Electric contact point and contact element

A technology of electrical contacts and contacts, which is applied in the direction of contacts, contact materials, circuits, etc., can solve the problems of increased arc generation and increased consumption of electrical contact materials, and achieves reduced consumption and low-cost opening and closing Equipment, the effect of shortening the duration of tremors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A silver alloy material having a composition of 91Ag-5.8Sn-3In-0.2Ni in mass % was produced by a dissolution method, and rolling and annealing were repeated to obtain a desired sheet. In addition, in the present invention, as long as it is a silver alloy such as an Ag-Ni alloy or an Ag-W alloy used as an electrical contact material, or an internal oxidation treatment is performed in a post-process to form a silver oxide electrical contact material material, any silver alloy material can be used.

[0044] Form a kind of composite material, and this composite material is to be compounded as the pure silver plate that the thickness of pure silver layer 2 is 3~30% of the total thickness of electric contact on one side of this plate and forms. In addition, in the present invention, when the pure silver layer 2 is less than 3% of the thickness of the electrical contact layer, the bonding strength with the functional layer is not ideal; , the bonding strength was not found to...

Embodiment 2

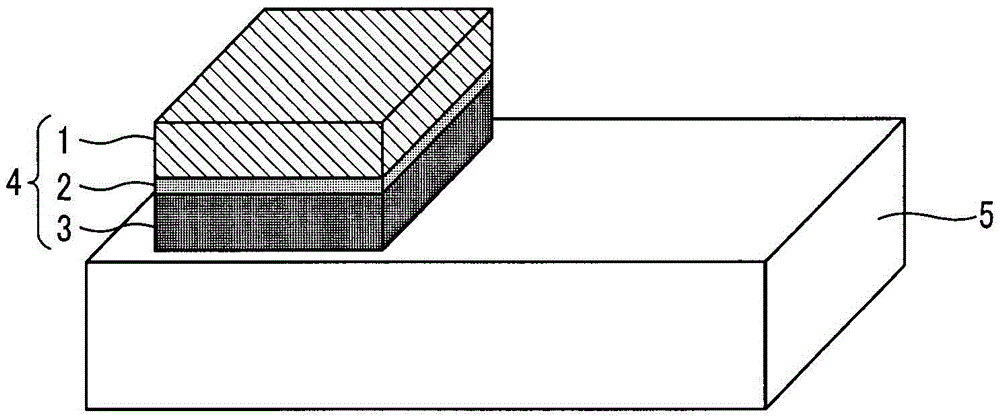

[0048] In the same way as in Example 1, the contacts (figure 1 ) (Types of electrical contacts No.6~10). Furthermore, the functional layer has a Vickers hardness of 94 and the base material of the contact has a Vickers hardness of 140.

Embodiment 3

[0050] Using the composite material obtained by the same method as in Example 1, a disc-shaped composite material of 10 mmφ was obtained by press punching.

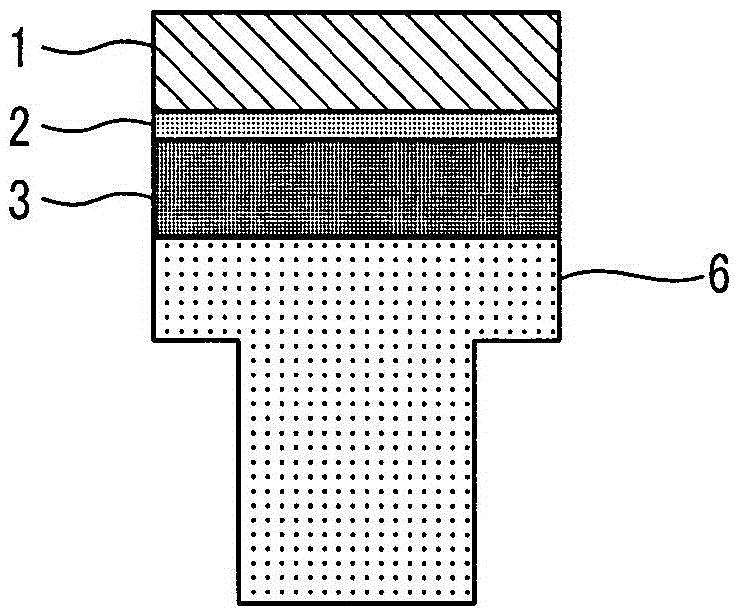

[0051] The 10mmφ composite material obtained in this way is subjected to barrel polishing and internal oxidation treatment, and the functional layer 3 is made of oxygen-free Cu (Vickers hardness 74) with a thickness of 1 to 50% of the total thickness of the electrical contact. After the plate is bonded to the composite material, it is brazed with a rivet-shaped base material 6 composed of oxygen-free Cu (Vickers hardness 110) to form an electrical contact ( figure 2 ).

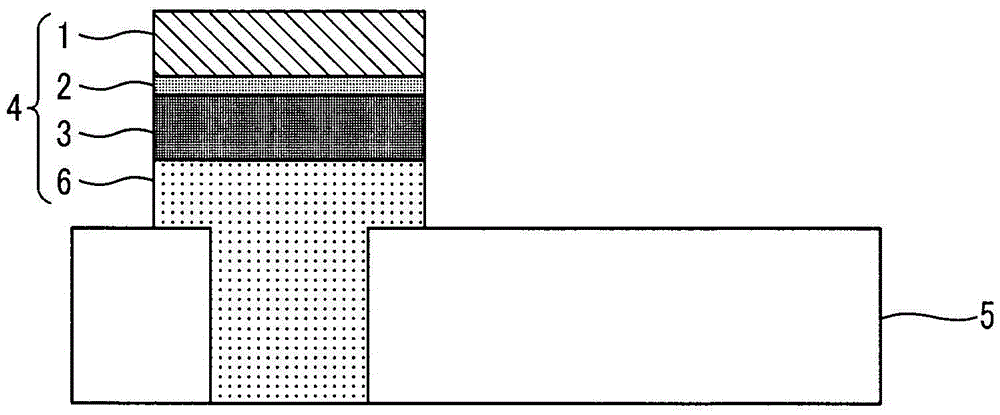

[0052] Such an electrical contact 4 is riveted and joined by a rivet-shaped base material 6 to a contact base material 5 made of oxygen-free Cu (Vickers hardness 110) to form a contact ( image 3 ) (Types of electrical contacts No.11~15).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com