Plastic centrifugal pump

A centrifugal pump and plastic technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of short service life, reduce product yield, increase production costs, etc., achieve good economic benefits and energy saving, reduce Convective shock, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

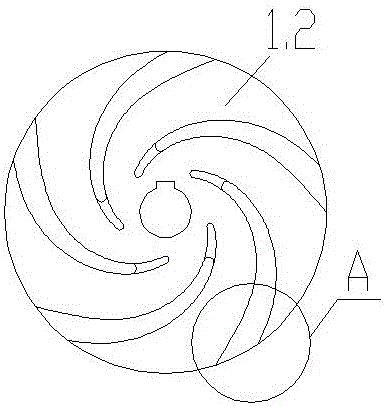

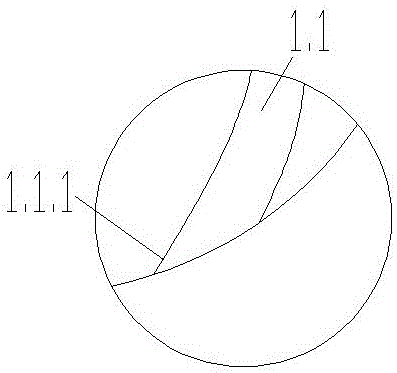

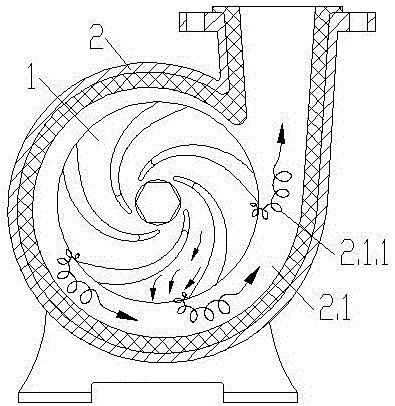

[0032] Embodiment 1: as Figure 4~7 , a plastic centrifugal pump, including a pump casing 2, a main shaft 5, a shaft seal 6 on the main shaft 5, a bearing seat 4, and an impeller 1 installed at the end of the main shaft 5 and located in the volute cavity of the pump casing 5, and the impeller 1 includes an impeller spoke The impeller blade 1.1 on the plate 1.2 and the impeller width plate 1.2, the inwardly curved side cut of the tail of the impeller blade 1.1 is provided to make the flow direction angle of the fluid thrown out of the impeller flow channel liquid outlet 1.2 larger, so that the fluid flows from the impeller flow channel liquid outlet 1.2 Inclined diversion angle 1.1.1 for forward flow towards the outlet of the pump volute flow channel. Inclined diversion angle 1.1.1 The angle E of the end point B along the tangent of the arc surface and the axis formed by the end point B and the center O of the impeller 1 is 10~40 degrees. The straight-line distance D between t...

Embodiment 2

[0040] Embodiment 2: with reference to embodiment 1, as Figure 4~12As shown, the head, flow rate, diameter and other performance parameters of the centrifugal pump can be selected arbitrarily according to the needs. Then choose ultra-high molecular weight polyethylene with a molecular weight of 5 million as raw material, and use the method of molding to make a steel-lined plastic pump casing 2, pump cover 3, and impeller 1, and then cut and process the diversion angle at the tail of the blade 1.1 of the impeller 1. 1.1.1, each part is trimmed and deburred, and then assembled with the processed main shaft, shaft seal, bearing seat and other pump components in a conventional way, and then assembled with the motor and base to form a plastic centrifugal pump. After debugging, painting , packaging and other processes, you can get an improved plastic centrifugal pump whose efficiency is about 2~4% higher than that of conventional plastic centrifugal pumps.

[0041] The impeller se...

Embodiment 3

[0043] Embodiment 3: Referring to Embodiment 2, ceramics and silicon carbide can be selected as the flow-through material of the impeller, the pump casing, and the pump cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com