Sandwich anode structure of organic electroluminescent device and preparation method thereof

An electroluminescent device, anode structure technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

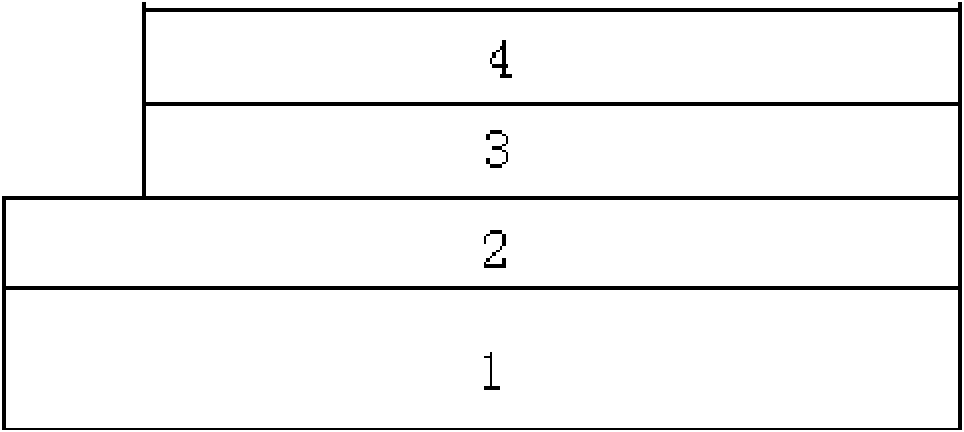

[0018] 1) First, a transparent conductive indium tin oxide film 2 with a thickness of 10 nm is deposited on a transparent glass substrate 1 by sputtering, chemical vapor deposition, spray pyrolysis, sol-gel method or pulsed laser deposition method;

[0019] 2) Secondly, on the transparent conductive oxide film 2, a Pt film 3 with a thickness of 10 nm is evaporated by vacuum evaporation;

[0020] 3) Finally, on the metal film 3, a layer of molybdenum oxide (MoO x ) film 4.

Embodiment 2

[0022] 1) First, a layer of transparent conductive ZnO film 2 with a thickness of 300nm is deposited on a transparent glass substrate 1 by sputtering, chemical vapor deposition, spray pyrolysis, sol-gel method or pulsed laser deposition method;

[0023] 2) Secondly, on the transparent conductive oxide film 2, a layer of Au film 3 with a thickness of 50 nm is evaporated by vacuum evaporation;

[0024] 3) Finally, a layer of tungsten oxide (WO) with a thickness of 100 nm is evaporated on the metal film 3 by vacuum evaporation. 2 ) film 4.

Embodiment 3

[0026] 1) First, a transparent conductive AZO (Al:ZnO) film 2 with a thickness of 800 nm is deposited on a transparent glass substrate 1 by sputtering, chemical vapor deposition, spray pyrolysis, sol-gel method or pulsed laser deposition method;

[0027] 2) Secondly, on the transparent conductive oxide film 2, a Ag film 3 with a thickness of 80nm is evaporated by vacuum evaporation;

[0028] 3) at last, on the metal thin film 3, adopt the method vapor deposition of vacuum evaporation to be the vanadium pentoxide (V 2 o 5 ) film 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com