Paper historical relic deacidifying and reinforcing protective material and preparation method thereof

A technology for protecting materials and history, applied in the field of deacidification and reinforcement of paper historical cultural relics and their preparation, can solve the problems of treatment effect and treatment efficiency, poor operability, high temperature softening, etc. The effect of simple application and preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

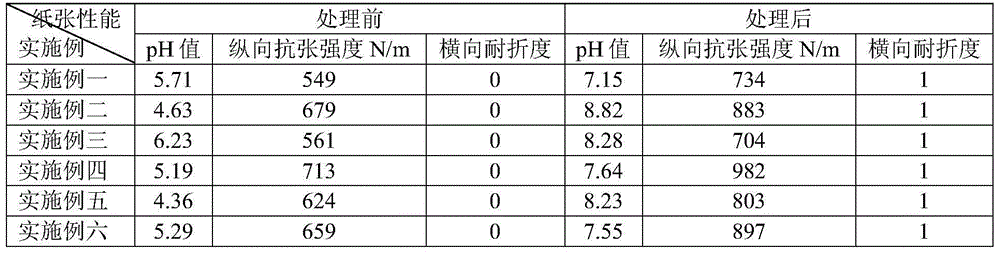

Examples

Embodiment 1

[0042] In this embodiment, a method for preparing a paper-based historical relic deacidification and reinforcement protection material, the steps are as follows:

[0043] (1) under 60 ℃ of constant temperature water baths, in 100g organic solvent (according to weight ratio glycerol: the mixture of ethanol=1: 3), add 6g calcium bicarbonate and 0.5g starch, stir 15min with 600r / min speed, Then reduce the speed to 300r / min, add 70g deionized water while stirring, and stir for 10min to obtain a mixed solution;

[0044] (2) After the obtained mixed solution was ultrasonically oscillated for 20 minutes, 200 g of the above-mentioned organic solvent was added, and ultrasonically treated for 20 minutes, and then cooled to room temperature to obtain a uniform and translucent paper historical relic deacidification and reinforcement protection material.

Embodiment 2

[0046] In this embodiment, a method for preparing a paper-based historical relic deacidification and reinforcement protection material, the steps are as follows:

[0047] (1) Add 11g of magnesium ethylate and 0.5g of hydroxypropyl methylcellulose to 100g of ethanol in a constant temperature water bath at 70°C, stir at 700r / min for 20min, then reduce the speed to 400r / min, and add 90g deionized water was stirred for 15min to obtain a mixed solution;

[0048] (2) After the obtained mixed solution was ultrasonically oscillated for 20 minutes, 200 g of ethanol was added, and then ultrasonically treated for 25 minutes, cooled to room temperature, and a uniform, translucent paper-based historical relic deacidification and reinforcement protection material was obtained.

Embodiment 3

[0050] In this embodiment, a method for preparing a paper-based historical relic deacidification and reinforcement protection material, the steps are as follows:

[0051] (1) In 100g of organic solvent (according to weight ratio propanol: ethylene glycol = 1: 1 mixture) in 80 ℃ constant temperature water bath, add 3g of magnesium bicarbonate and 0.1g of hydroxyethyl cellulose, with 800r / Stir at min speed for 20 min, then reduce the speed to 500r / min, add 50g of deionized water while stirring, and stir for 15 min to obtain a mixed solution;

[0052] (2) After the obtained mixed solution was ultrasonically oscillated for 35 minutes, 200 g of the above-mentioned organic solvent was added, and ultrasonically treated for 10 minutes, and cooled to room temperature to obtain a uniform and translucent paper-based historical relic deacidification and reinforcement protection material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com