Asphalt surface layer structure of highway

An asphalt surface layer and highway technology, applied in the field of asphalt pavement structure, can solve the problems of high maintenance cost, large thickness of milling and hood, and high road operating cost, so as to reduce engineering cost, ensure anti-rutting performance and good service performance. and the effect of economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

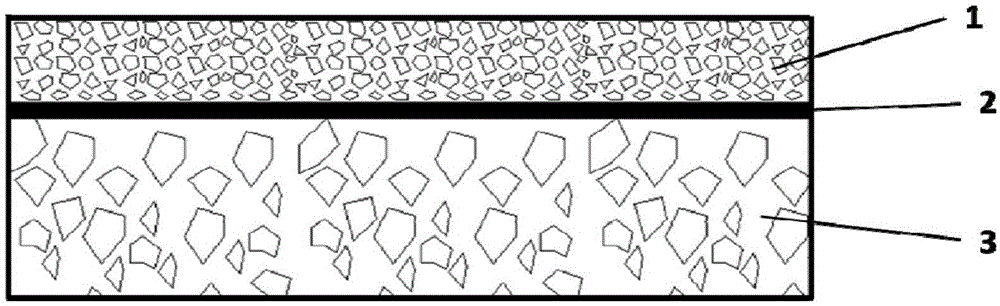

[0016] A kind of 2.5+7.5 novel expressway surface structure combination provided by the present invention, its structure is as follows figure 1 As shown, the structure includes an ultra-thin wear layer 1, an adhesive layer 2, and a middle surface layer 3 from top to bottom.

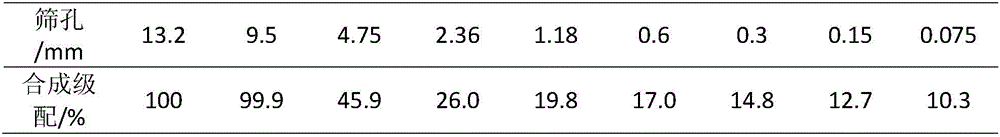

[0017] Ultra-thin wear layer 1 is designed to have a thickness of 2.5cm, using SMA-10 mixture, SBS modified asphalt, and the mass ratio of each grade of mineral material is 5-10mm diabase: 3-5mm diabase: 0-3 limestone: limestone ore Flour = 68:3:19:10, oil-stone ratio 6.4%, lignin fiber content 0.3% (external mixing). The synthetic gradation of SMA-10 is as follows:

[0018] Table 1 Synthetic gradation of SMA‐10

[0019]

[0020] Adhesive layer 2 adopts SBS modified emulsified asphalt, and the spreading amount is 0.5kg / m2.

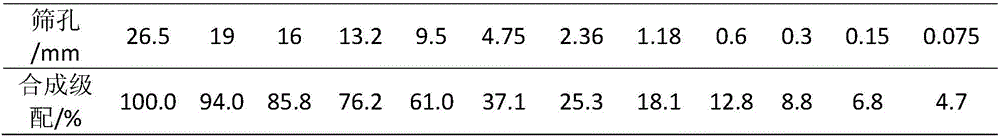

[0021] The design thickness of the middle surface layer 3 is 7.5cm, using AC-20 mixture, SBS modified asphalt, and the mass ratio of each grade of mineral material is 10-20mm li...

Embodiment 2

[0036] An expressway asphalt pavement structure is composed of an ultra-thin wear layer with a thickness of 2cm and an intermediate layer with a thickness of 8cm, and modified emulsified asphalt adhesive layer oil is sprayed between the ultra-thin wear layer and the intermediate layer.

[0037] The maximum nominal particle size of the ultra-thin wearing layer mixture is 9.5mm, and the raw material for the mixture is made of modified asphalt, coarse aggregate, fine aggregate, and filler in a weight ratio of 4:42:16:4. Among them, the modified asphalt is SBS polymer modified asphalt, the coarse aggregate is basalt with a particle size of 5 mm and 3 mm, the fine aggregate is limestone machine-made sand with a particle size of less than 3 mm, and the filler is mineral powder obtained by grinding limestone.

[0038] The maximum nominal particle size of the mixture in the middle layer is 19mm. The raw materials for the mixture are modified asphalt, coarse aggregate, fine aggregate an...

Embodiment 3

[0040] An expressway asphalt pavement structure is composed of an ultra-thin wearing layer with a thickness of 3 cm and an intermediate layer with a thickness of 7 cm, and modified emulsified asphalt adhesive layer oil is sprayed between the ultra-thin wearing layer and the intermediate layer.

[0041] The maximum nominal particle size of the ultra-thin wear layer mixture is 9.5mm, and the raw material for the mixture is made of modified asphalt, coarse aggregate, fine aggregate, and filler in a weight ratio of 7:80:54:13. Among them, the modified asphalt is SBS polymer modified asphalt, the coarse aggregate is basalt with a particle size of 10mm and 5mm, the fine aggregate is limestone machine-made sand with a particle size of less than 3mm, and the filler is strong basic rock hydrophobic stone after grinding Fine mineral powder obtained.

[0042] The maximum nominal particle size of the mixture in the middle layer is 19mm. The raw materials for the mixture are modified aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum nominal particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com