Aluminum-plastic film and preparation method thereof

An aluminum-plastic film and plastic layer technology, applied in chemical instruments and methods, other household appliances, structural parts, etc., to achieve the effects of improved warpage, large shrinkage, and increased shrinkage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing the aforementioned aluminum-plastic film. The first plastic layer is prepared by co-extrusion cast film formation, and in the process of co-extrusion cast film formation, different extrusion dies are used to extrude the corresponding materials of the corona layer, heat-resistant layer and heat-sealing layer At the same time, different extrusion dies are used to respectively extrude the materials of the cladding layer and the core layer; an aluminum foil layer is provided, and the first plastic layer is adhered to the first surface of the aluminum foil layer; a second plastic layer is provided, and the second plastic layer is provided. Two plastic layers are adhered to the second surface of the aluminum foil layer.

[0060]The present invention prepares the first plastic layer by means of co-extrusion casting film, adopts different extrusion dies to respectively extrude the corresponding materials of the corona l...

Embodiment 1

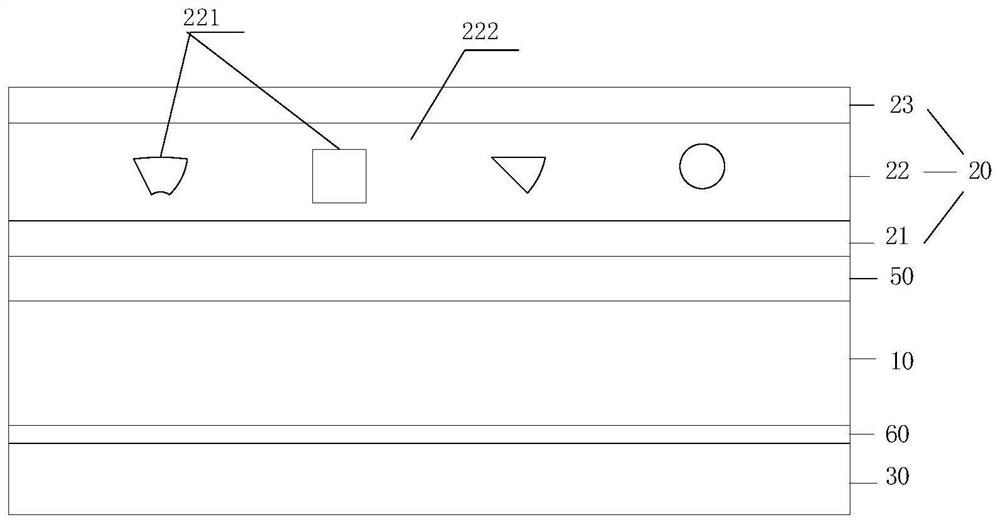

[0073] In this embodiment, a kind of aluminum-plastic film is made, such as Figure 4 As shown, it includes a first plastic layer, a first adhesive layer, an aluminum foil layer, a second adhesive layer, and a second plastic layer from top to bottom. The specific preparation method is as follows:

[0074] Step 1: Use different extrusion dies to extrude the corresponding materials of the corona layer, heat-resistant layer and heat-sealing layer, and in the process of extruding the heat-resistant layer, use different extrusion dies to respectively extrude the package Materials for cladding and core and complete cladding, where:

[0075] In the heat-sealing layer, the content of homopolypropylene material (Borealis BC300BF) is 80 parts, the content of polyolefin elastomer material (ExxonMobil 9061) is 20 parts, and additional processing aid PPA (0.6 parts) and antioxidant are added (0.2 part of antioxidant 619), slippery agent (0.1 part of oleic acid amide), antistatic agent (0...

Embodiment 2

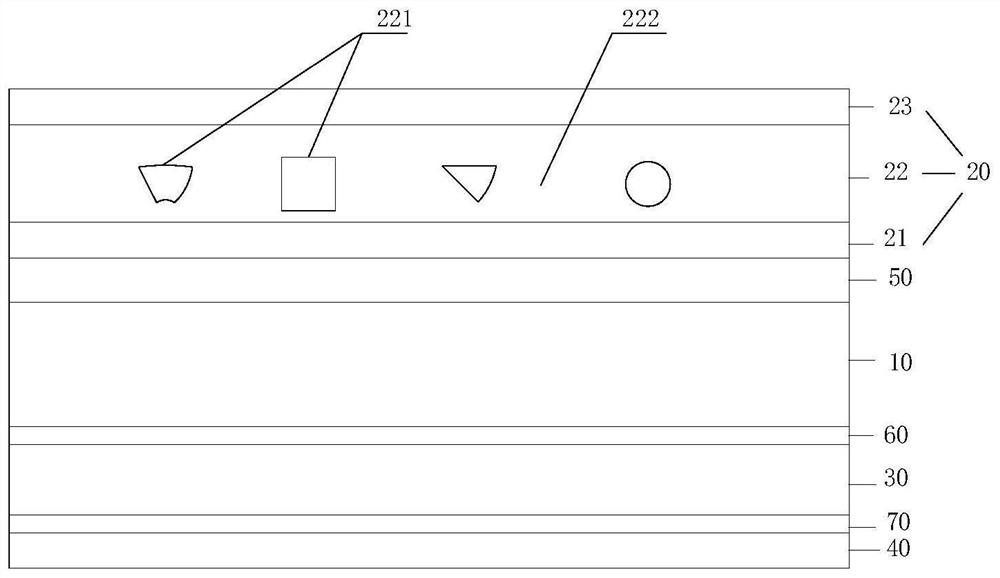

[0083] In this embodiment, a kind of aluminum-plastic film is made, such as Figure 5 As shown, it includes a first plastic layer, a first adhesive layer, an aluminum foil layer, a second adhesive layer, a second plastic layer, a third adhesive layer, and a third plastic layer from top to bottom. The specific preparation method is as follows:

[0084] Step 1: Use different extrusion dies to extrude the corresponding materials of the corona layer, heat-resistant layer and heat-sealing layer, and in the process of extruding the heat-resistant layer, use different extrusion dies to respectively extrude the package The materials of cladding layer and core layer and complete cladding, also include processing aid (PPA 0.6wt%), antioxidant (antioxidant 6190.15wt%), cool Slip agent (erucamide 0.15wt%). in:

[0085] The content of homopolypropylene material (Hanwha Total Petrochemical RF402) in the heat-sealing layer is 100wt%, the thickness of the heat-sealing layer is 15 μm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com