Electronic part mounting apparatus and method of mounting electronic part

一种电子元器件、安装装置的技术,应用在电气元件、电气元件、电固体器件等方向,能够解决接合条件维持管理困难、裕度小等问题,达到接合条件的维持管理容易、确保合格品的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

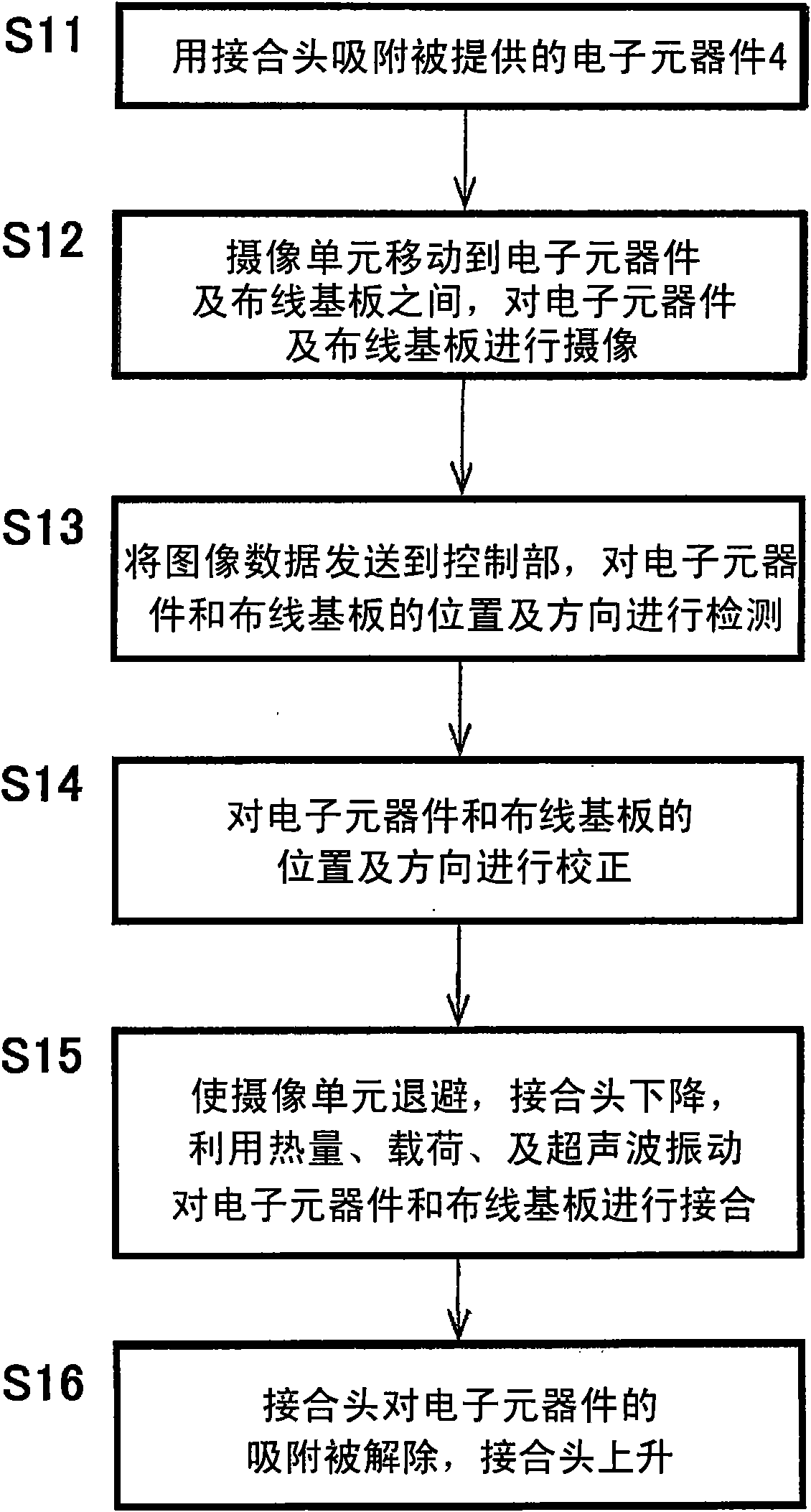

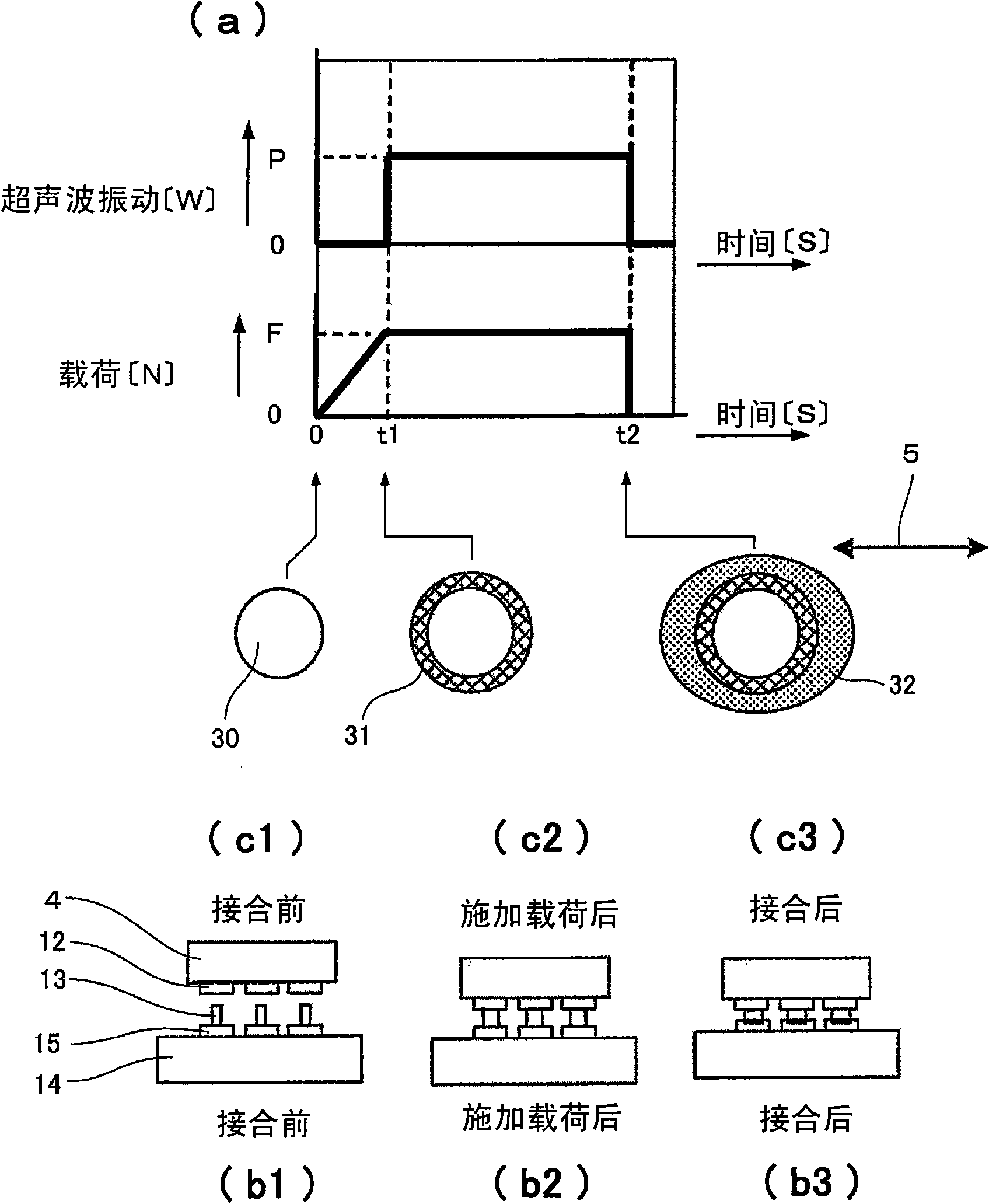

[0048] Figure 1 to Figure 10 Embodiments of the present invention are shown.

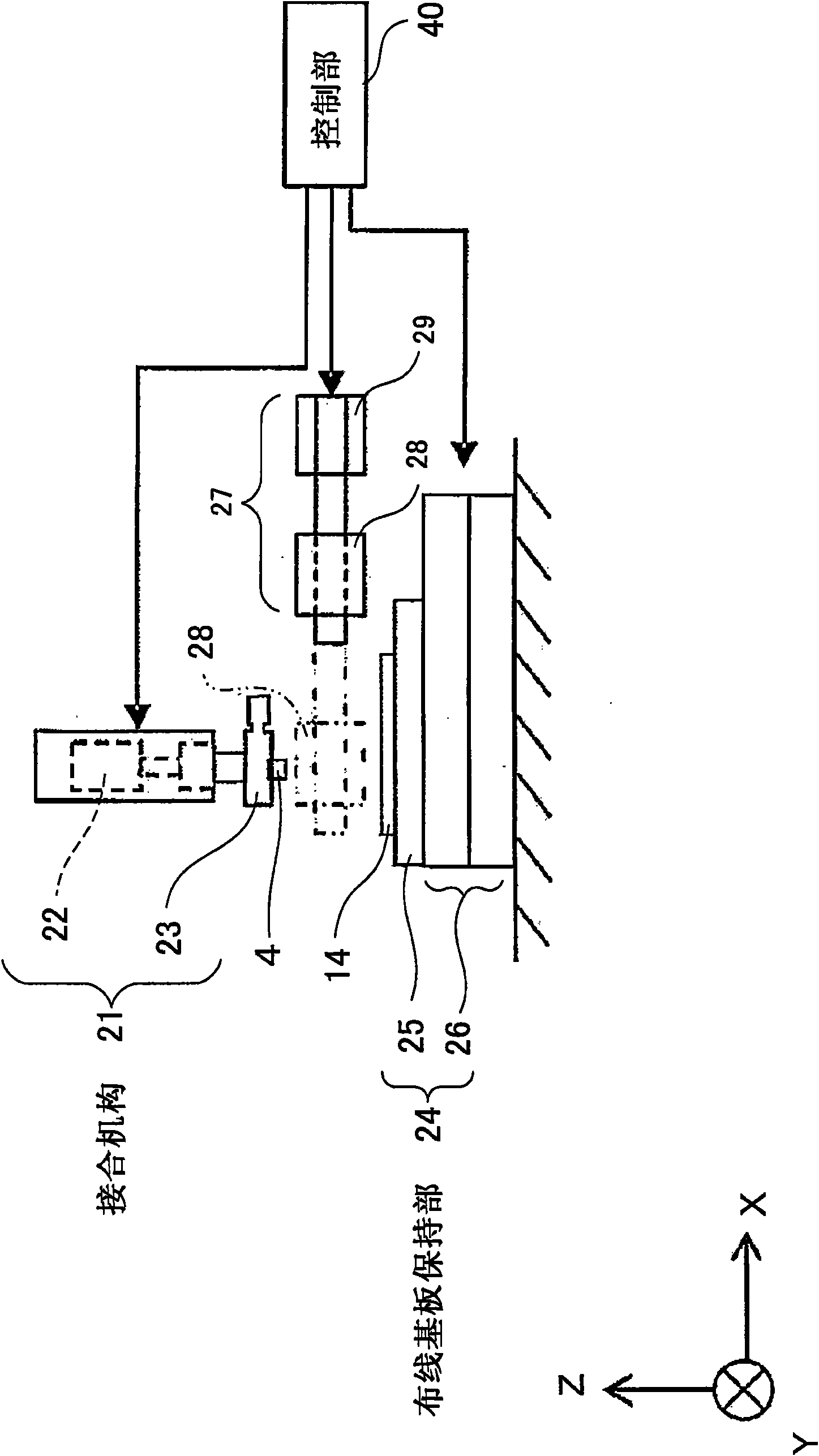

[0049] figure 1 It is a schematic configuration diagram of the ultrasonic bonding device of the present invention.

[0050] This ultrasonic bonding apparatus includes a wiring board holding portion 24 holding a wiring board 14 , and a bonding mechanism 21 for bonding an electronic component 4 to the wiring board 14 is provided on the +Z direction side of the wiring board holding portion 24 . An imaging mechanism 27 for imaging the electronic component 4 and the wiring substrate 14 is provided between the wiring substrate holding portion 24 and the bonding mechanism 21 . Moreover, the supply mechanism (not shown) which supplies the electronic component 4 to the bonding mechanism 21 is provided. In this ultrasonic bonding apparatus, the control unit 40 controls these mechanisms to bond the wiring board 14 and the electronic component 4 .

[0051] The wiring board holding unit 24 includes a table...

Embodiment approach 2

[0097] In addition, in addition to any one of the tools 3 shown in the above-mentioned embodiment 1, it is also possible to Figure 11 or Figure 12The ultrasonic horn 2 is constituted in such a way that the magnitude of the ultrasonic vibration acting on the electronic component 4 is changed.

[0098] Figure 11 It is a partial perspective view showing the ultrasonic horn 2 and the tool 3 according to the second embodiment.

[0099] The hole portion 50 is formed in the ultrasonic horn 2 . In this example, holes 50 are formed on both sides of the tool 3 of the ultrasonic horn 2 in a direction parallel to the ultrasonic vibration direction 5 given by the ultrasonic vibrator 1 . The shape and size of the hole portion 50 are set so that there is no vibration difference between the center portion 3 a and the end portion 3 b of the tool 3 , or the vibration difference is small. In addition, a plurality of hole portions 50 may be formed.

[0100] Figure 12 Among them, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com