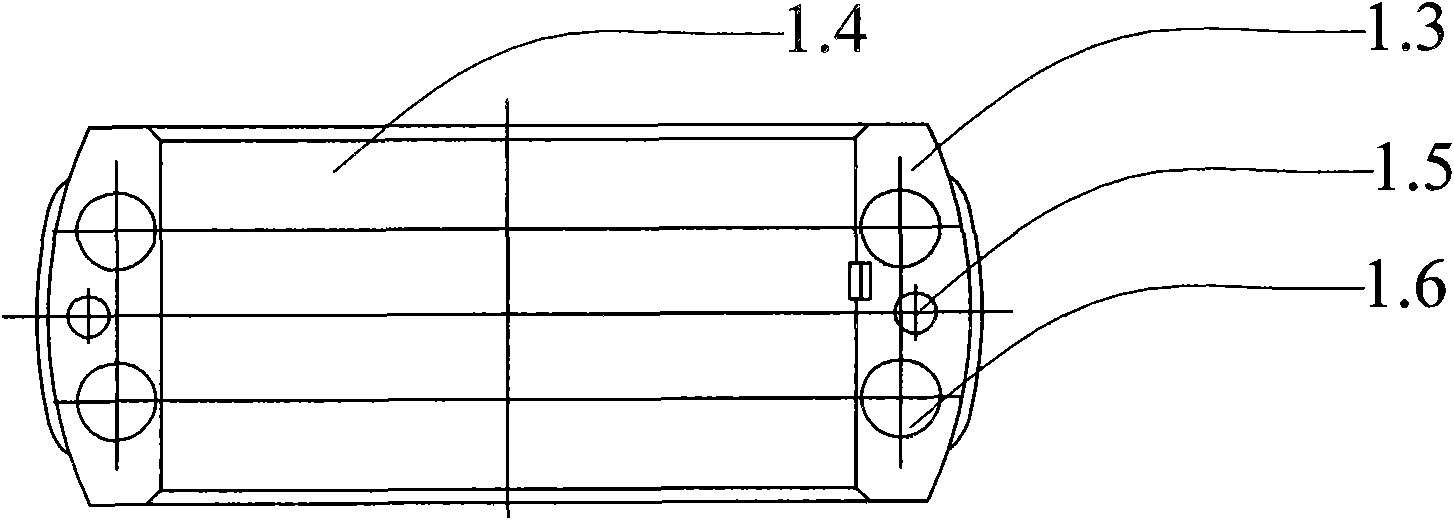

Connecting rod structure for engines

InactiveCN101865203ANo change in thicknessEven by forceConnecting rod bearingsConnecting rodsEngineeringScrew thread

The invention relates to an engine accessory, in particular to a connecting rod structure for engines. The connecting rod structure mainly comprises a connecting rod body and a connecting rod cover. The connecting rod structure is characterized in that: both the left and the right sides of the connecting rod cover are provided with two upper bolt holes, both the left and the right sides of a big connecting rod end are provided with two lower bolt holes, connecting rod bolts are correspondingly screwed in the upper bolt holes and the lower bolt holes on the same side, an upper positioning pin hole is arranged between the corresponding upper bolt holes, and a lower positioning pin hole is arranged between the corresponding lower bolt holes. Since the connecting rod body is provided with the screw holes, connecting rod bolts can be used for directly locking the connecting rod body and the connecting rod cover, so that connecting rod nuts are dispensed with, the connecting rod structure can be improved from the conventional flat-cut model, the connecting rod can be uniformly stressed, the strength of the connecting rod is higher than the strength of the connecting rod with two bolts by calculation and analysis, the development cycle is short, and machining is easy.

Owner:WUXI KIPOR POWER CO LTD

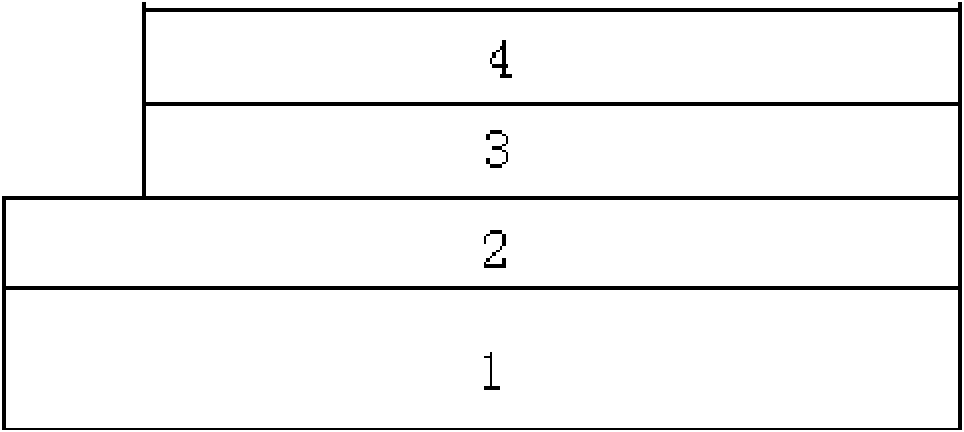

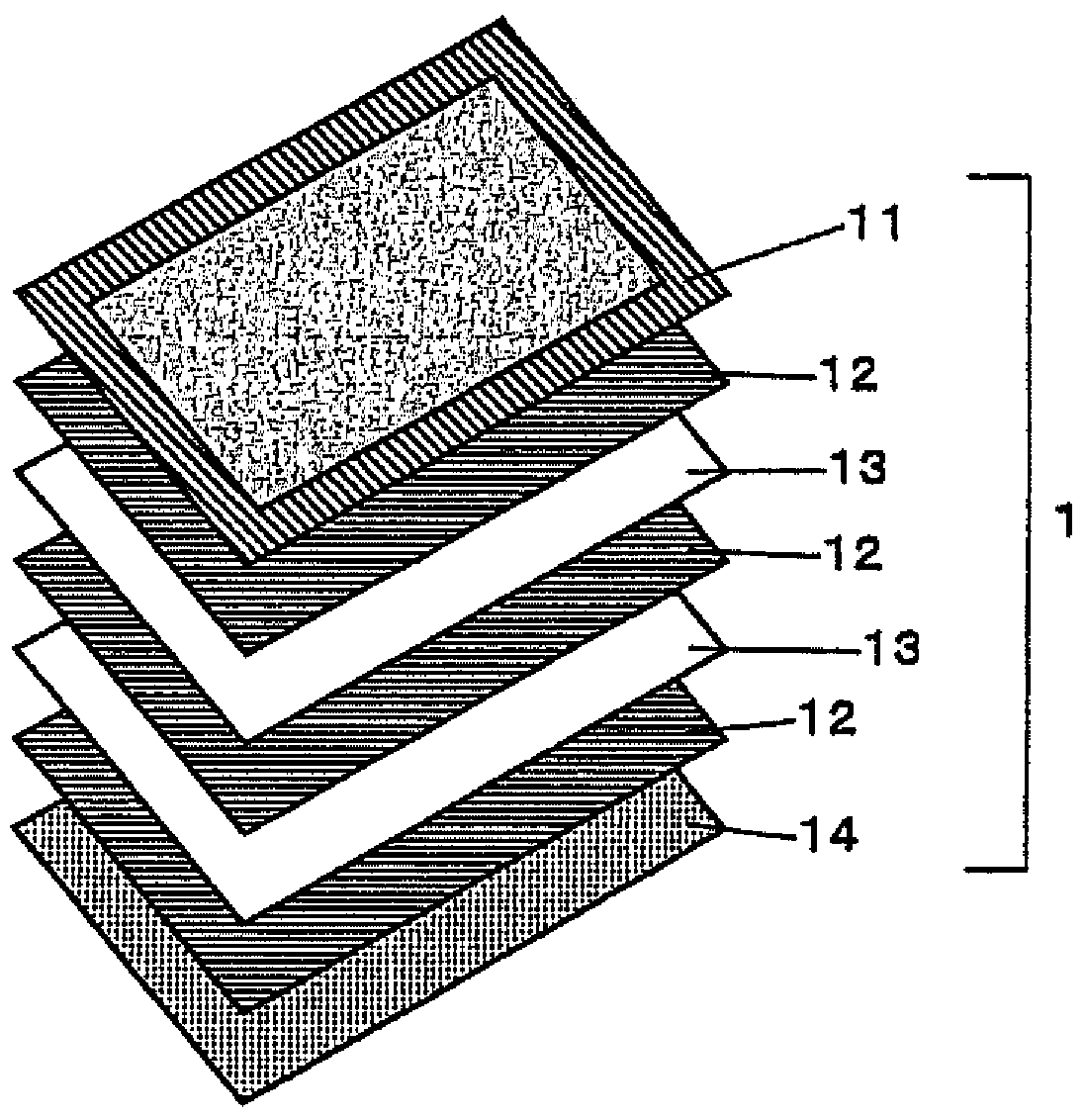

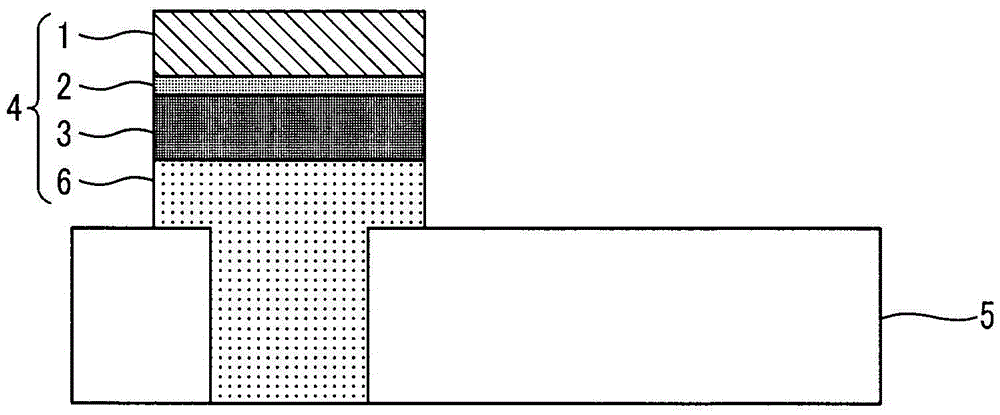

Sandwich anode structure of organic electroluminescent device and preparation method thereof

InactiveCN102054938AIncrease brightnessIncrease Luminescence Enhancement FactorSolid-state devicesSemiconductor/solid-state device manufacturingChemical vapor depositionLight-emitting diode

The invention provides a sandwich anode structure of an organic electroluminescent device and a preparation method. The preparation method comprises the following steps: firstly, a transparent conductive oxide film is deposited on a transparent glass substrate by adopting the methods of sputtering, chemical vapor deposition, spraying pyrolysis, sol-gel or pulsed laser deposition; secondly, a metallic film is deposited on the transparent conductive oxide film through vacuum evaporation; and eventually, metal oxide or a metal oxide / organic matter doped layer is deposited on the metallic film through vacuum evaporation. The novel anode structure provided by the invention is adopted to effectively improve the hole injection capability and improve the performance of an OLED (Organic Light Emitting Diode) device.

Owner:SHAANXI UNIV OF SCI & TECH

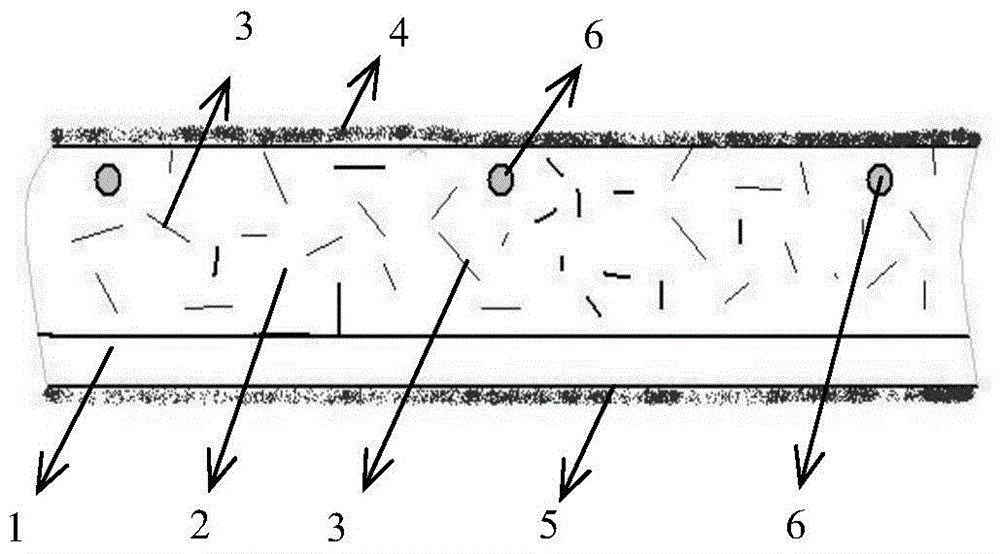

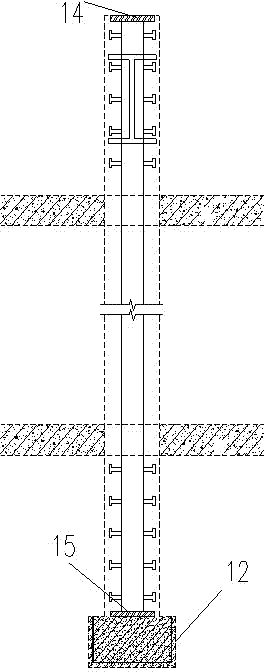

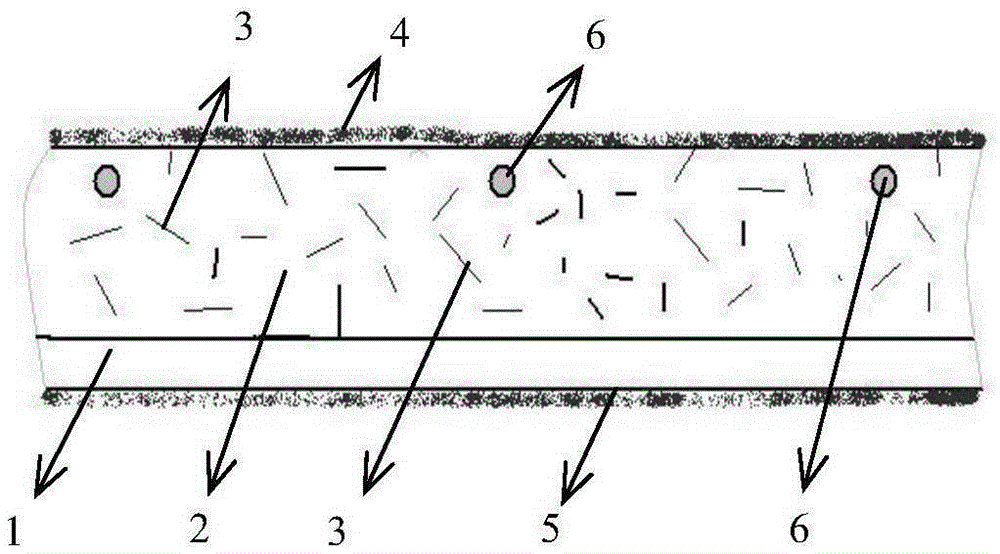

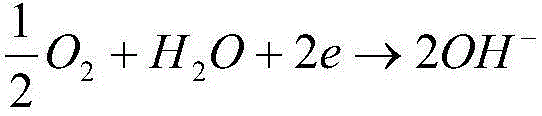

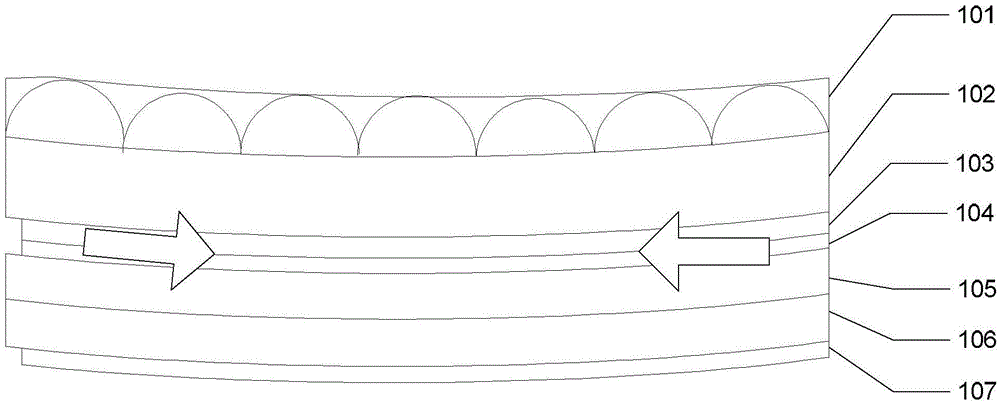

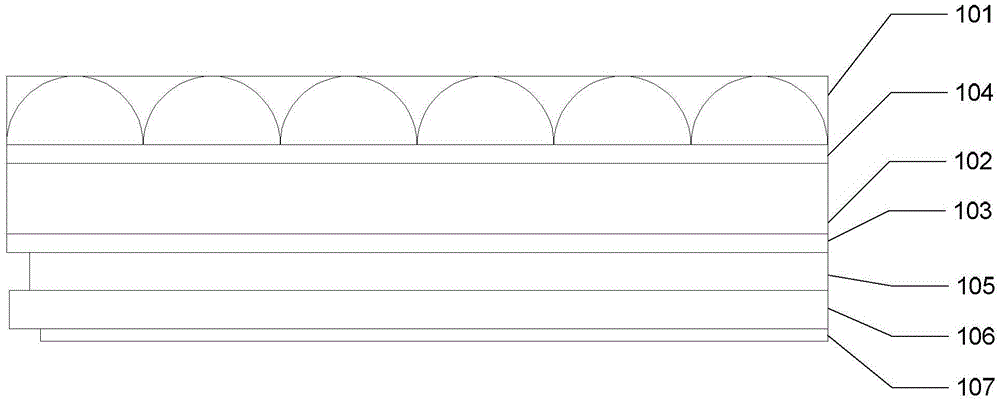

Ion exchange membrane for superhigh-current-density oxygen cathode electrolysis and preparation method thereof

ActiveCN103556178AHigh mechanical strengthIncreased electrochemical fluxOrganic diaphragmsHigh current densityComposite film

The invention relates to an ion exchange membrane for superhigh-current-density oxygen cathode electrolysis and a preparation method thereof. The ion exchange membrane is a multilayer composite film composed of a perfluorocarboxylic acid ion exchange resin layer, a carbon-nanotube-containing perfluorosulfonic acid ion exchange resin layer, a reinforcing mesh, a sulfonic acid side gas release coating and a carboxylic acid side multifunctional coating, wherein the total thickness of the basal membrane of the perfluorinated ion exchange membrane is 90-180 micrometers, the thickness of the perfluorosulfonic acid resin layer is 80-160 micrometers, the thickness of the perfluorocarboxylic acid resin layer is 8-16 micrometer, and the thickness of the two side surface coatings of the membrane is respectively 3-12 micrometers. The membrane can be prepared by a melt coextrusion or multilayer hot-press compounding technique. The membrane is used for an oxygen cathode electrolysis technique, is especially suitable for ion-exchange-membrane-process caustic soda production by a superhigh-current-density oxygen cathode electrolysis technique, and has favorable mechanical properties and electrochemical properties.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

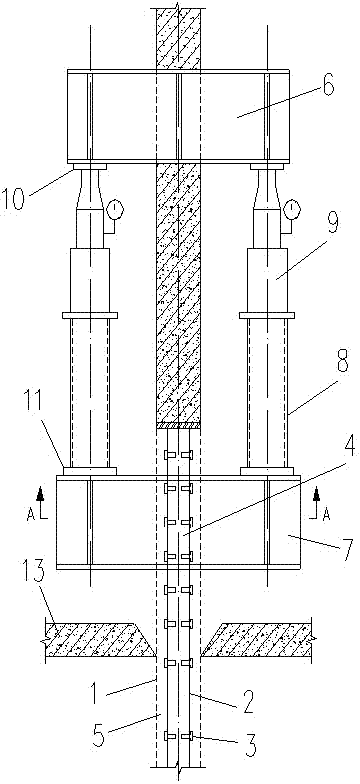

Method for designing and constructing prestressed section steel reinforced shear wall

ActiveCN104499608AImprove bearing capacityEasy constructionWallsShock proofingHigh strength concreteRebar

The invention discloses a method for designing and constructing a prestressed section steel reinforced shear wall. The method includes the following steps: a, determining a reinforcing section according to detection and calculation results, and selecting multiple sections of short section steel according to length of the reinforcing section, wherein multiple pegs are welded on the outer surface of the short section steel, section steel grooves are formed in the shear wall along the height direction, and local replacement grooves are formed in a wall body at the bottom of the section steel grooves; b, arranging a counterforce frame and mounting the section steel; c, pouring high-strength concrete in the local replacement grooves and maintaining, wherein a lower end plate contacts with the high-strength concrete; d, restoring original shear wall rebars; 3, applying prestress; f, erecting a formwork, pouring and maintaining; g, demounting the counterforce frame. By the above mode, the method does not need temporary supporting and is convenient in construction, construction period can be shortened greatly, original structure form is unchanged, thickness of an original shear wall is unchanged, and load-bearing capacity of the shear wall is improved remarkably.

Owner:JIANGSU DINGDA BUILDING NEW TECH +2

Adhesive agent composition, adhesive agent layer, and adhesive sheet

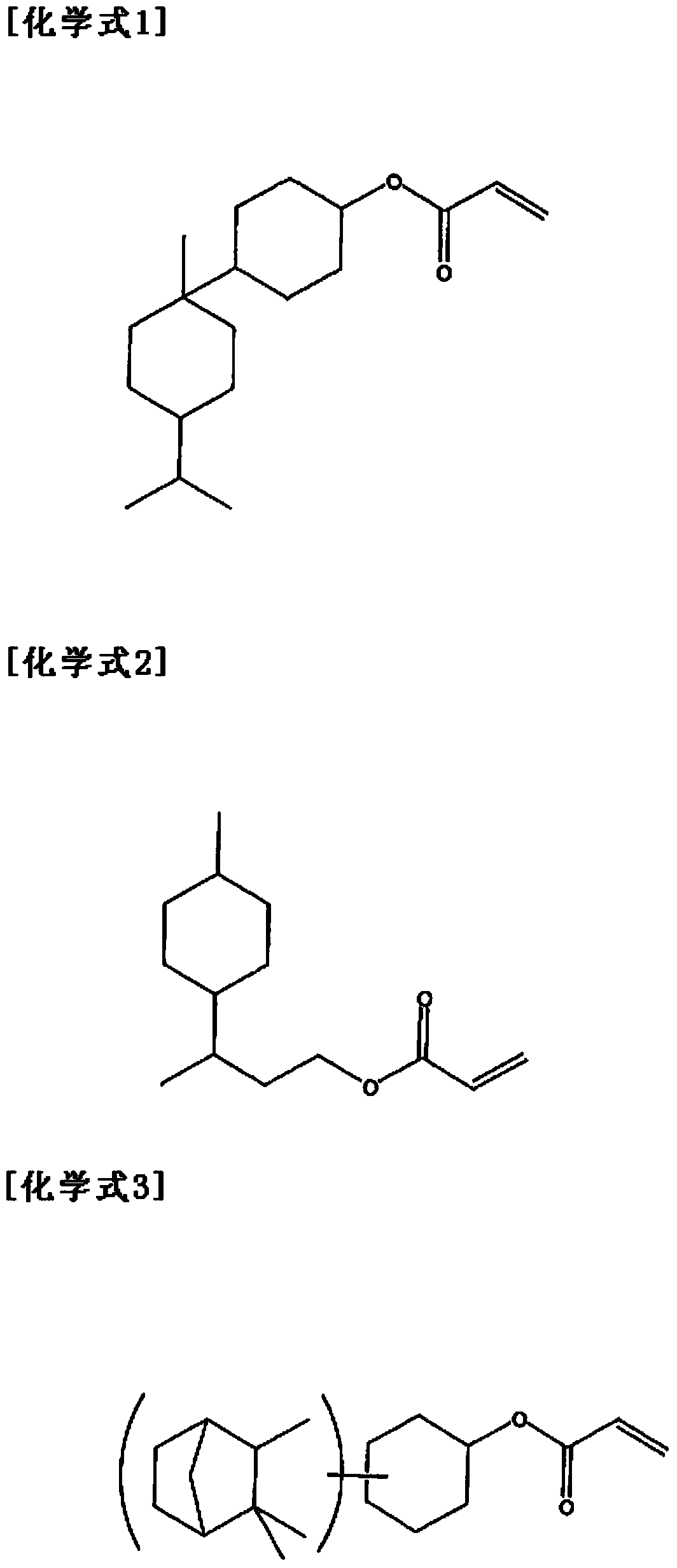

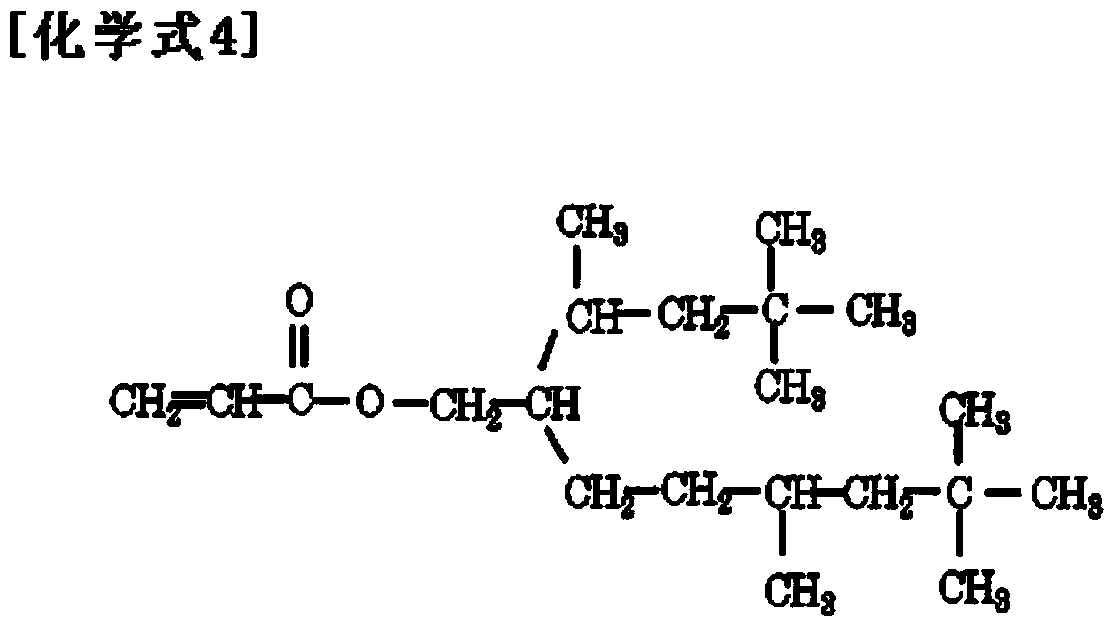

InactiveCN103619977ALow dielectric constantGood adhesivenessSynthetic resin layered productsEster polymer adhesivesMeth-Polymer chemistry

An adhesive agent composition according to the present invention contains a (meth)acrylic polymer which is produced by polymerizing a monomer component comprising 25-99.5 wt% of a monomer containing a cyclic structure and 0.5-70 wt% of a (meth)acrylic monomer containing a branched structure, wherein the (meth)acrylic monomer containing a branched structure has a branched alkyl group having 3-18 carbon atoms at an ester terminal thereof. The adhesive agent composition enables the production of an adhesive agent layer that satisfies adhesion performance and has a low dielectric constant.

Owner:NITTO DENKO CORP

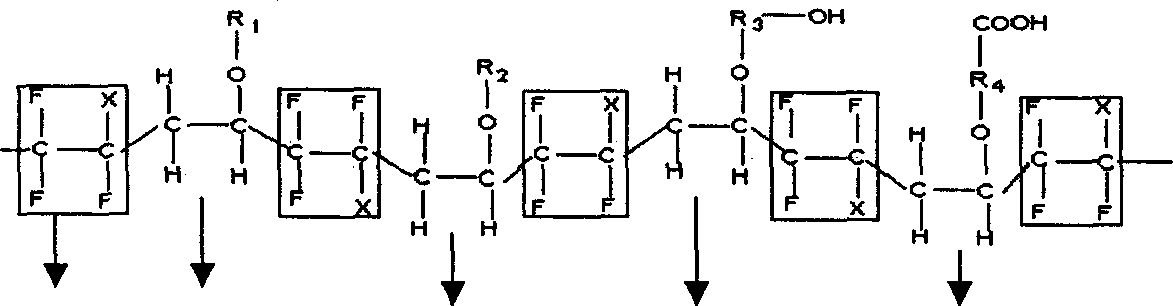

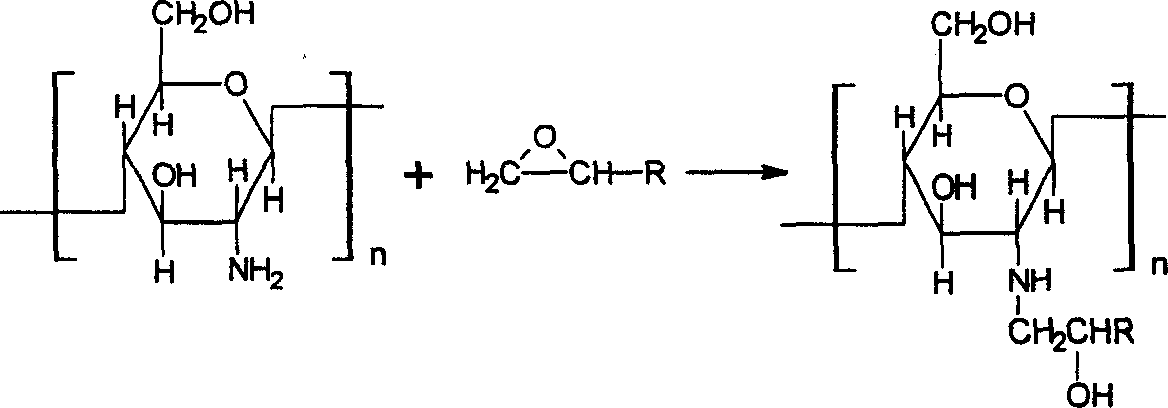

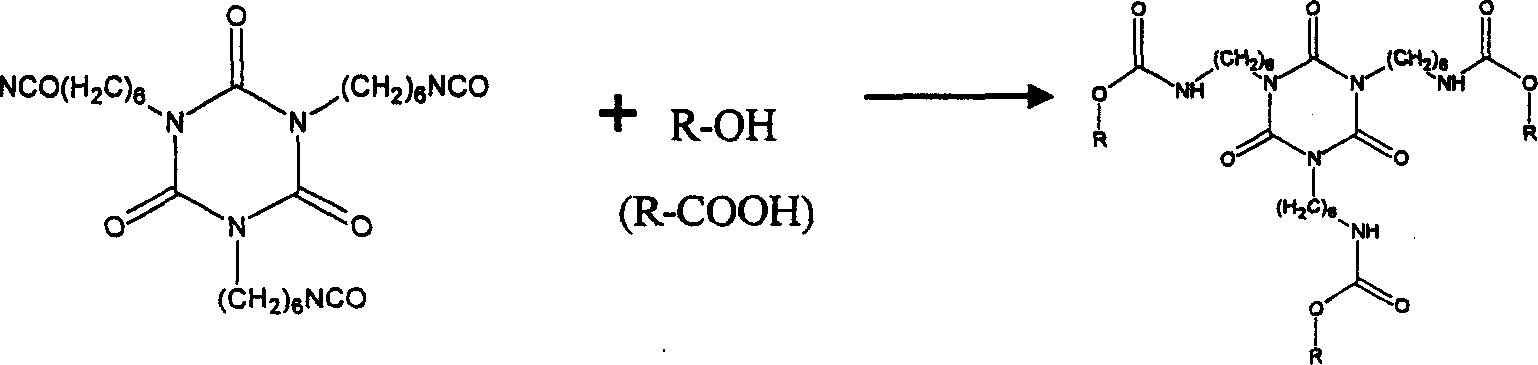

Multifunction reinforcing protection glue for paper historical documents

InactiveCN1773014ADullAging resistantNon-macromolecular organic additionPaper/cardboardViscoseMildew

The present invention relates to a multifunctional viscose solution for strengthening and protecting paper historical document. Its composition includes (by wt%) 12-15% of FEVE fluororesin, 10-14% of hydroxychitosan, 14-20% of HDI cross-linking agent, 4-8% of Zinc oxide nano powder body and 50-60% of N-methyl-pyrrolidone. Said viscose solution also has the mildew-proofing and sterilizing function.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

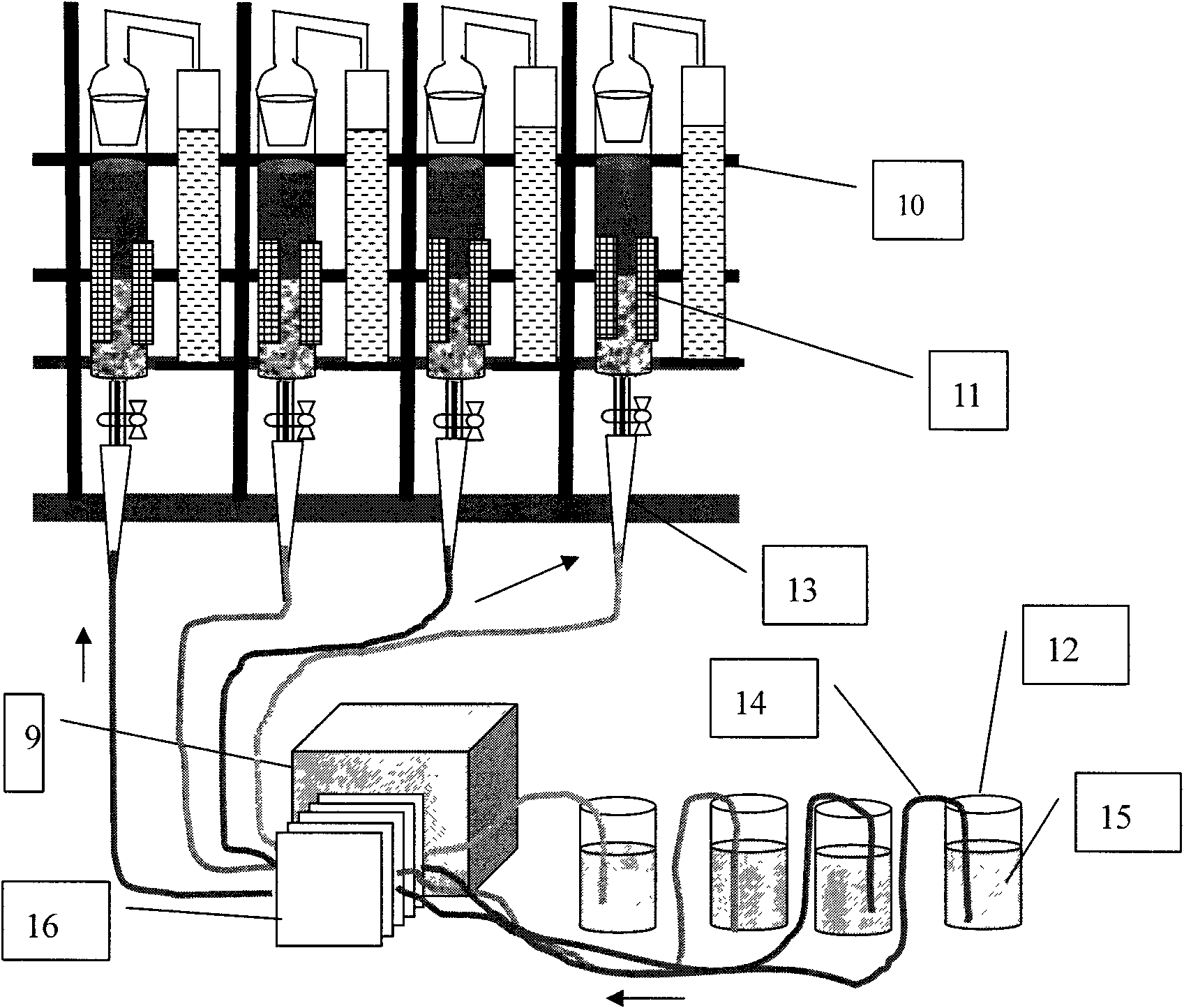

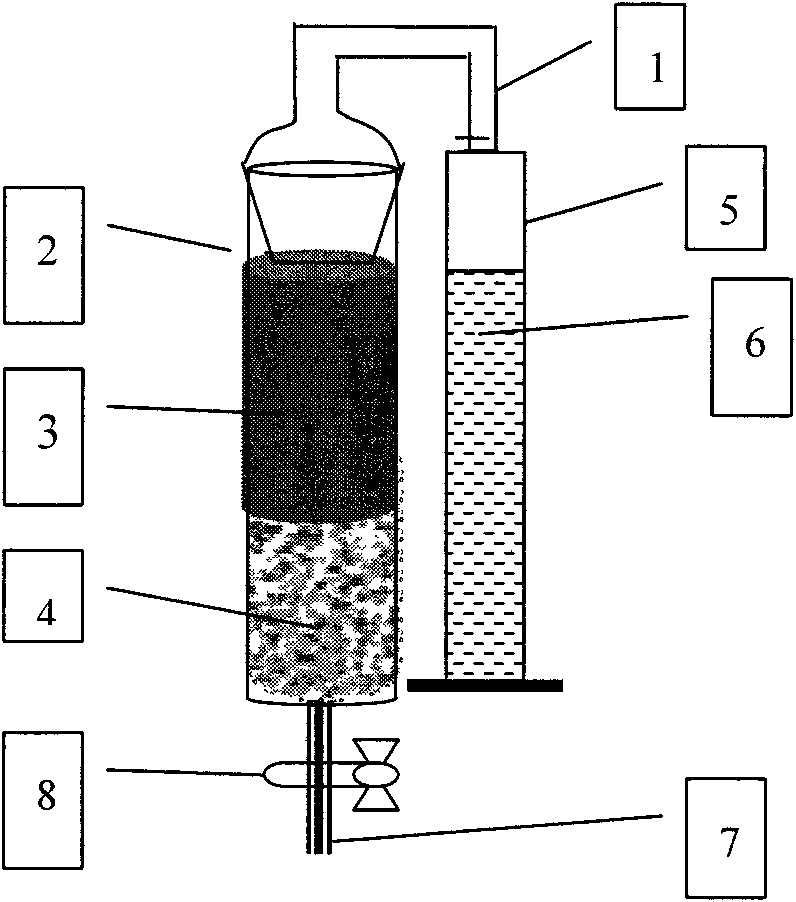

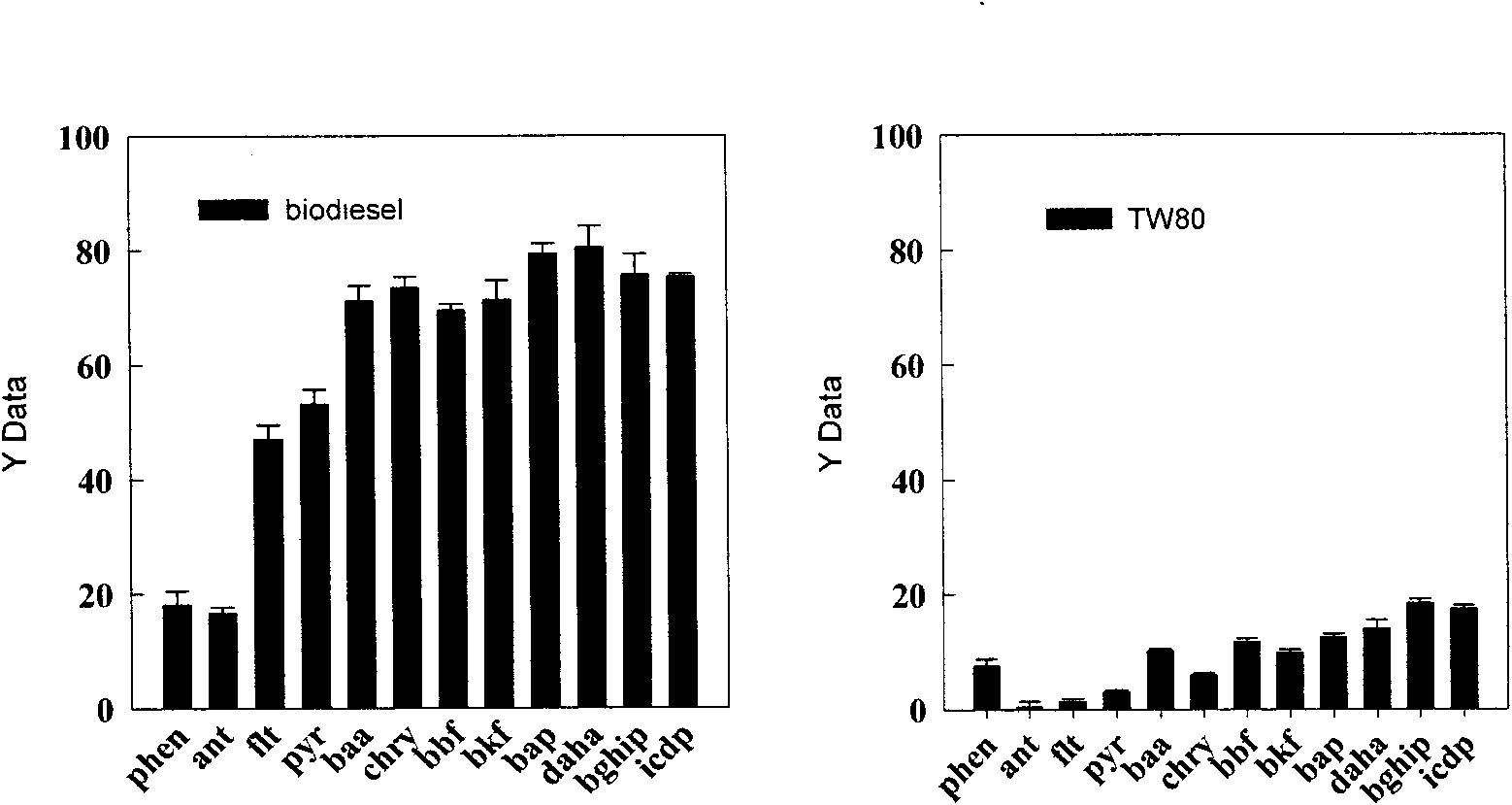

Leaching and removing method and device of PAHs in polluted soil

InactiveCN102145345AOptimization of washing process conditionsRealize practicalityContaminated soil reclamationBiodieselPollution soil

The invention relates to a treatment technology for polluted soil with high content of PAHs (PolycyclicAromaticHydrocarbons), in particular to a leaching and removing method and device of PAHs in polluted soil. The leaching and removing method of PAHs in polluted soil comprises the steps of: laying glass wools used for avoiding the polluted soil moving vertically along with a leacheate on and under the polluted soil arranged in a leaching column, and then enabling the leacheate to move from bottom to top in the leaching column to leach the polluted soil so as to remove the PAHs pollutants, wherein biodiesel is adopted as the leacheate. The leaching and removing device of PAHs comprises the leaching column, a draining pipe and a collecting cup, wherein a liquid inlet controlled by a switch is arranged at the lower end of the leaching column, and the upper end of the leaching column is connected with the collecting cup through the draining pipe. The leaching and removing method provided by the invention has high efficiency for treating polluted soil with high content of PAHs. When the leaching and removing method and device are used for treating the soil of a gas plant, the biodiesel is adopted as the leacheate when the total amount of 12 types of PAHs in soil is 996.85 mg / kg; and when the ratio of the leacheate to the soil (v / w) is 2:1, the total amount of PAHs in the soil can be reduced to 377.03 mg / kg, and the removing rate of all the 12 types of PAHs is 62.18 percent.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

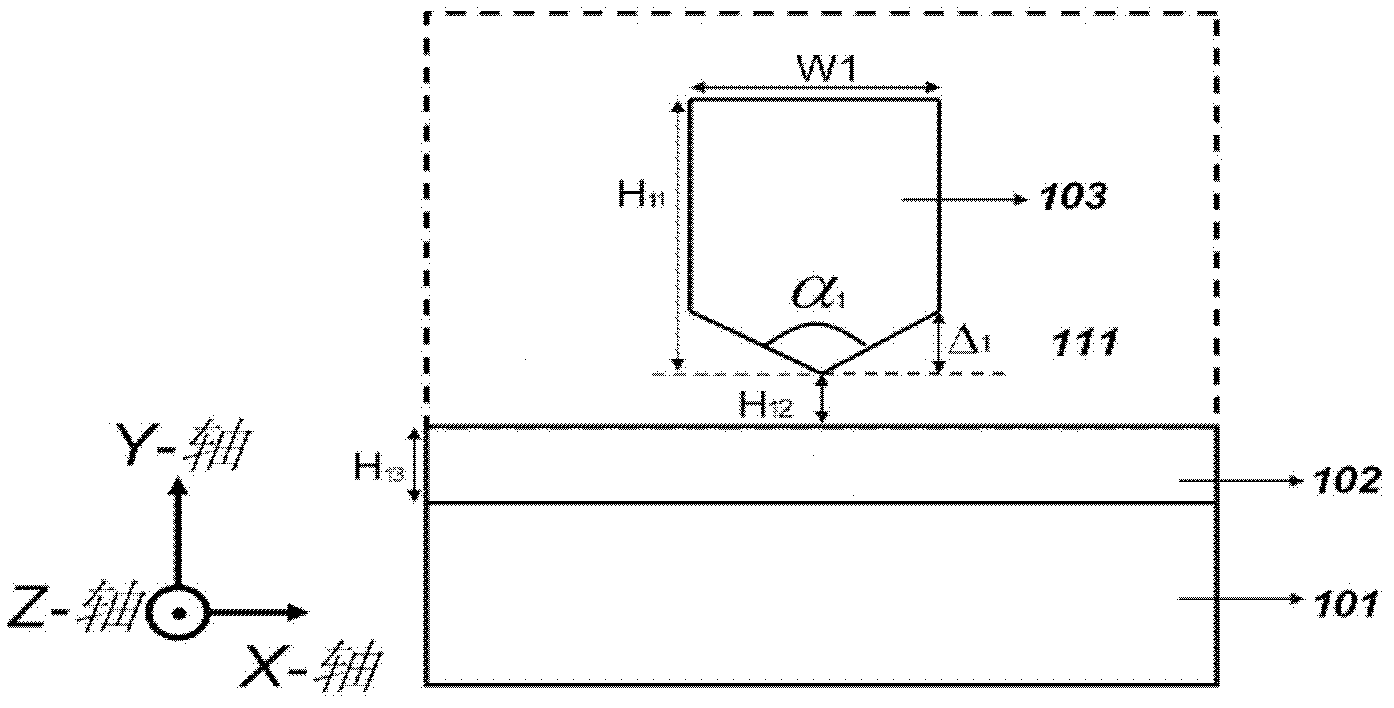

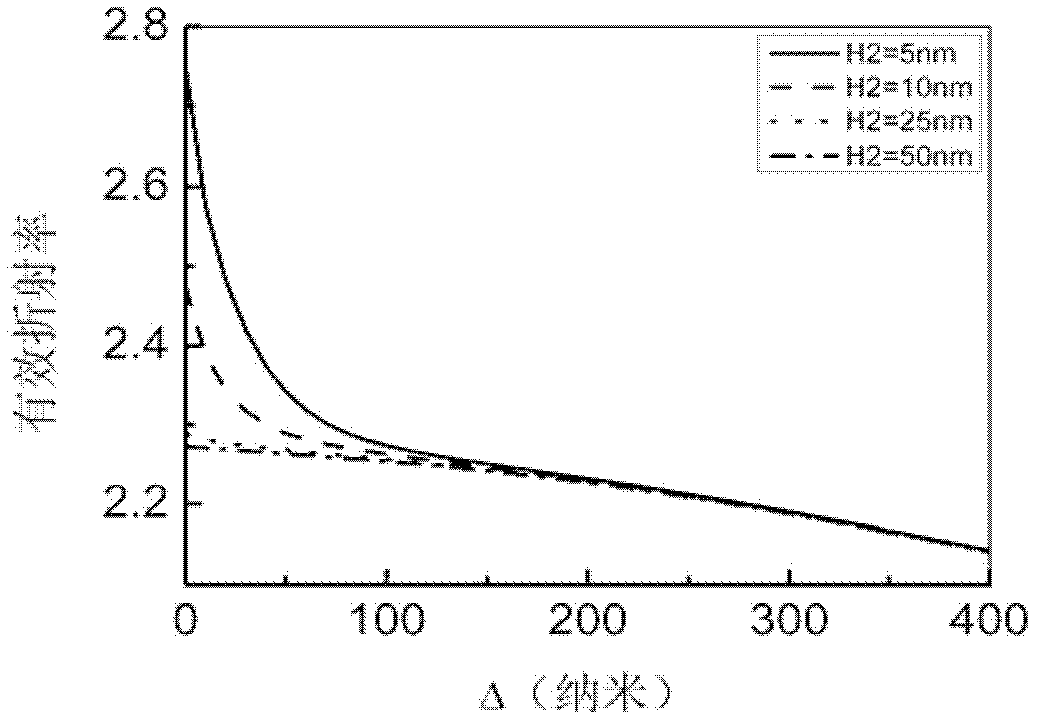

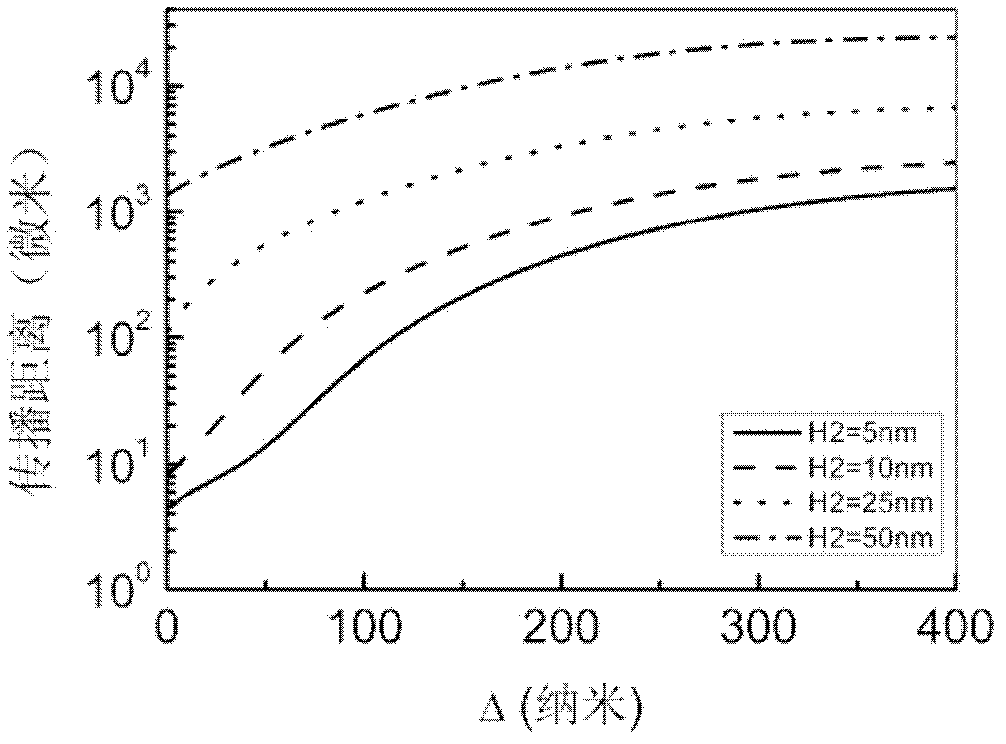

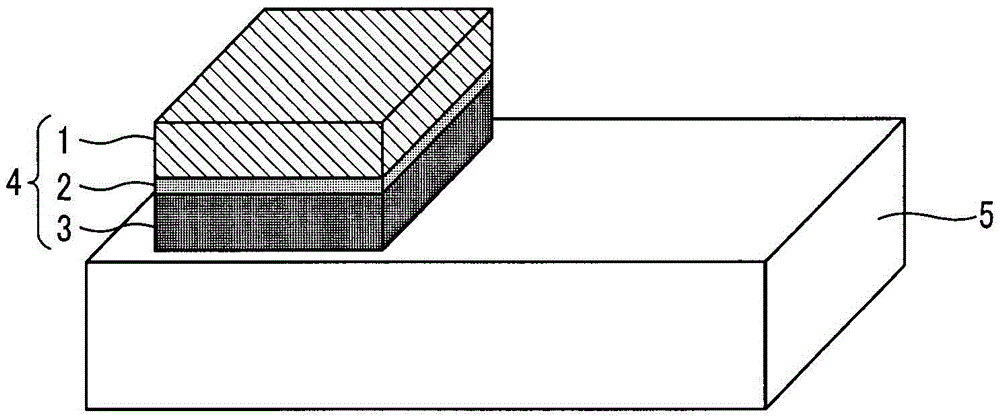

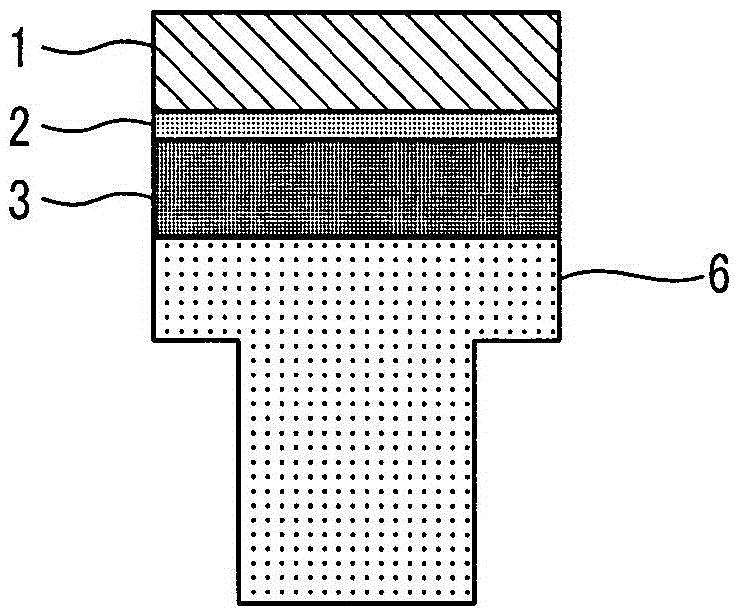

Plasma excimer gain waveguide

ActiveCN102662210AImprove localityExtended propagation distanceOptical waveguide light guideCouplingIsolation layer

The invention relates to the field of optical waveguide technology. The invention provides a plasma excimer gain waveguide, including a base layer, a medium layer, an isolation layer and a gain waveguide. The medium layer is placed on the bare surface of the base layer. The isolation layer is between the medium layer and the gain waveguide. One end of the gain waveguide near the dielectric layer is wedge-shaped and the tip faces the dielectric layer. The refractive index of the gain waveguide is greater than that of the isolation layer. The plasma excimer gain waveguide has the advantages that one end of the gain waveguide near the dielectric layer is wedge-shaped, the distance between the top of the wedge-shaped structure and the metal is fixed, the isolation layer with low refractive index is kept, and the plasma excimer coupling of the gain waveguide and the metal is improved by adjusting the angle of the wedge-shaped point angle.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

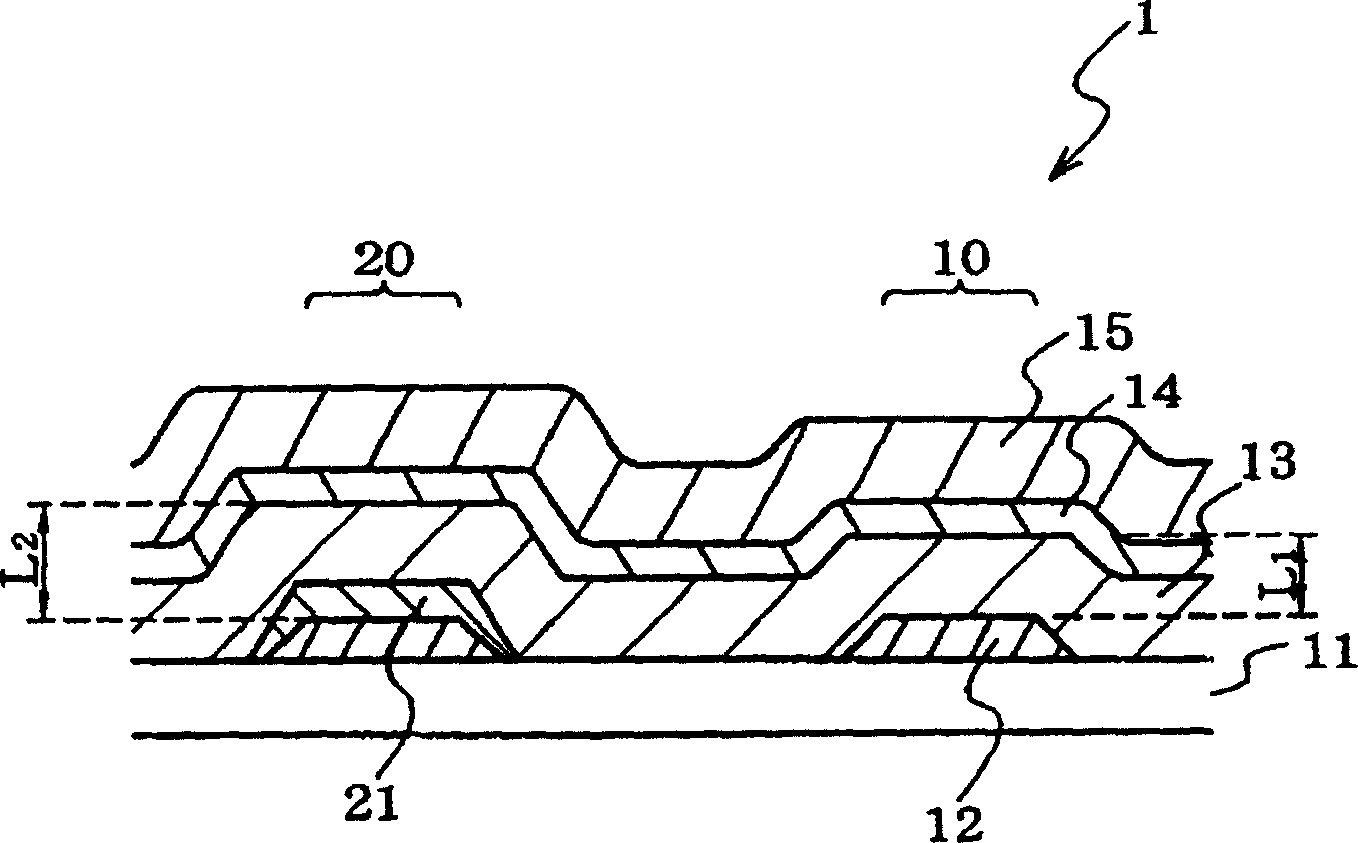

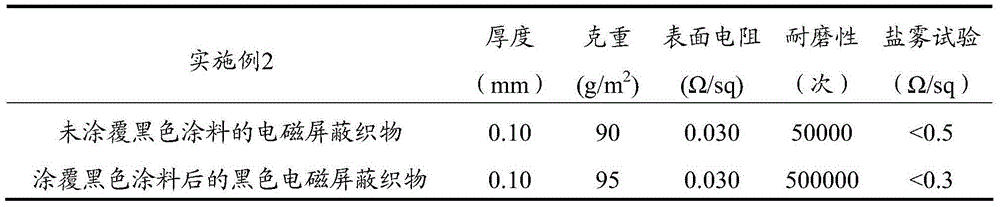

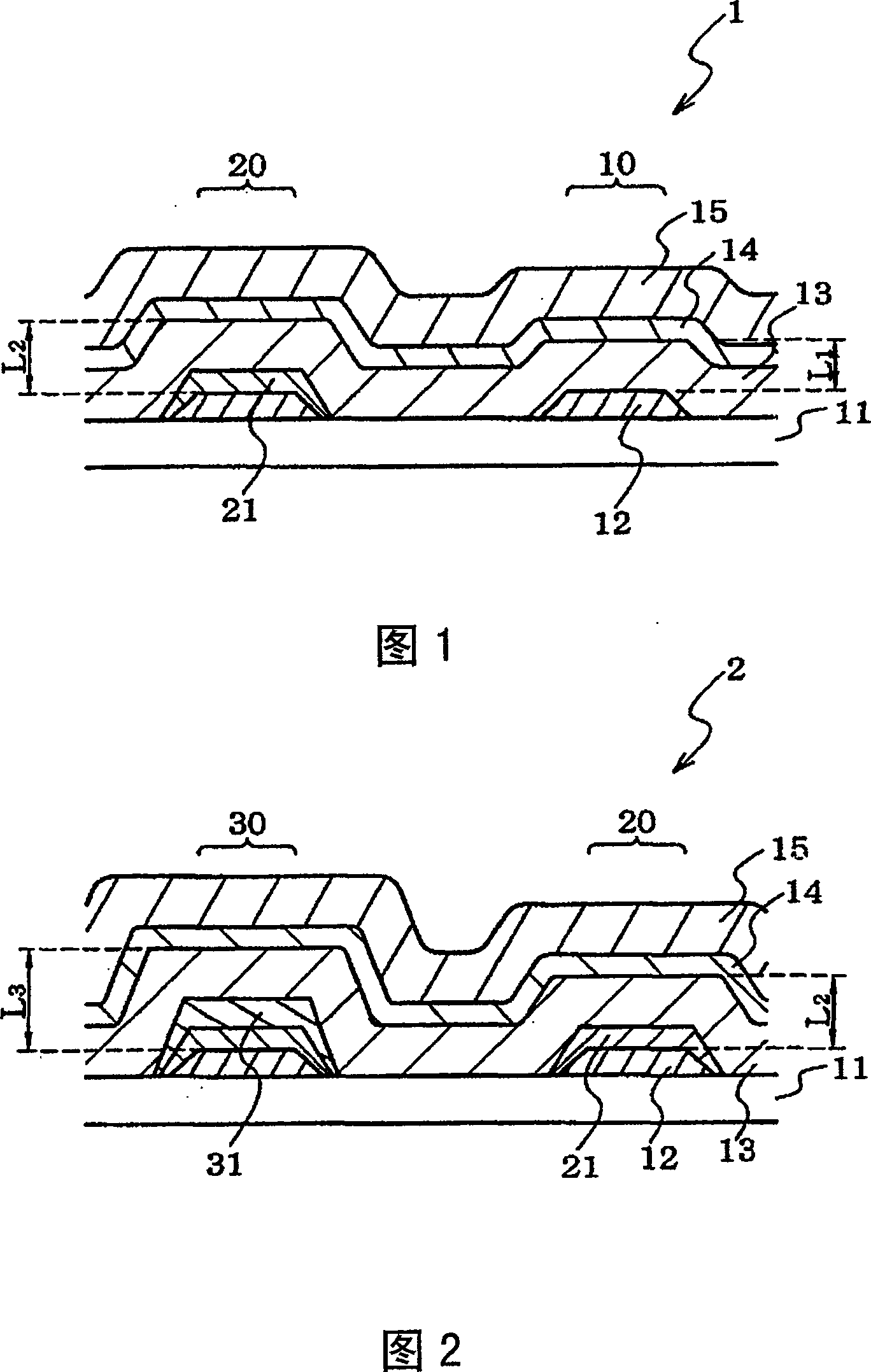

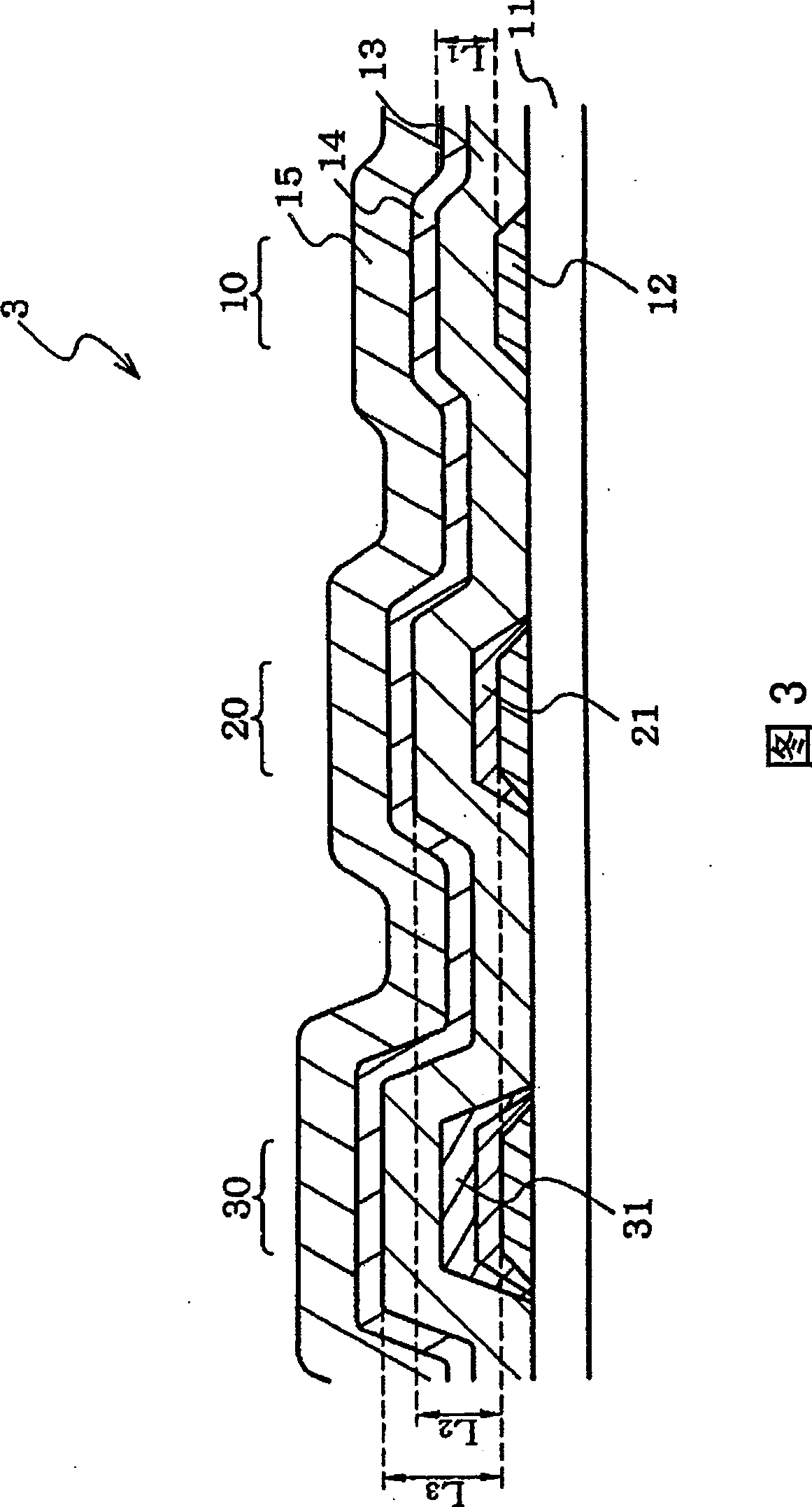

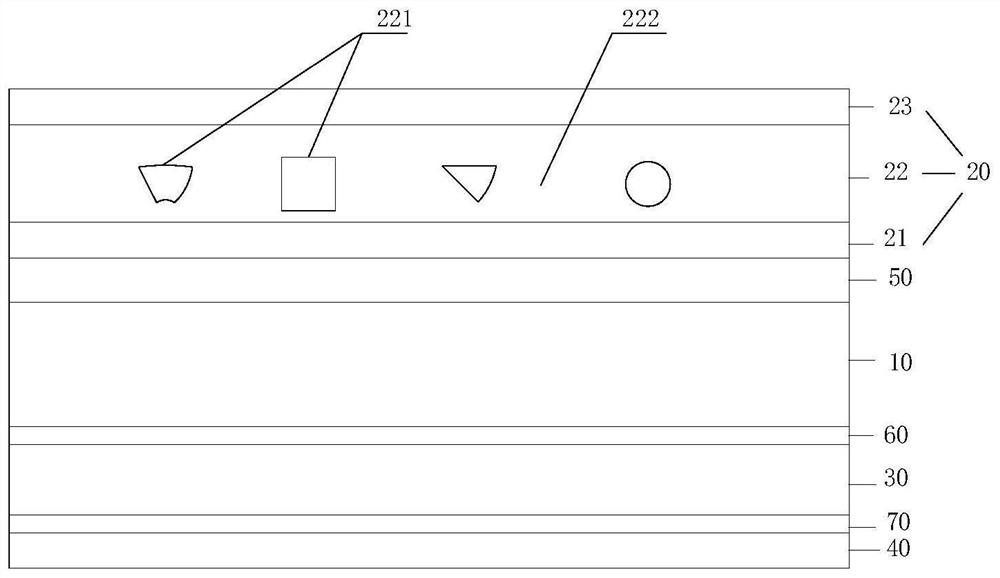

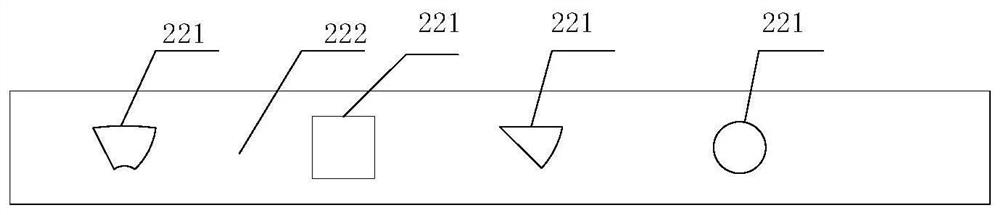

Organic electroluminescence display device

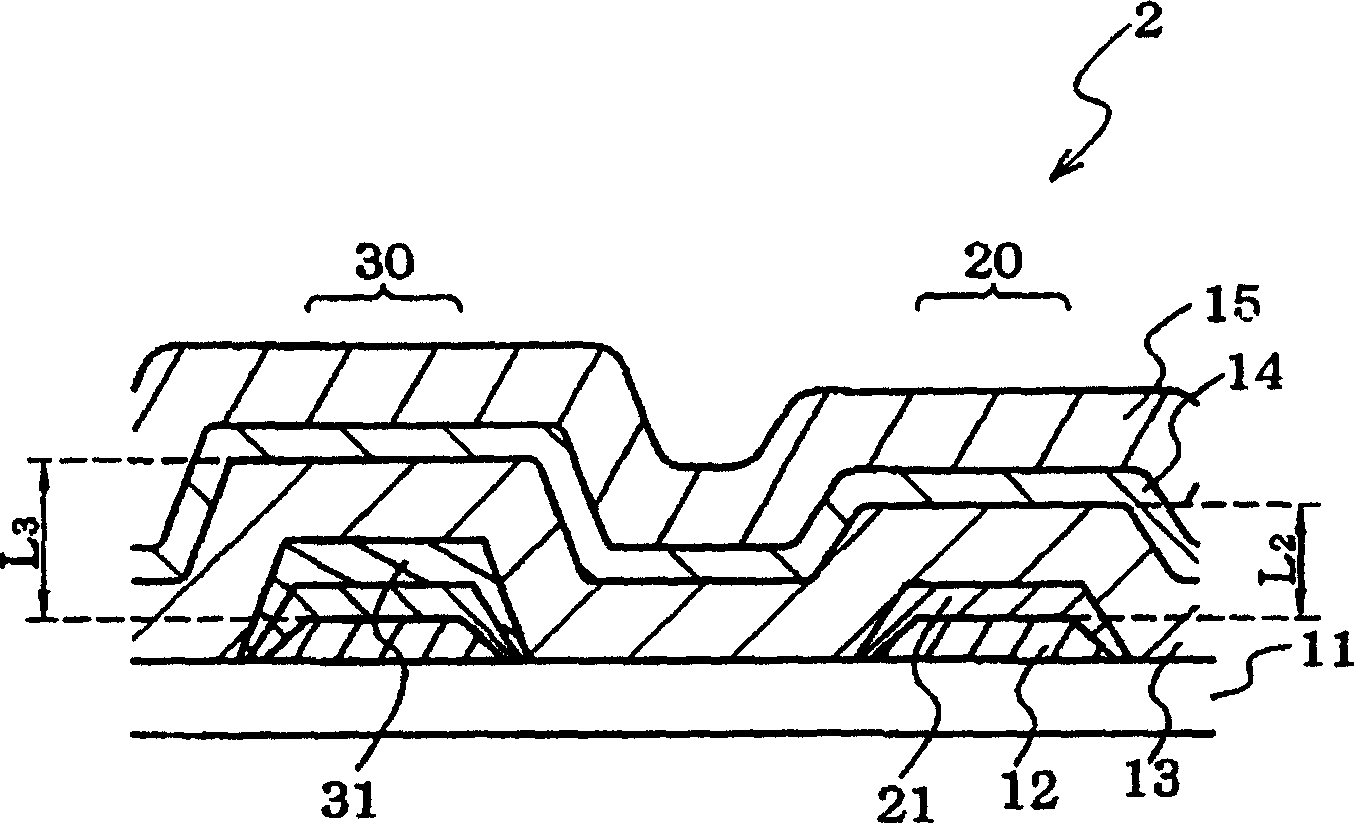

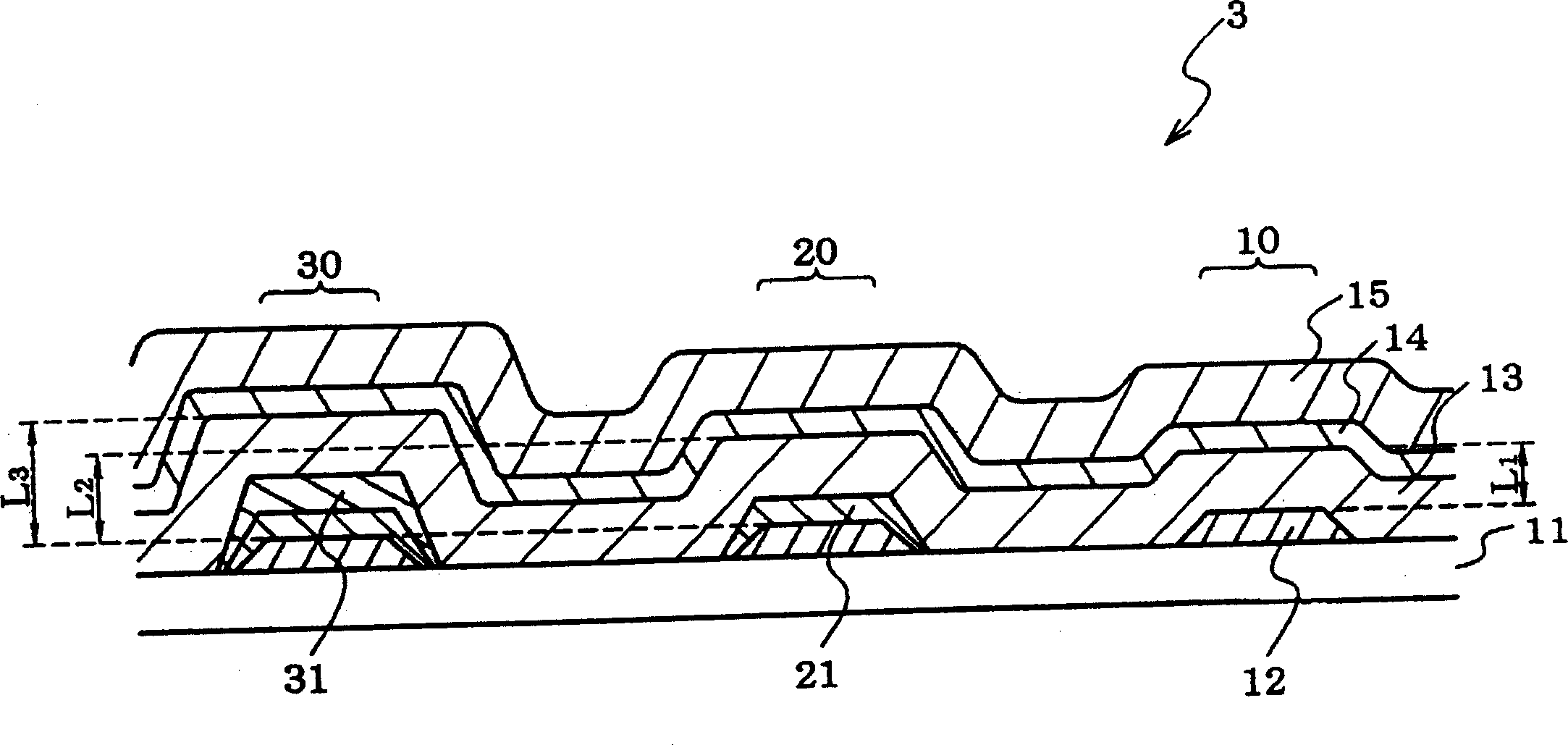

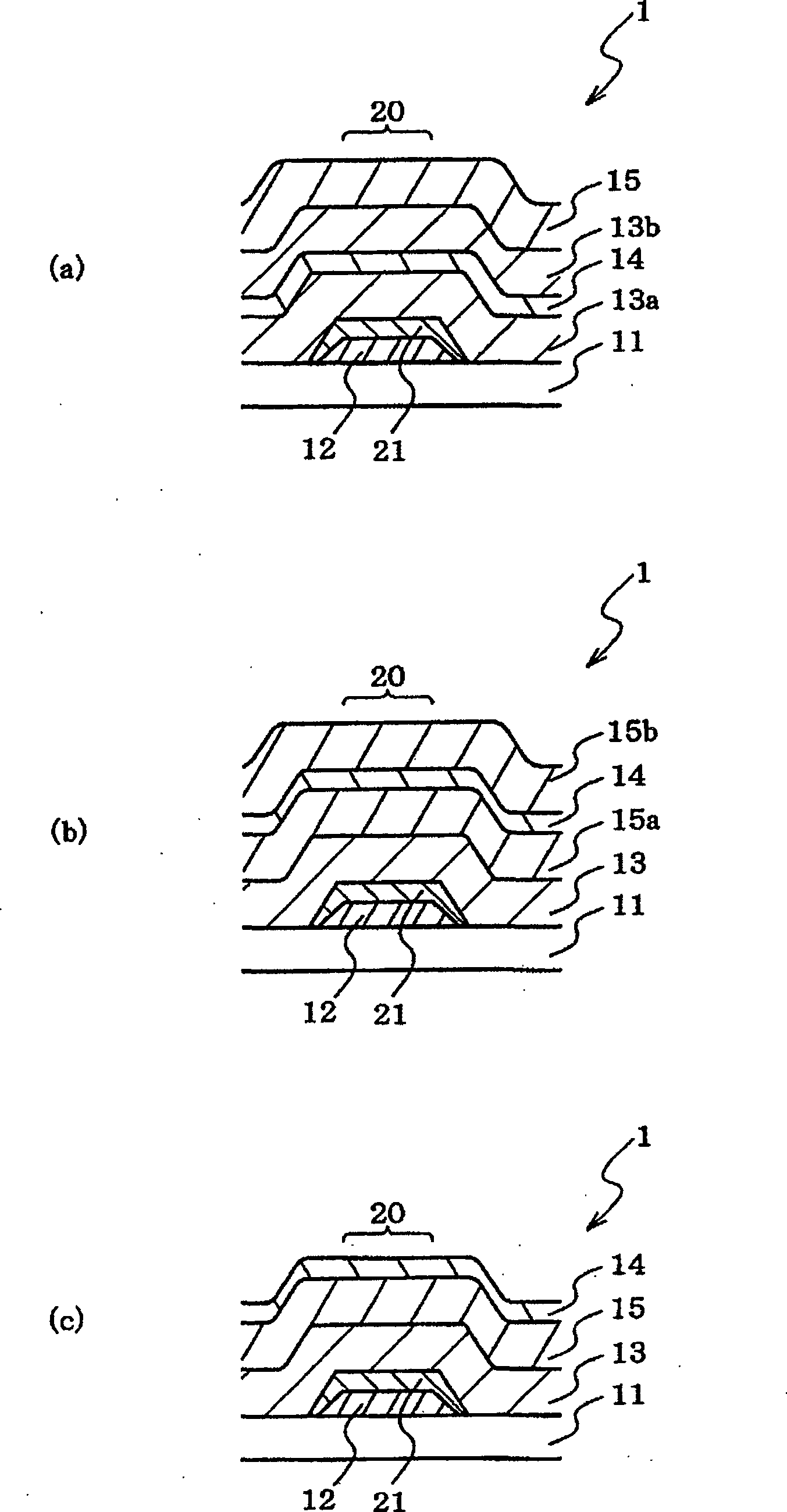

ActiveCN1914958ADoes not reduce luminous efficiencyAchieve multi-color light emissionElectrical apparatusElectroluminescent light sourcesOrganic electroluminescenceMedia layer

The invention provides an organic EL display device, which has a substrate (11), and a first organic EL element part (10) and a second organic EL element part (20) juxtaposed on the same surface of the substrate; The EL element part (10) comprises at least a light-reflecting conductive layer (12), an organic light-emitting medium layer (13), and a transparent electrode layer (15) in order, and is formed on the organic light-emitting medium layer (13) or the transparent electrode layer (15) An element having a light reflective layer (14) inside or outside; the second organic EL element part (20) at least includes a light reflective conductive layer (12), a first inorganic compound layer (21), an organic luminescent medium layer ( 13), and a transparent electrode layer (15) and an element having a light reflection layer (14) inside or outside the organic luminescent medium layer (13) or the transparent electrode layer (15); from the first organic EL element part (10) The emission spectrum of the emitted light is different from that of the light emitted from the second organic EL element unit (20).

Owner:IDEMITSU KOSAN CO LTD

Method for improving lamination strength of lamination components

InactiveCN107748456AHigh bonding strengthReduced risk of degummingLaminationLamination apparatusLiquid-crystal displayEngineering

The invention provides a method for improving the lamination strength of lamination components. The method for improving the lamination strength of the lamination components aims to improve the lamination strength of the lamination components (a liquid crystal display screen and glass, a liquid crystal display screen and a touch screen, and glass and glass). The method is characterized in that a double-sided dry glue lamination mode is adopted, that is, the lamination surface of the lamination component A and the lamination surface of the lamination component B are coated with glue, after theglue is cured at a certain temperature, the components A and B are bonded together, and the double-sided dry glue lamination process is completed. Compared with single-side lamination, double-sided lamination refers to lamination of dry glue and dry glue, direct lamination of the lamination surface and dry glue in single-side lamination process is thus avoided, and the lamination strength of the components is improved. The double-sided dry glue lamination process can effectively improve the lamination strength, the compatibility is high, and the method is suitable for lamination between the liquid crystal display screen, the glass, the touch screen and other components.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

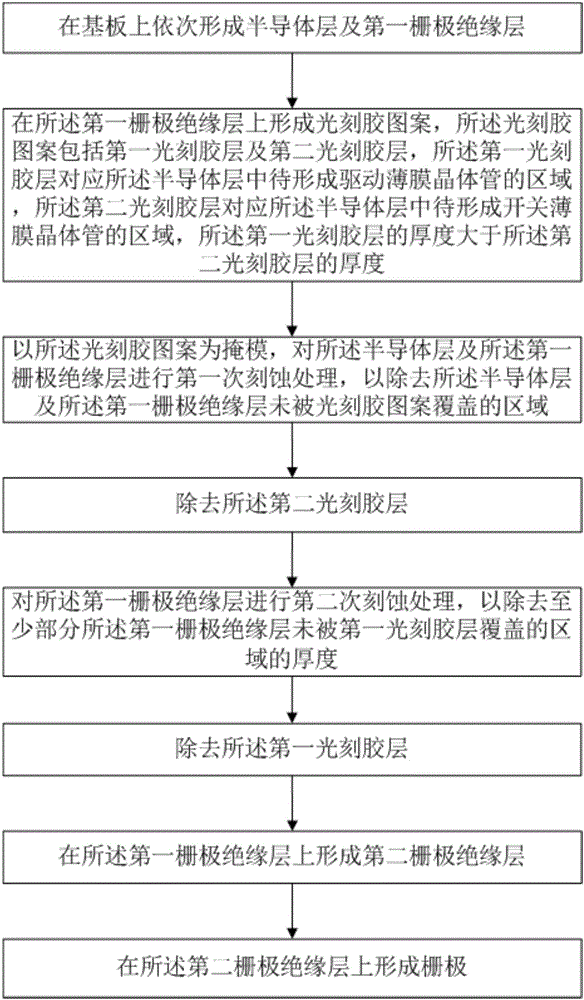

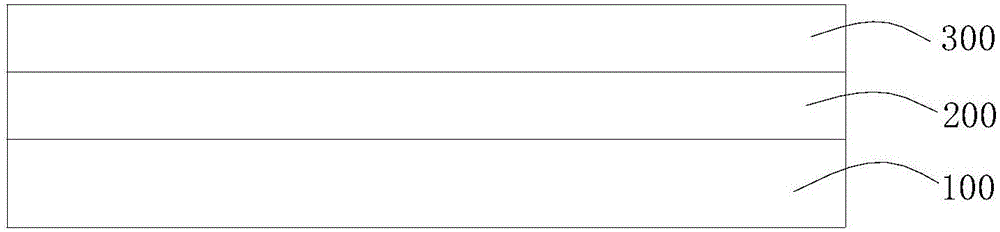

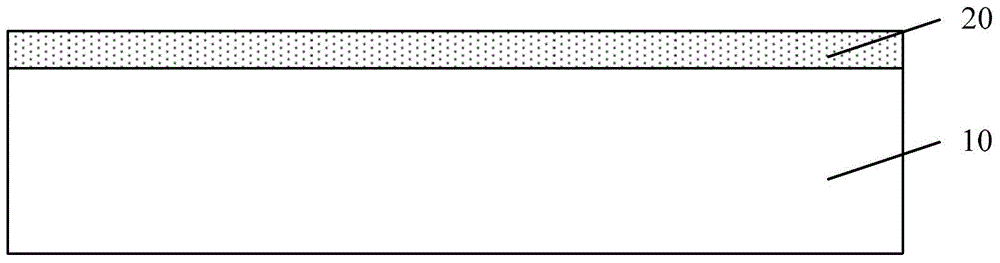

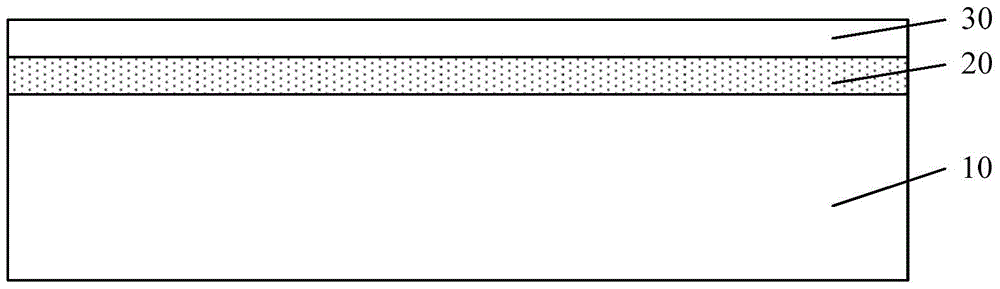

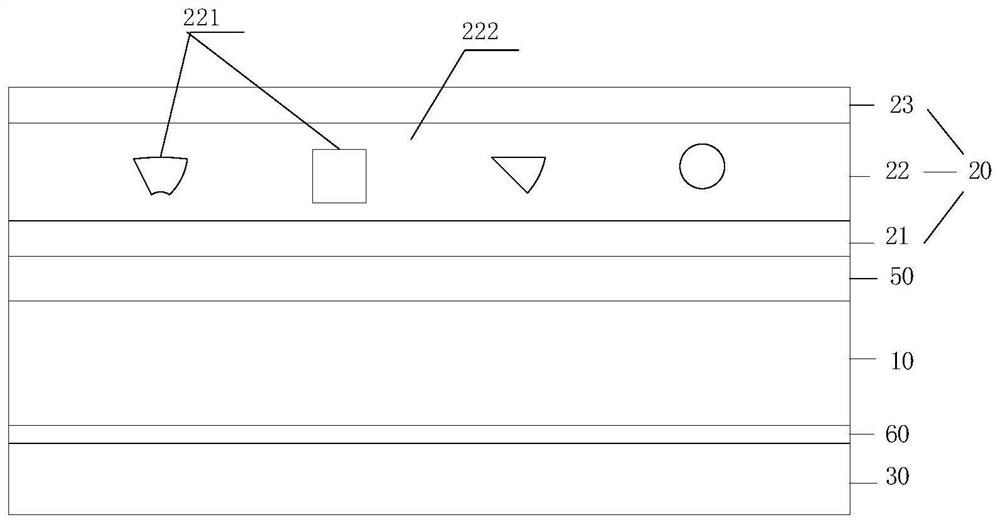

Thin-film transistor and manufacturing method thereof

ActiveCN105702743AIncreased subthreshold swingNo change in thicknessTransistorSemiconductor/solid-state device manufacturingSub thresholdOptoelectronics

The invention provides a manufacturing method of a thin-film transistor. The method comprises the steps of sequentially forming a semiconductor layer and a first grid insulating layer on a substrate; forming a photoresist pattern on the first grid insulating layer, wherein the photoresist pattern comprises a first photoresist layer and a second photoresist layer and the thickness of the first photoresist layer is larger than the thickness of the second photoresist layer; adopting the photoresist pattern as a mask, and etching the semiconductor layer and the first grid insulating layer for the first time; removing the second photoresist layer; etching the first grid insulating layer for a second time to remove the thickness of at least one part of the first grid insulating layer that is not covered by the first photoresist layer; removing the first photoresist layer; forming a second grid insulating layer on the first grid insulating layer; and forming a grid on the second grid insulating layer. Based on the above method for manufacturing the thin-film transistor, the sub-threshold swing for driving the thin-film transistor is increased. Meanwhile, the driving performance of an AMOLED is improved.

Owner:TRULY HUIZHOU SMART DISPLAY

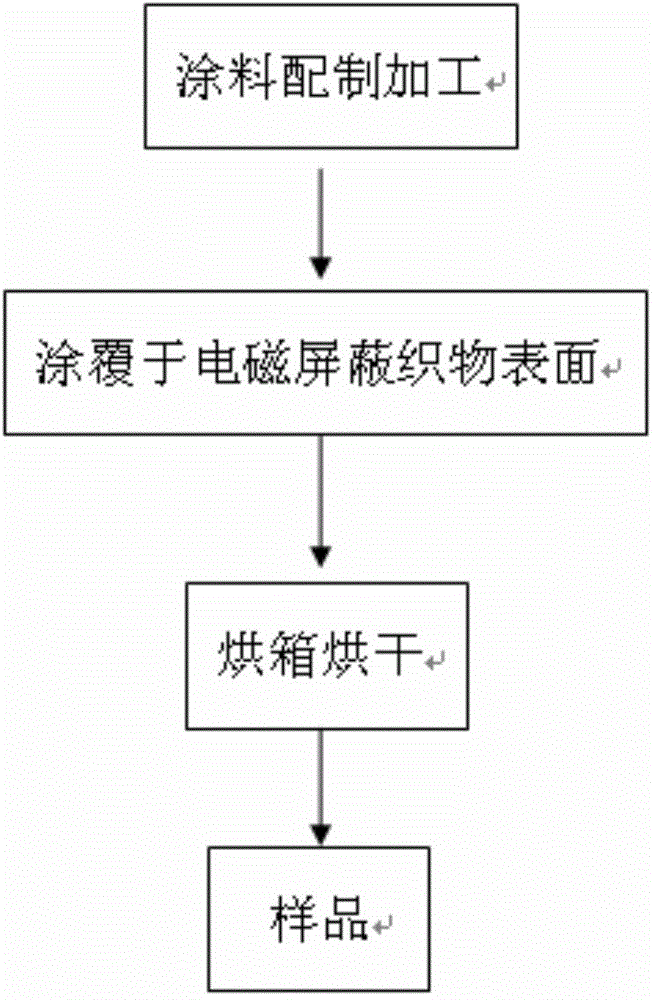

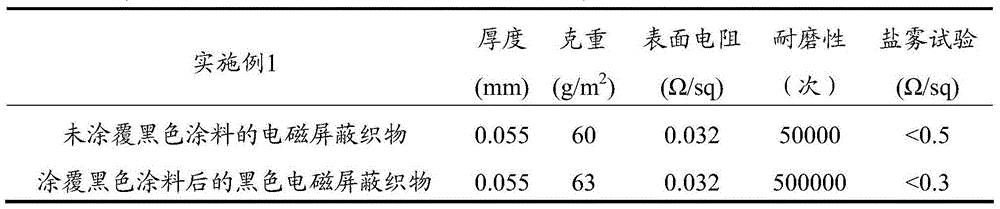

Black electromagnetic shielding fabric and preparation method thereof

The invention provides a black electromagnetic shielding fabric and a preparation method thereof. The preparation method comprises coating an electromagnetic shielding fabric with black paint and drying the paint at a temperature of 130 DEG C to obtain the black electromagnetic shielding fabric with a black coating, wherein the black paint contains a mixture of epoxy resin and polyimide resin, a curing agent and color paste. The surface of the electromagnetic shielding fabric is coated with epoxy resin and PI resin as paint so that a very thin and compact black coating is formed on the surface and thus the fabric has the advantages of the two types of resins. The resistance and thickness of the fabric basically are not changed, wear resistance, corrosion resistance and light absorption properties of the fabric are greatly improved and excellent electromagnetic shielding performances are obtained. The black electromagnetic shielding fabric has good decoration, taking, protection, delustring, shading, heat absorption and heat radiation performances and can be widely used for conductive clothes and adhesive tapes, conductive woven clothes, conductive non-woven fabrics and shielding liners.

Owner:ZHEJIANG SAINTYEAR ELECTRONICS TECH

Organic electroluminescence display device

ActiveCN100484356CDoes not reduce luminous efficiencyAchieve multi-color light emissionElectrical apparatusElectroluminescent light sourcesDisplay deviceLight reflection

The invention provides an organic EL display device, which has a substrate (11), and a first organic EL element part (10) and a second organic EL element part (20) juxtaposed on the same surface of the substrate; The EL element part (10) comprises at least a light-reflecting conductive layer (12), an organic light-emitting medium layer (13), and a transparent electrode layer (15) in order, and is formed on the organic light-emitting medium layer (13) or the transparent electrode layer (15) An element having a light reflective layer (14) inside or outside; the second organic EL element part (20) at least includes a light reflective conductive layer (12), a first inorganic compound layer (21), an organic luminescent medium layer ( 13), and a transparent electrode layer (15) and an element having a light reflection layer (14) inside or outside the organic luminescent medium layer (13) or the transparent electrode layer (15); from the first organic EL element part (10) The emission spectrum of the emitted light is different from that of the light emitted from the second organic EL element unit (20).

Owner:IDEMITSU KOSAN CO LTD

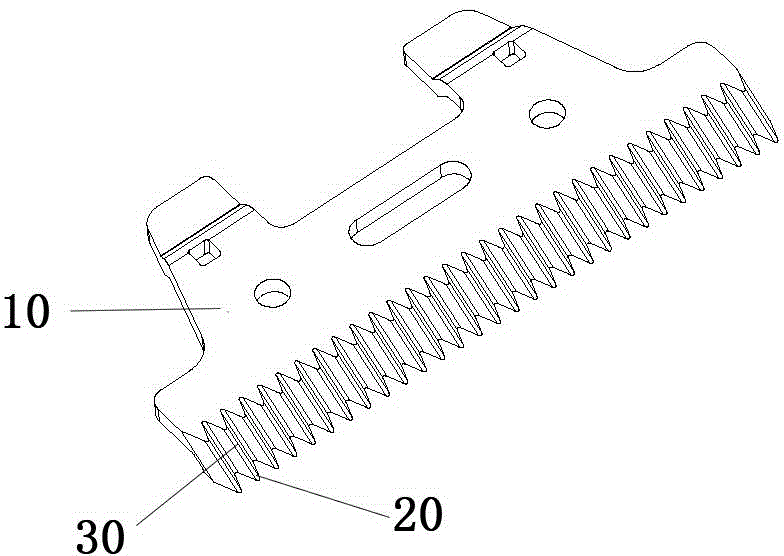

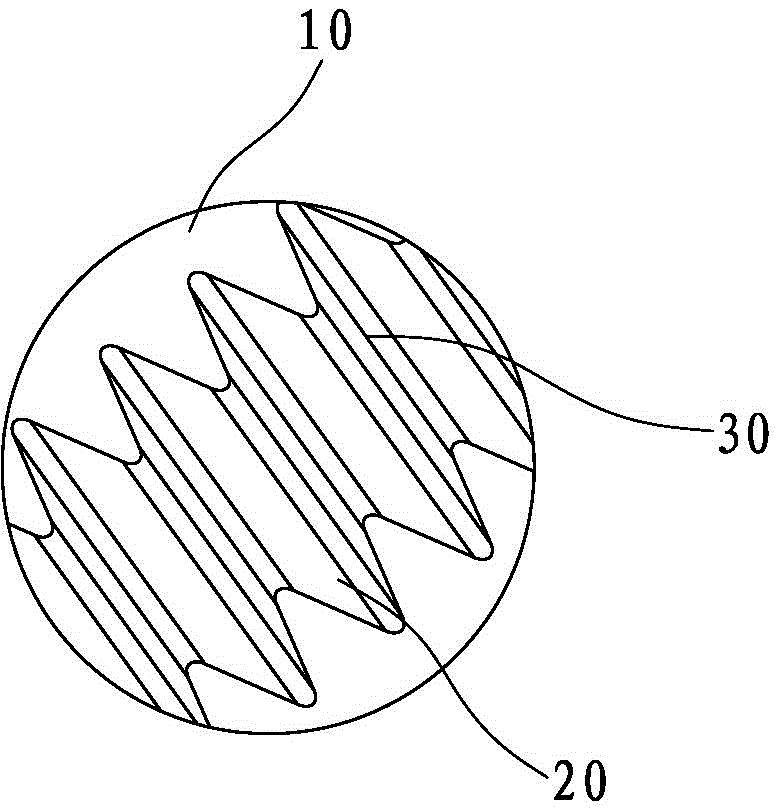

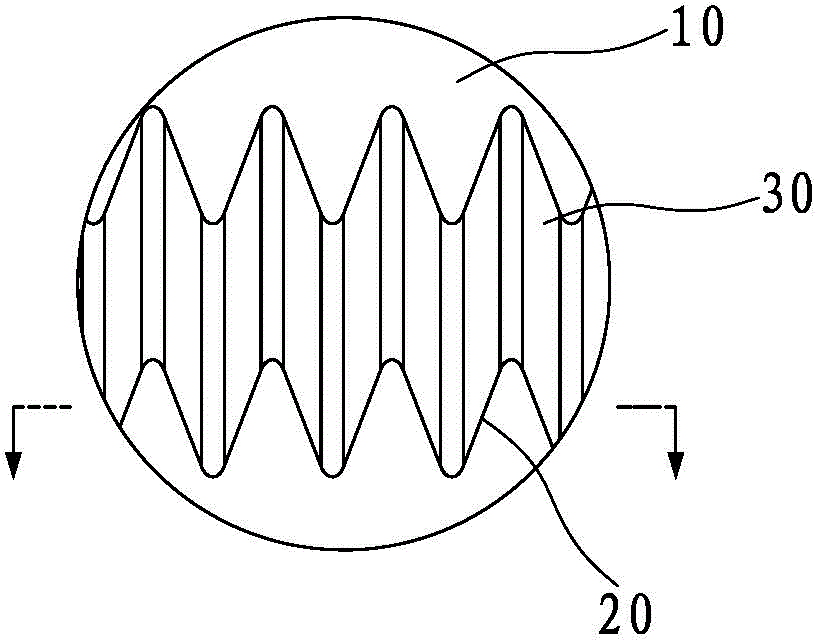

Blade structure formed in one time and machining method

ActiveCN104369203AIncrease the degreeImprove cutting efficiencyMetal working apparatusPowder metallurgyEngineering

The invention discloses a blade structure formed in one time. The blade structure formed in one time consists of a blade base body and blade teeth, wherein the front portion of the blade base body directly forms a triangular cone, one conical face of the triangular cone is connected with the front portion of the blade base body, the bottom face of the triangular cone and the other two conical faces form the blade teeth, and corner cuts on two sides of the blade teeth are formed between the two conical faces and the bottom face. A machining method comprises the steps of adopting a ceramic material, a powder metallurgy material or a precise casting material and the like to form the blade structure by means of a die. On the premise that the strength of the blade teeth is ensured, the corner cuts on the two sides of the blade teeth are decreased as far as possible, the sharpness of the blade teeth is improved, and the cutting efficiency is higher. In addition, the thickness of the blade base body of the blade structure is not changed, the strength of the whole blade is not influenced, and the service life of the blade is long.

Owner:XIAMEN LAIRY ELECTRIC APPLIANCES

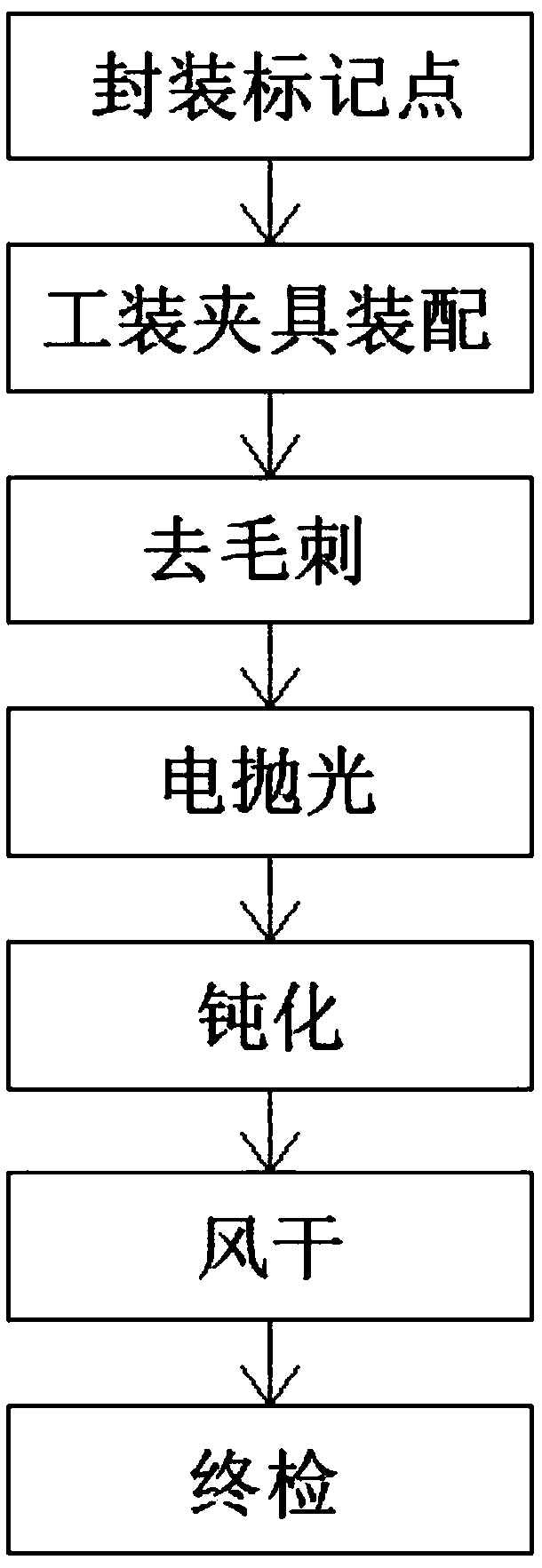

Micro-interval steel mesh template electric polishing technology

InactiveCN108866618AChange thicknessChange sizeMetallic material coating processesElectricitySolder paste

The invention discloses a micro-interval steel mesh template electric polishing technology. The micro-interval steel mesh template electric polishing technology comprises the steps that firstly, marking point packaging is conducted; secondly, tool clamp assembling is conducted; thirdly, deburring is conducted; fourthly, polishing is conducted; fifthly, passivation is conducted; and seventhly, final checking is conducted. The micro-interval steel mesh template electric polishing technology has the beneficial effects that the micro-interval steel mesh template electric polishing technology is provided, the hole wall burr point discharge and rapid dissolving principle is utilized, steel mesh template via hole wall burrs are sufficiently removed, sawteeth are flattened through cutting, and theeffect of smooth hole walls is achieved; and meanwhile, the hole size and the template thickness are not changed, printed solder paste is round and smooth, and the machining precision is improved while the machining difficulty is lowered.

Owner:光宏光电技术(深圳)有限公司

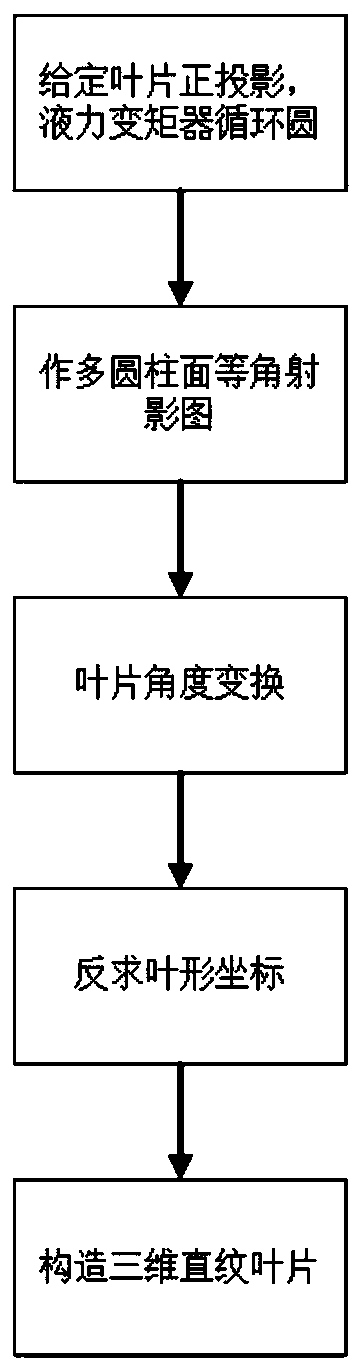

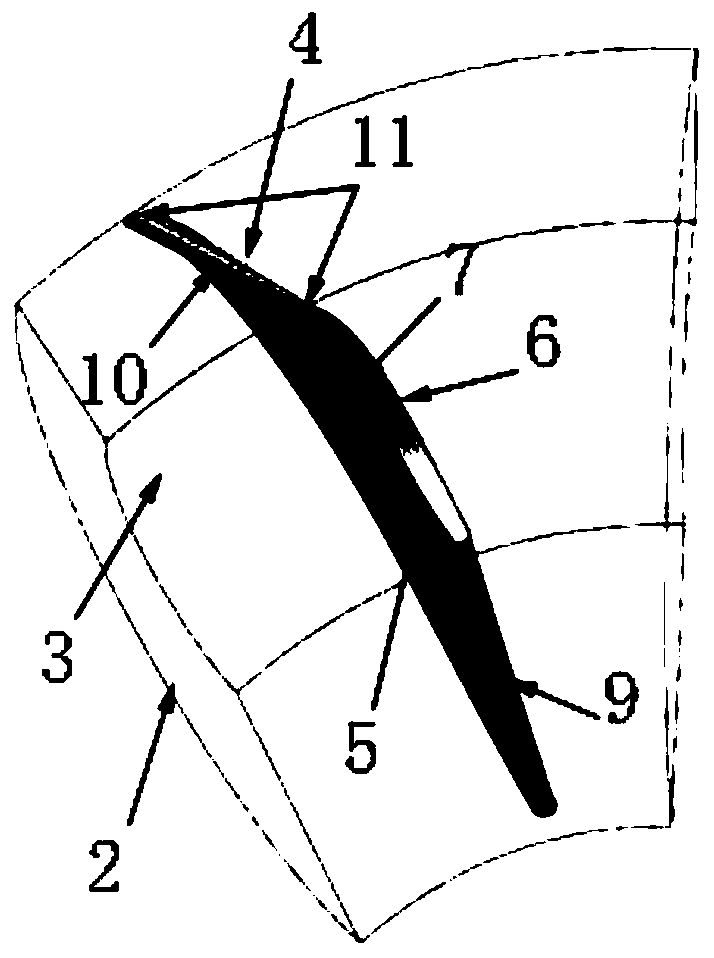

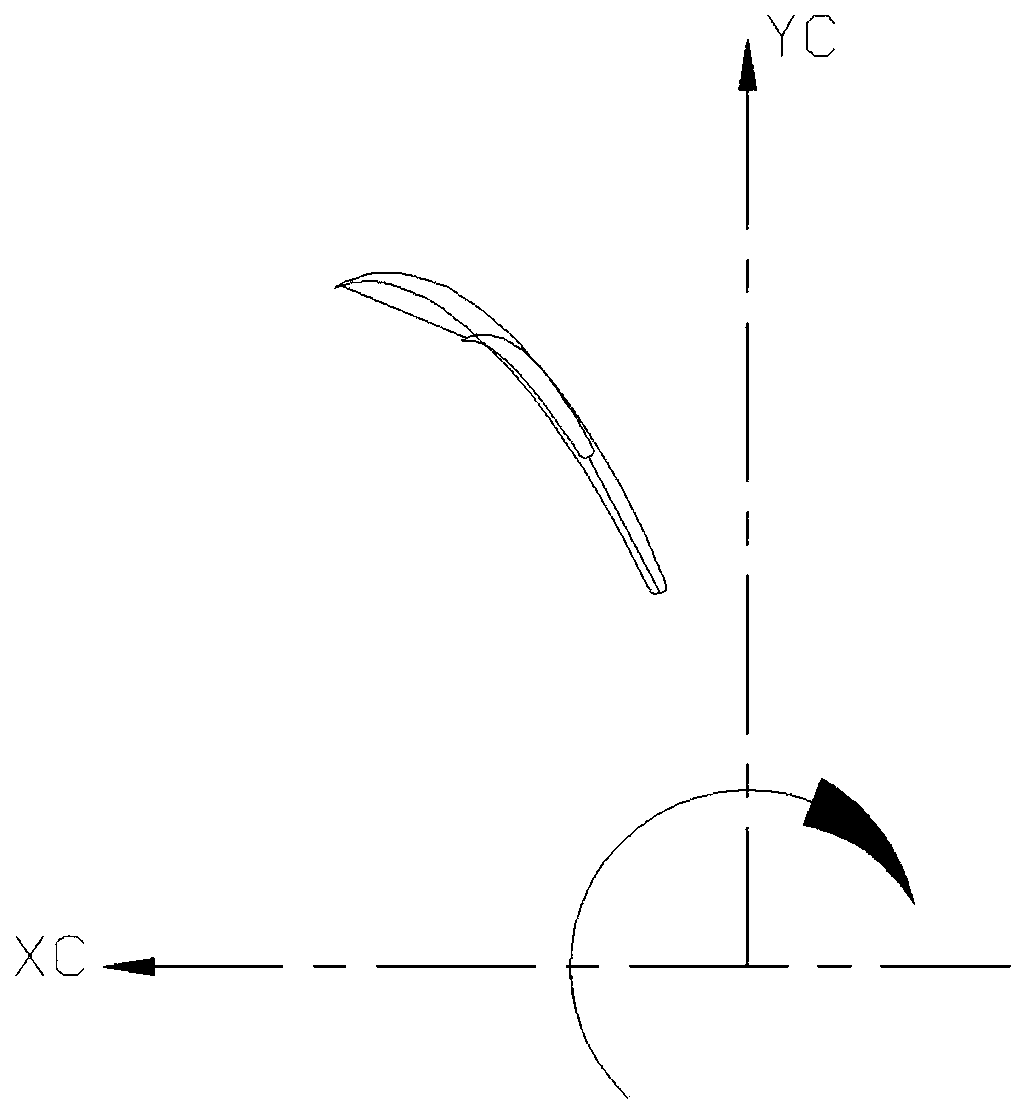

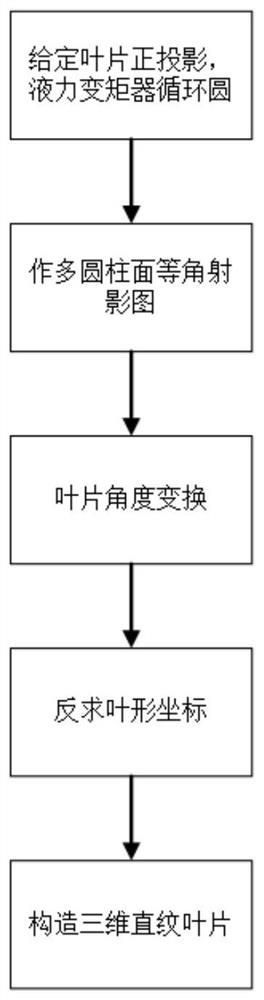

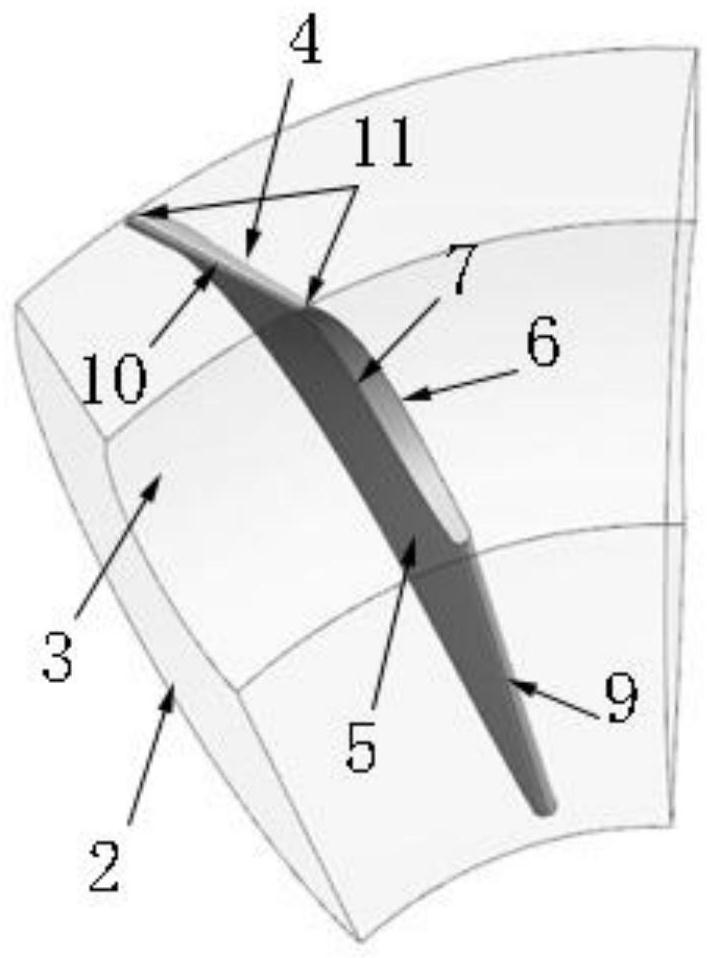

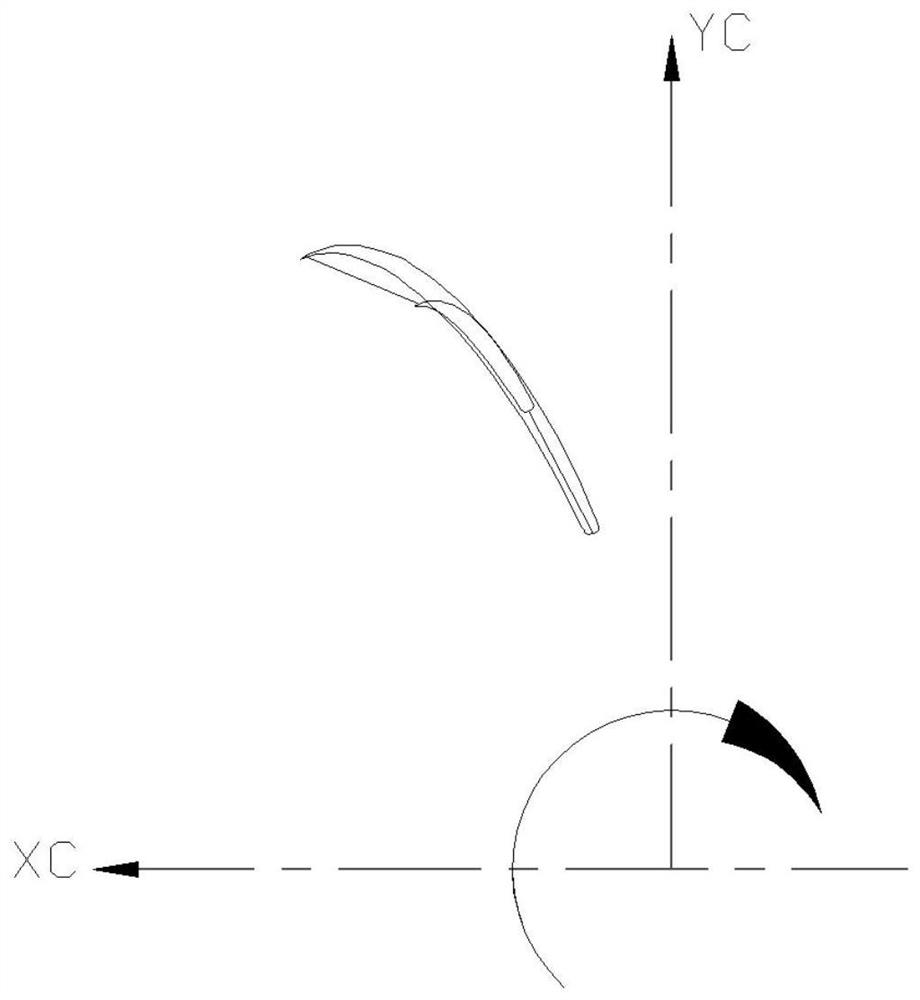

Hydraulic torque converter three-dimensional blade profile modification design method based on conformal transformation

ActiveCN110457815AChange thicknessGuaranteed closureDrawing from basic elementsHydro energy generationImpellerEngineering

The invention discloses a hydraulic torque converter three-dimensional blade profile modification design method based on conformal transformation, solves the problems that a traditional conformal transformation method is low in precision and serious in three-dimensional blade profile modification distortion, and belongs to the technical field of engineering machinery transmission. The method comprises: 1, giving orthographic projections of three impeller blades of the hydraulic torque converter and a circulating circle of the hydraulic torque converter; 2, finding a blade inlet and outlet sideboundary on the blade orthographic projection drawing; 3, drawing a blade curve multi-cylindrical-surface expansion diagram; 4, performing blade angle transformation, solving new blade coordinates, and obtaining a new blade space curve; and 5, sewing the blade space curve into a blade three-dimensional entity by constructing a ruled surface. According to the method provided by the invention, errors caused by traditional conformal transformation drawing can be greatly reduced, the defect of serious distortion caused by changing the angle of the blade in three dimensions is overcome, meanwhile,the precision of the shape of the head of the blade is ensured, and the defect of accumulative errors is avoided.

Owner:JILIN UNIV

Forming method of semiconductor structure

ActiveCN106033720ARepair unsaturated bondsQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureInterface layer

The invention provides a forming method of a semiconductor structure. The forming method includes the steps that a substrate is provided; an interface material layer is formed on the surface of the substrate through oxidation treatment; annealing treatment in an oxygen containing atmosphere is carried out on the interface material layer to form an interface layer, wherein the temperature of the annealing treatment is higher than that of the oxidation process; a dielectric layer is formed on the surface of the interface layer. By means of the method, the quality of the interface layer in the formed semiconductor structure can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Aluminum-plastic film and preparation method thereof

PendingCN112721354AImprove shrinkageIncreased shrinkage stressSynthetic resin layered productsLaminationPlastic filmPolypropylene

The invention provides an aluminum-plastic film and a preparation method thereof. The aluminum-plastic film comprises an aluminum foil layer, a first plastic layer and a second plastic layer. The first plastic layer is a multi-layer polypropylene layer, the multi-layer polypropylene layer comprises a corona layer, a heat-resistant layer and a heat-seal layer which are arranged in a stacked mode, the corona layer is arranged close to the aluminum foil layer, and the heat-seal layer is arranged away from the aluminum foil layer. The heat-resistant layer comprises a core layer and a coating layer coating the periphery of the core layer, and the core layer comprises a plurality of stress buffer strips which are arranged in an oriented manner and are arranged at intervals. The warping phenomenon of the aluminum-plastic film is more effectively improved or eliminated, the thickness of the original specification of the aluminum-plastic film is not changed, and the influence on forming, heat sealing and other properties is smaller.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

Ion exchange membrane for ultra-high current density oxygen cathode electrolysis and preparation method thereof

ActiveCN103556178BHigh mechanical strengthIncreased electrochemical fluxOrganic diaphragmsHigh current densityComposite film

The invention relates to an ion exchange membrane for superhigh-current-density oxygen cathode electrolysis and a preparation method thereof. The ion exchange membrane is a multilayer composite film composed of a perfluorocarboxylic acid ion exchange resin layer, a carbon-nanotube-containing perfluorosulfonic acid ion exchange resin layer, a reinforcing mesh, a sulfonic acid side gas release coating and a carboxylic acid side multifunctional coating, wherein the total thickness of the basal membrane of the perfluorinated ion exchange membrane is 90-180 micrometers, the thickness of the perfluorosulfonic acid resin layer is 80-160 micrometers, the thickness of the perfluorocarboxylic acid resin layer is 8-16 micrometer, and the thickness of the two side surface coatings of the membrane is respectively 3-12 micrometers. The membrane can be prepared by a melt coextrusion or multilayer hot-press compounding technique. The membrane is used for an oxygen cathode electrolysis technique, is especially suitable for ion-exchange-membrane-process caustic soda production by a superhigh-current-density oxygen cathode electrolysis technique, and has favorable mechanical properties and electrochemical properties.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

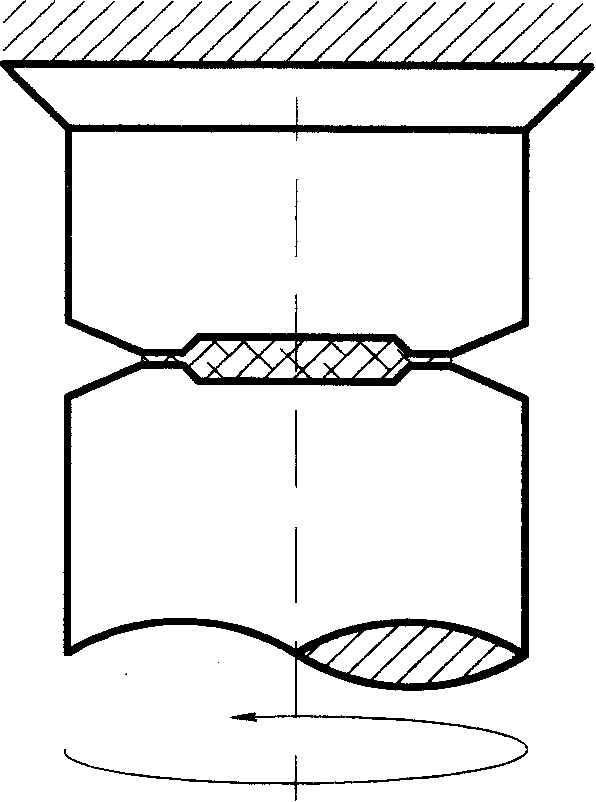

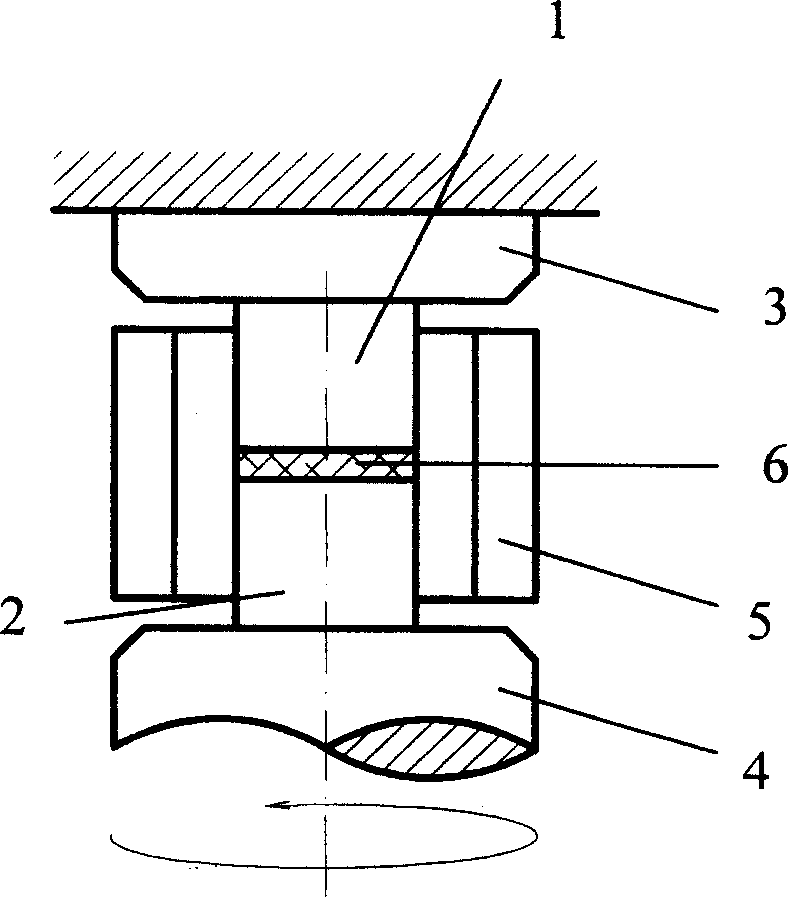

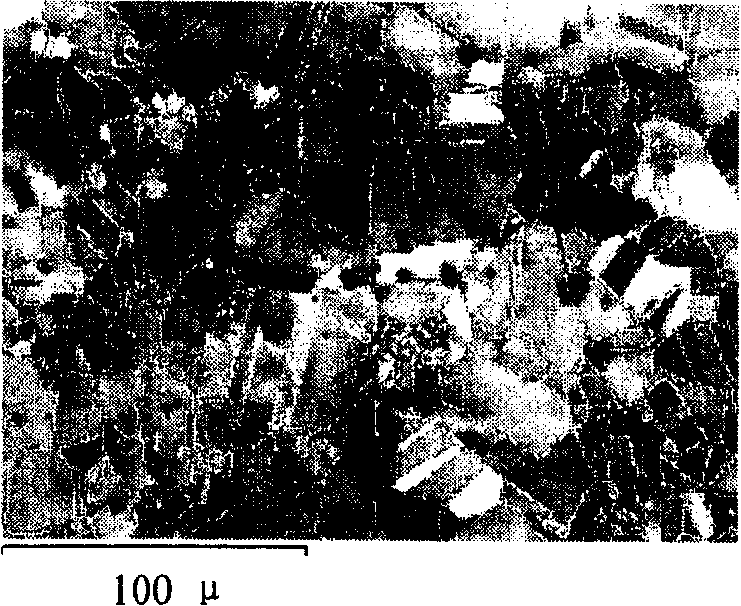

High pressure torsion test method capable of fining sample grain

InactiveCN100392373CImprove carrying capacityNo change in thicknessPreparing sample for investigationInterference fitExperimental methods

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

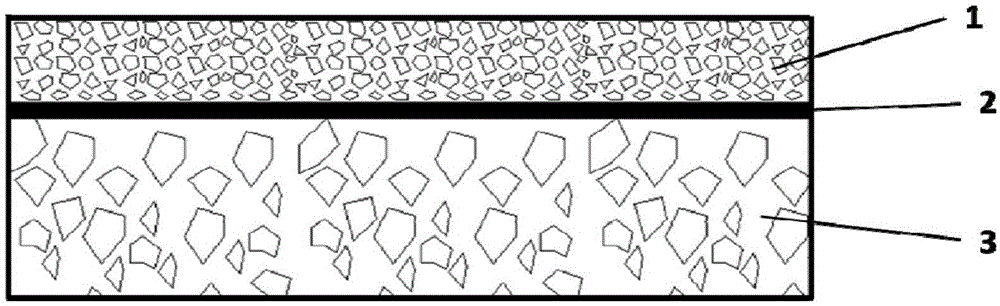

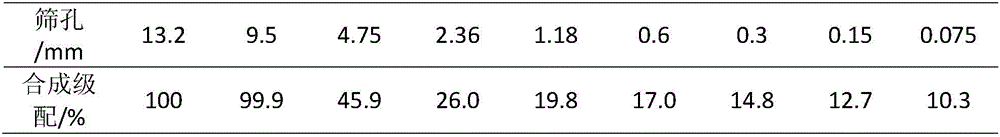

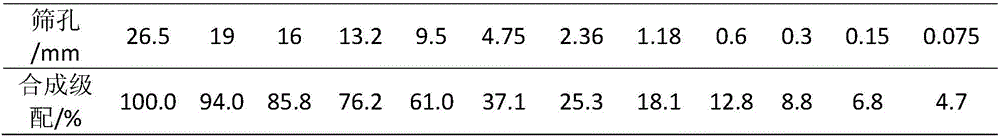

Asphalt surface layer structure of highway

The present invention relates to an asphalt surface layer structure of a highway. The structure is composed of an ultra-thin wearing layer having the thickness of 2-3cm and an intermediate layer having the thickness of 7-8cm. The ultra-thin wearing layer and the intermediate layer are well bonded. Compared with the traditional surface layer structure, the novel surface layer combination can maintain the good performance, as the thickness is smaller, the cost is lower, maintenance and repairing are convenient, and the long life cycle benefit is good.

Owner:TONGJI UNIV +1

Method for improving glass-to-glass full-fitting warping

The invention discloses a method for improving glass-to-glass full-fitting warping, belonging to the technical field of stereo display, and aiming to solve the problem of warping in a glass-to-glass fitting technology. The scheme comprises two methods. The first method comprises the following steps: before the glass-to-glass fitting operation, peeling off an upper polaroid, and fitting the surfaces of optical glass and C / F glass with optical cement; after the cement is cured, pasting the upper polaroid back to the outer surface of the optical glass; and finally pasting a grating to the outer surface of the upper polaroid to complete the whole glass-to-glass fitting process. The second method comprises the following steps: before the glass-to-glass fitting operation, peeling off the upper polaroid, and fitting the surfaces of optical glass and C / F glass with optical cement; after the cement is cured, pasting the grating to the outer surface of the optical glass, and finally pasting the upper polaroid back to the outer surface of the grating to complete the whole glass-to-glass fitting process.

Owner:NINGBO VISION DISPLAY TECH

Electric contact point and contact element

ActiveCN105453206AEnsure joint strengthGuaranteed mechanical strengthContact materialsEngineeringContact element

[Problem] An arcing horn, or the like, for guiding an arc occurring when opening / closing an electric contact thereby preventing erosion of the contact point or a support material, or, a protruding portion of the support material provided at an extremity portion of the contact point in the direction in which the arc is driven thereby rendering the contact point difficult to melt, are known ways in prior art to prevent detachment and erosion. However, as these methods are only realizable if sufficient space can be secured for an arc-extinguishing chamber, or if sufficient dimensions of the support material can be secured, these methods are not necessarily adoptable if a device is to be reduced in size. [Solution] The present invention is characterized in that an electric contact point and a contact element having improved resistance to erosion are achieved by a reduction in the amount of erosion at the electric contact point, comprising pasting onto the surface of a pure silver layer on the back side of a contact point where detachment and erosion readily progress, a copper or a copper alloy having excellent electric conductivity, heat conductivity and mechanical strength as a functional layer, thereby conferring to the functional layer a function of transmitting to a support material the heat generated when opening / closing the electric contact, a function of shortening the duration of chattering, and a function of preventing detachment and erosion, or the like, by maintaining the strength of the bond with the support material.

Owner:TOKURIKI HONTEN

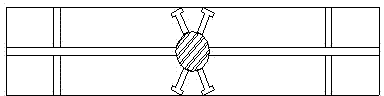

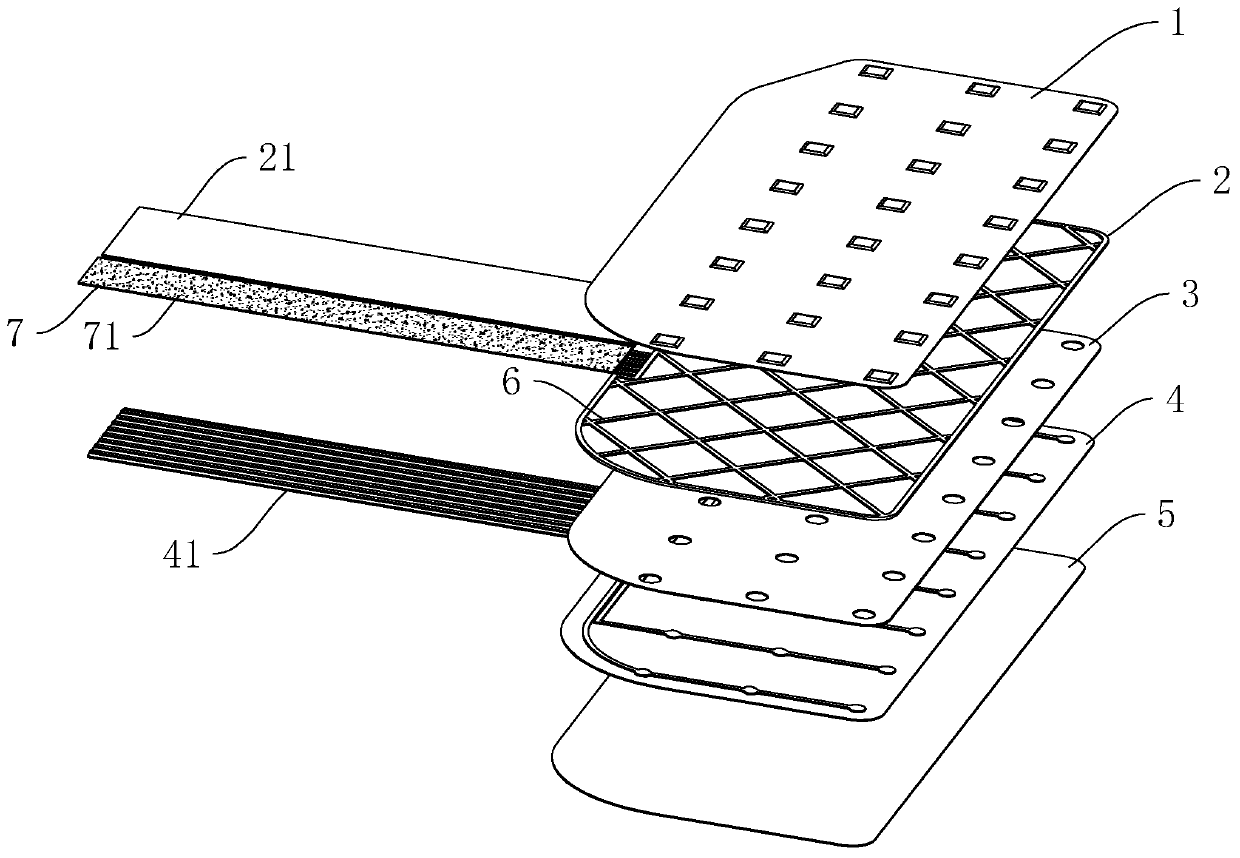

Anti-static thin-film switch and manufacturing method thereof

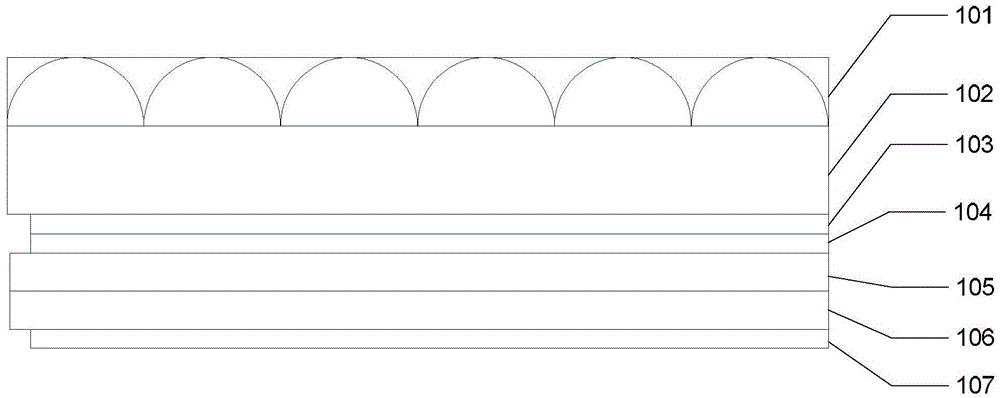

PendingCN110544595AWith anti-static functionNo change in thicknessElectric switchesEmergency connectionsSilver pasteElectronic switch

The invention discloses an anti-static thin-film switch and a manufacturing method thereof, and belongs to the technical field of electronic switches. According to the technical scheme, the main points are that the switch comprises a panel, an upper circuit layer, an isolation layer, a lower circuit layer and a primer layer which are sequentially arranged from top to bottom; all the layers are adhered into a whole through glue layers. The switch is characterized in that a latticed conductive silver paste layer is printed at one side, facing the panel layer, of the upper circuit layer, and a static lead-out wire is led out from one end of the conductive silver paste layer and grounded. The invention has the advantages that the anti-static function is added on the basis that the thickness ofan original thin-film switch is not changed basically, and the static release stability is guaranteed.

Owner:厦门铭彩电子科技有限公司

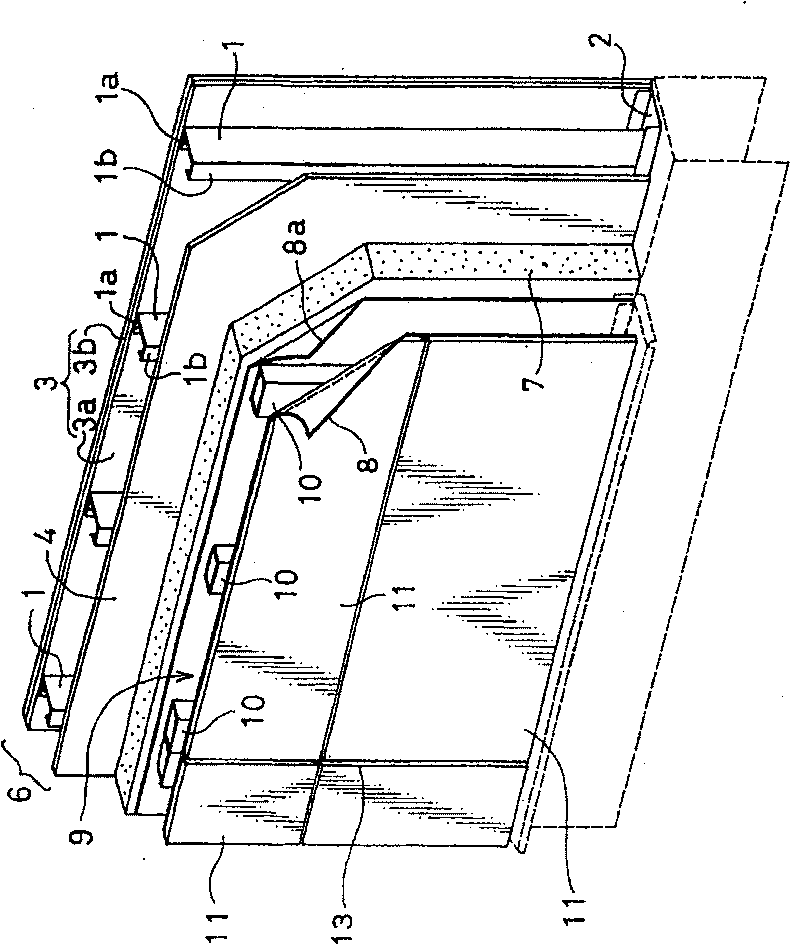

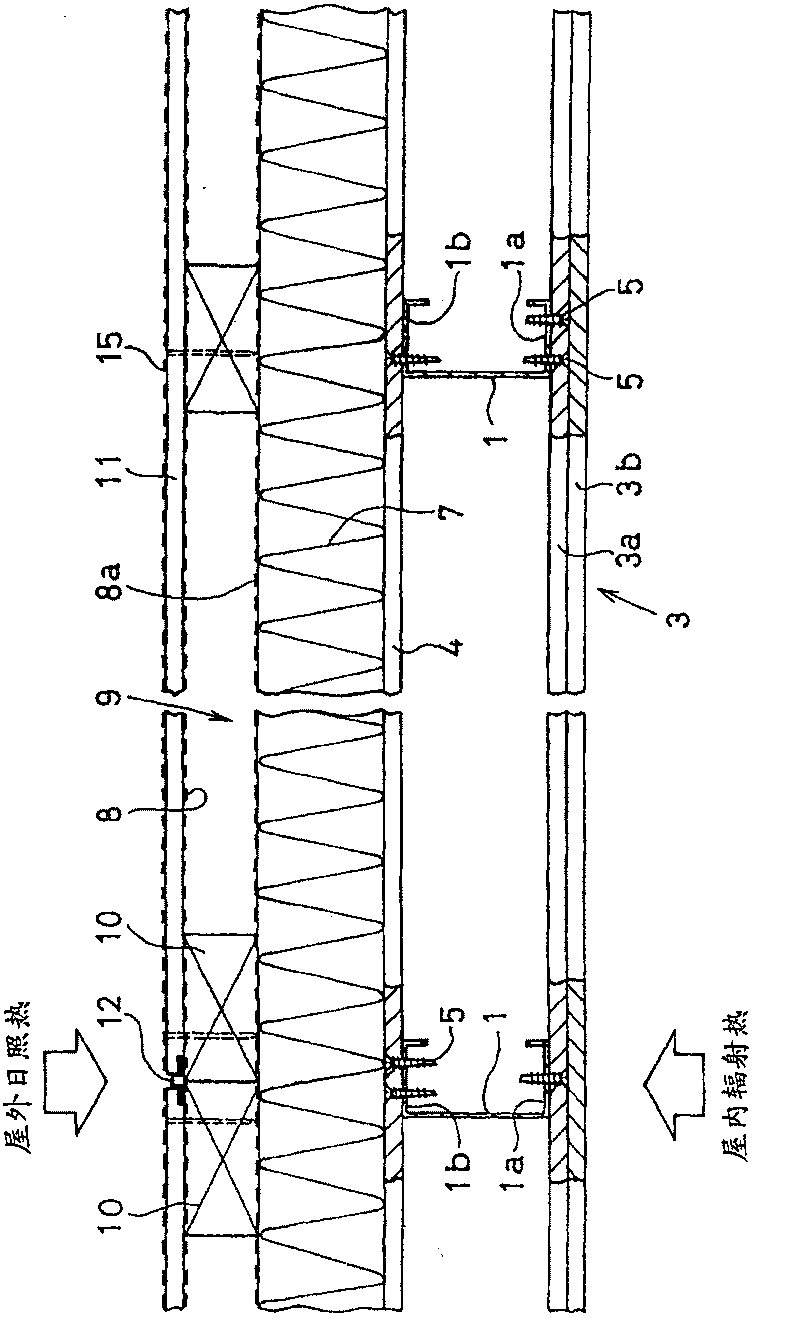

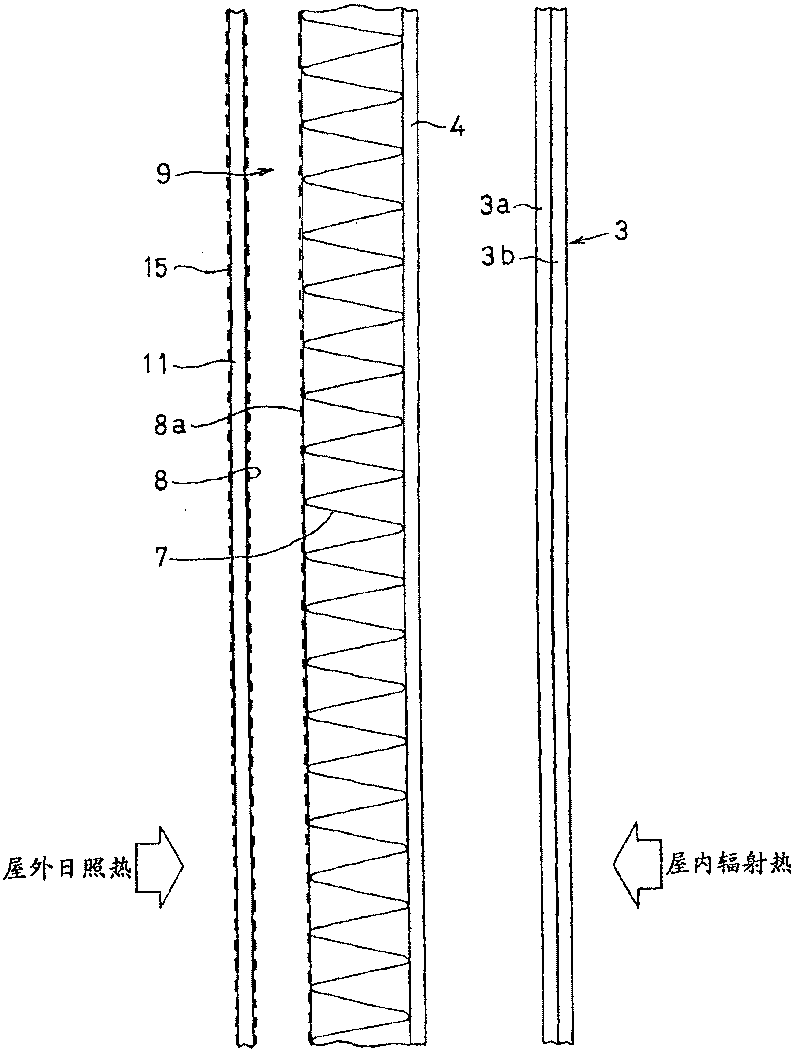

Structure of external wall or roof and external material for external wall or roofing materia

InactiveCN1981105BNo change in thicknessIncrease reflectionRoof covering insulationsMechanical engineeringPhysics

A structure of an external wall or a roof and an external material for the external wall or a roofing material. In the structure of the external wall or the roof of a building, heat insulating and heat shielding performances are provided to a permeable layer for which dehumidifying action by the circulation of air was expected to secure high heat insulating and heat shielding performances for theexternal wall or the roof without changing the thickness of an insulator. Accordingly, when the heat insulating and heat shielding performances must not be changed, the thickness of the insulator canbe reduced less than before. The building in which an external material (11) is installed through the permeable layer (9) installed on the outside of the structure of the external wall or the roof ischaracterized in that low heat radiating sheets (8, 8a) having a low radiating performance against the heat radiation of long wavelength components are installed on the permeable layer (9) side surfaces of one or both of the external material (11) and the insulator (7).

Owner:NIPPON STEEL CORP +1

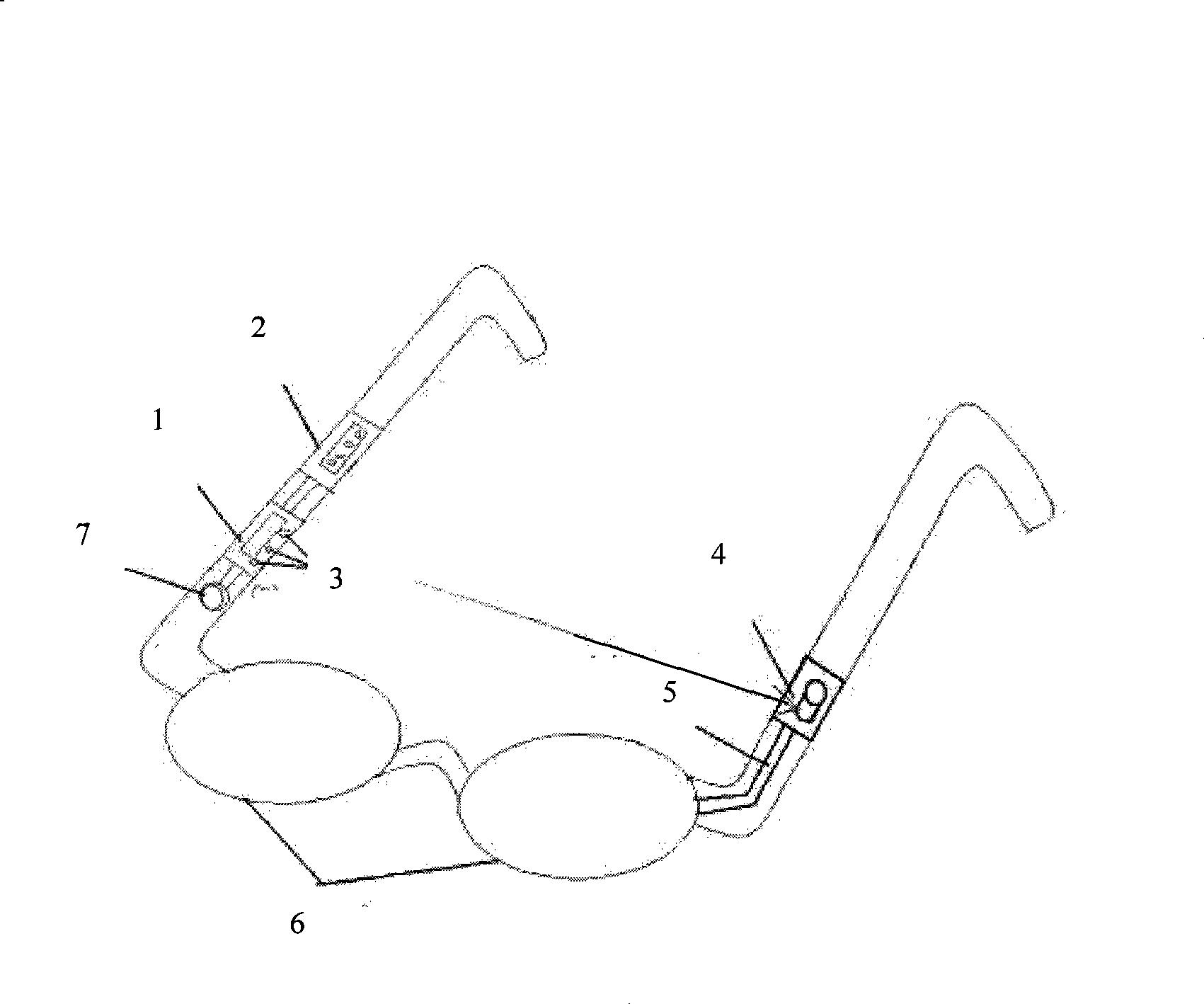

Glasses capable of regulating degree automatically

InactiveCN101446692AShorten the timeChange thicknessNon-optical adjunctsOptical partsMicrocomputerUses eyeglasses

The invention relates to glasses capable of regulating degree automatically. The glasses comprise a shelf, a frame and eyeglasses. The glasses also comprise an eye degree detector, a microcomputer database, an infrared scanning device, a degree regulator, a degree adjutage and a regulating button. The eyeglasses are intelligent eyeglasses. The regulating button is connected with the eye degree detector which is connected with the microcomputer database. The degree regulator is connected with the degree adjutage. The eye degree detector is started by the regulating button and detects the actual degree of eyes by utilizing the infrared scanning device. The degree data is input into the microcomputer database and sent to the degree regulator after the degree data is collected. The data enters the intelligent eyeglasses by the degree adjutage, and the degree of the intelligent eyeglasses is regulated. Compared with the prior art, the glasses capable of regulating degree automatically has the advantages of time saving, convenience, light weight, etc.

Owner:上海市复旦中学

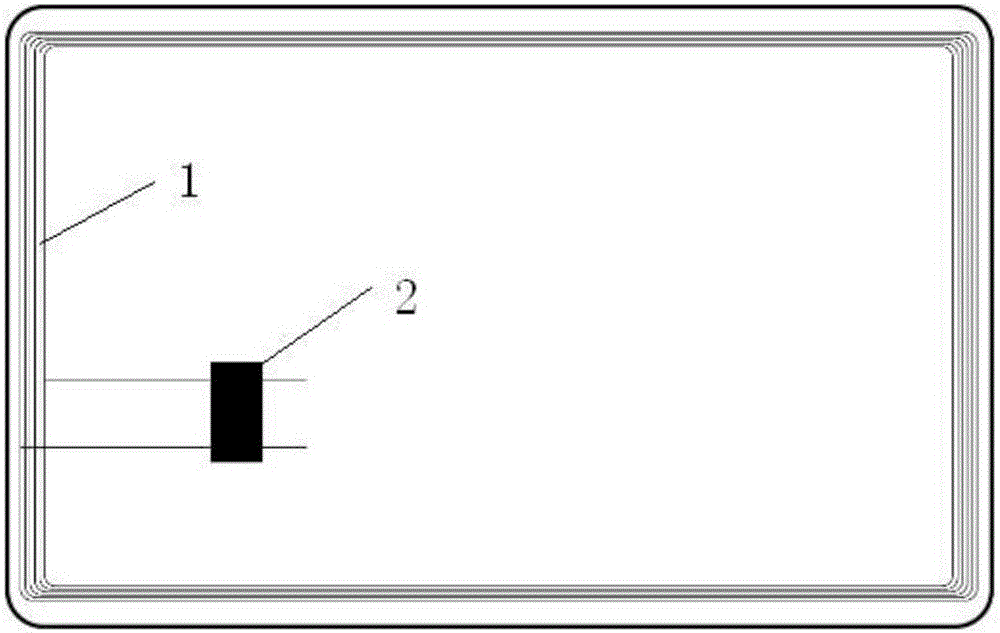

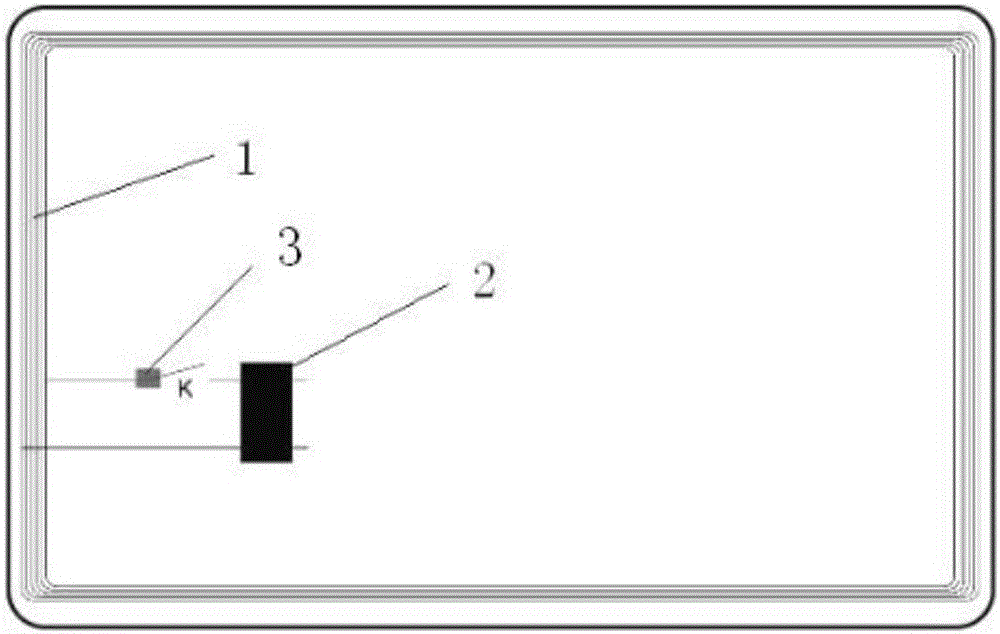

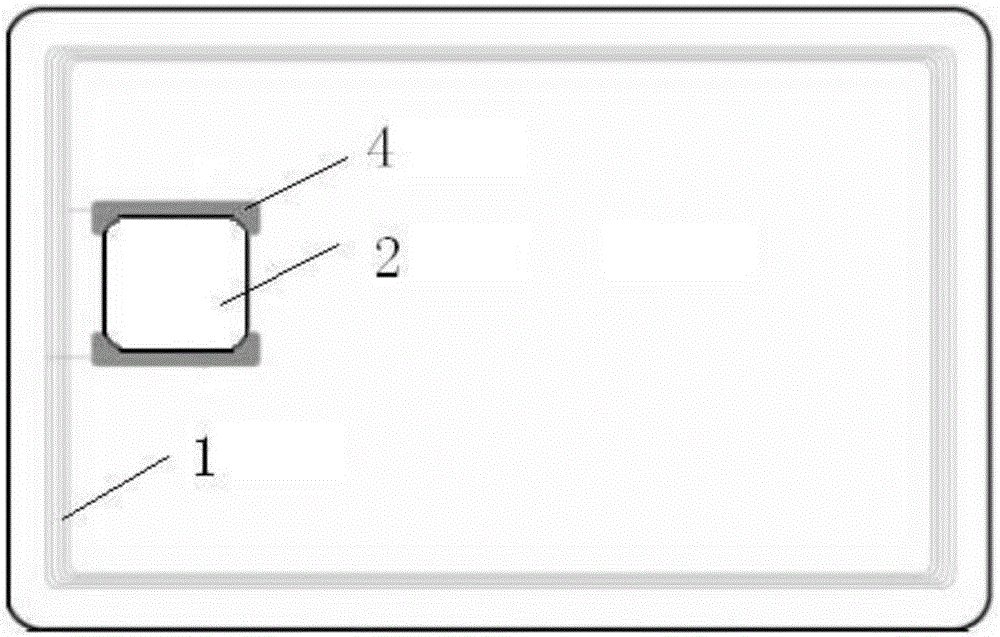

Contactless smart card with security protection function and security protection method thereof

InactiveCN105787393AProtect the safety of useProtection securityInternal/peripheral component protectionRecord carriers used with machinesEngineeringContactless smart card

The invention discloses a contactless smart card with a security protection function and a security protection method thereof.The contactless smart card comprises a first card face layer, a second card face layer and a circuit board layer embedded between the first card face layer and the second card face layer.The circuit board layer comprises a smart chip and a coil.The smart chip is electrically connected with the coil.The contactless smart card further comprises a light-dependent control element, and the light-dependent control element is connected with the coil in parallel or arranged inside the smart chip.The light-dependent control element is additionally arranged in the coil or the chip of the contactless smart card to smartly control the contactless smart card, information of the smart card is prevented from being stolen, and the security of the smart card is protected.Meanwhile, the thickness of the smart card is not changed, products such as a shielding sleeve and a shielding card are not additionally increased, and the effects of effectively reducing cost and being convenient to operate are achieved.

Owner:HIERSTAR SUZHOU

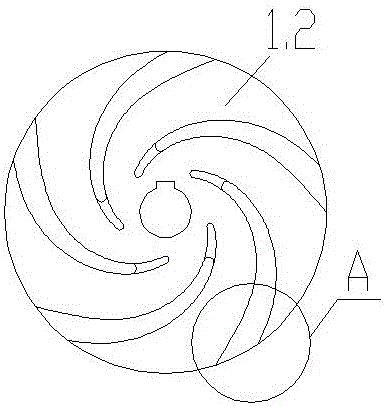

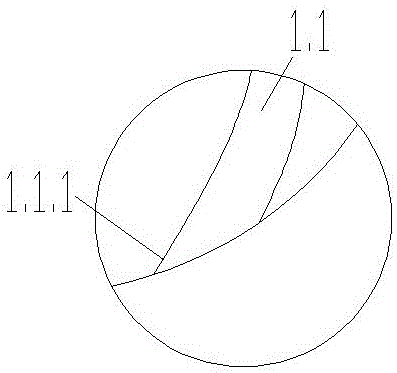

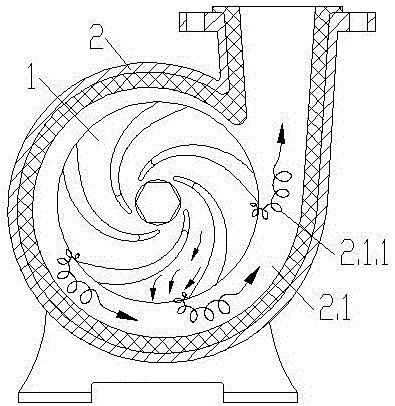

Plastic centrifugal pump

ActiveCN106402017ANo change in thicknessNo change in intensityPump componentsPumpsReverse currentEngineering

The invention discloses a plastic centrifugal pump. The plastic centrifugal pump comprises a pump shell, a main shaft, a shaft seal on the main shaft, a bearing base, and an impeller mounted at the end part of the main shaft and positioned in a volute cavity of the pump shell; the impeller includes an impeller spoke plate, and an impeller blade on the impeller spoke plate; and the inner bending side incision of the tail part of the impeller blade is provided with an inclined guide angle for increasing the flowing angle of a fluid thrown out from a liquid outlet of an impeller runner to forwards flow the fluid in the direction of the liquid outlet of the impeller runner. The thickness and the intensity of the plastic impeller blade are not changed, and the form of the tail part of the impeller blade is only changed, so that the moving direction of the fluid is changed, the generation or / and increment of an eddy current area, a reverse current area and a slow flowing area in a pump cavity is reduced, the convection impact of the fluid is reduced, and the efficiency of the pump is promoted.

Owner:宜兴市宙斯泵业有限公司

Method of three-dimensional vane modification design of torque converter based on conformal transformation

ActiveCN110457815BNo change in thicknessGuaranteed closureGeometric CADDrawing from basic elementsImpellerTransmission technology

The invention discloses a three-dimensional vane shape modification design method of a hydraulic torque converter based on conformal transformation, which solves the problems of low precision and serious distortion of three-dimensional vane modification of the traditional conformal transformation method, and belongs to the transmission technology of construction machinery. field. The method provided by the invention includes: step 1: giving the orthographic projection of the three impeller blades of the hydraulic torque converter and the circulating circle of the hydraulic torque converter; step 2: finding the edge of the inlet and outlet of the blade on the orthographic projection of the blade; step 3: Make a multi-cylindrical expansion diagram of the blade curve; Step 4: Transform the blade angle, find the coordinates of the new blade, and obtain a new blade space curve; Step 5: The blade space curve is stitched into a three-dimensional blade entity by constructing a ruled surface. The method provided by the invention can greatly reduce the error caused by the traditional conformal transformation mapping, solve the disadvantage of serious distortion of the blade angle in three-dimensional change, and at the same time ensure the accuracy of the shape of the blade head without the disadvantage of accumulating errors.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com