Black electromagnetic shielding fabric and preparation method thereof

An electromagnetic shielding and fabric technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of poor corrosion resistance and friction resistance of electromagnetic shielding fabrics, poor shading performance of electromagnetic shielding fabrics, light absorption performance and friction resistance of electromagnetic shielding materials Poor corrosion resistance and other problems, to achieve good decorative performance and shading performance, excellent electromagnetic shielding performance, and improve the effect of friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

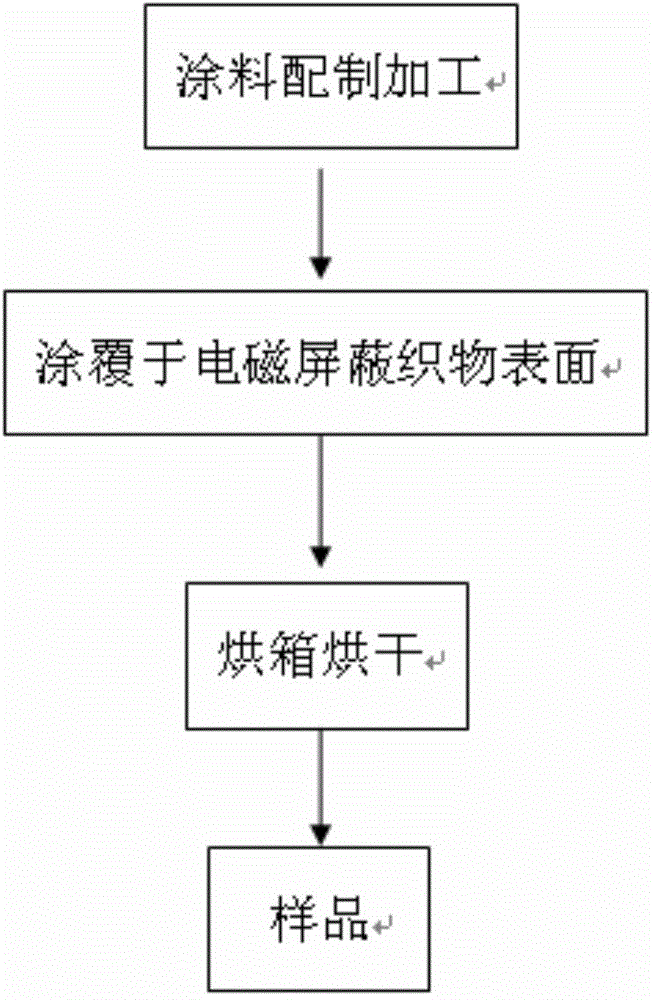

[0038] Correspondingly, the present invention provides a kind of preparation method of black electromagnetic shielding fabric, comprises the following steps:

[0039] Coating the black paint on the electromagnetic shielding fabric, and then drying it above 130°C to obtain a black electromagnetic shielding fabric compounded with a black coating;

[0040] The black paint comprises: a mixture of epoxy resin and polyimide resin, curing agent and color paste.

[0041] The present invention mainly carries out the blackening process to the electromagnetic shielding fabric, and forms a black coating on the surface by coating a black paint. Since the thickness of the black coating formed by coating is extremely thin and dense, the thickness of the electromagnetic shielding fabric does not change, and the black coating The resulting electromagnetic shielding fabric has excellent electrical conductivity, and also has good wear resistance, corrosion resistance and light absorption perform...

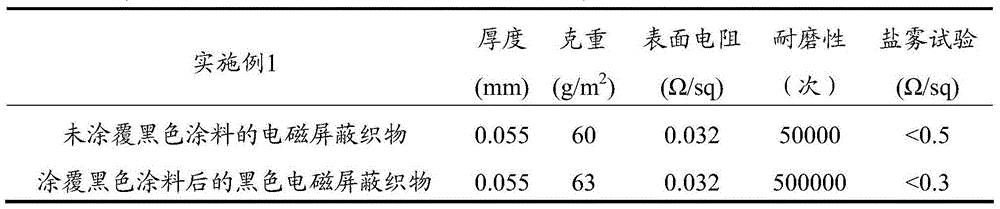

Embodiment 1

[0051] Be 1:1 according to mass ratio, epoxy resin and PI resin are mixed, obtain the mixture of epoxy resin and PI resin; Get 20g described mixture, mix it and 0.2g curing agent and 4g color paste at room temperature, and Stir thoroughly for 5 minutes to prepare a black paint.

[0052] The electromagnetic shielding fabric is a PF36B product produced by Sanyuan Electronic Technology Co., Ltd.; the black paint is evenly coated on the electromagnetic shielding fabric, and the coating amount is 10g / cm 2 , and then dried at 130° C. to obtain a black electromagnetic shielding fabric sample compounded with a dense and uniform black coating.

[0053] According to the method described above, the wear resistance and corrosion resistance tests of the samples were carried out, and the results are shown in Table 1. Table 1 shows the main performance results of the black electromagnetic shielding fabric provided in Example 1 of the present invention.

[0054] Table 1 The main performance ...

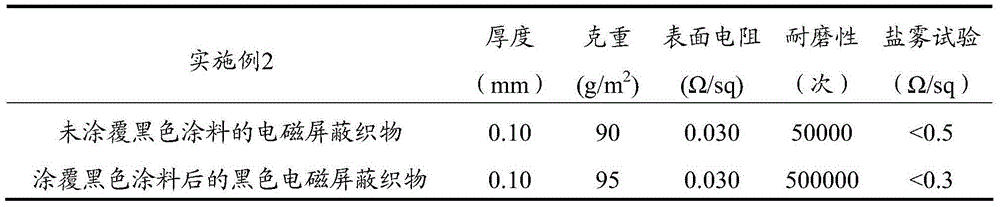

Embodiment 2

[0058] Be 1:1 according to mass ratio, epoxy resin and PI resin are mixed, obtain the mixture of epoxy resin and PI resin; Get 20g described mixture, mix it and 0.5g curing agent and 6g color paste at room temperature, and Stir thoroughly for 10 minutes to prepare a black paint.

[0059] The electromagnetic shielding fabric is the NF36B product produced by Sanyuan Electronic Technology Co., Ltd.; the black paint is evenly coated on the electromagnetic shielding fabric, and the coating amount is 12g / cm 2 , and then dried at 130° C. to obtain a black electromagnetic shielding fabric sample compounded with a dense and uniform black coating.

[0060] According to the method described above, the abrasion resistance and corrosion resistance tests were carried out on the samples respectively, and the results are shown in Table 2. Table 2 shows the main performance results of the black electromagnetic shielding fabric provided in Example 2 of the present invention.

[0061] Table 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com