Method for improving glass-to-glass full-fitting warping

A full-fit, hard-to-hard technology, used in optical components, optics, instruments, etc., can solve problems such as warping of hard-to-hard full-fit technology, and achieve good display effect, high flatness, and good optical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

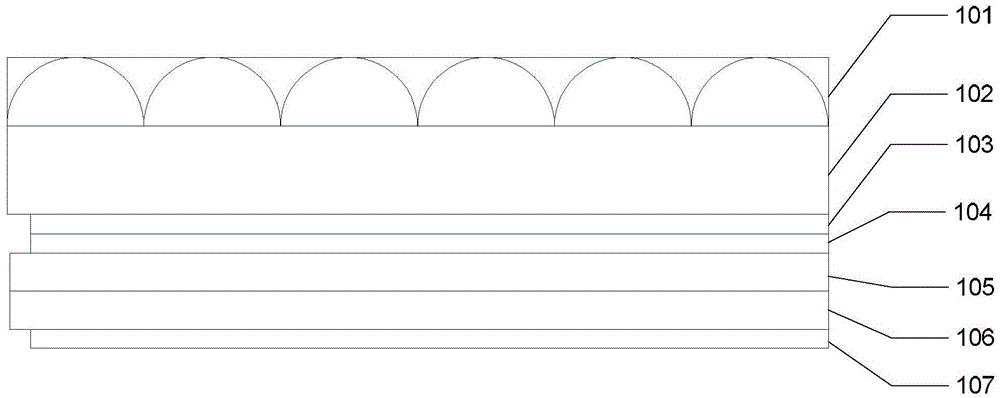

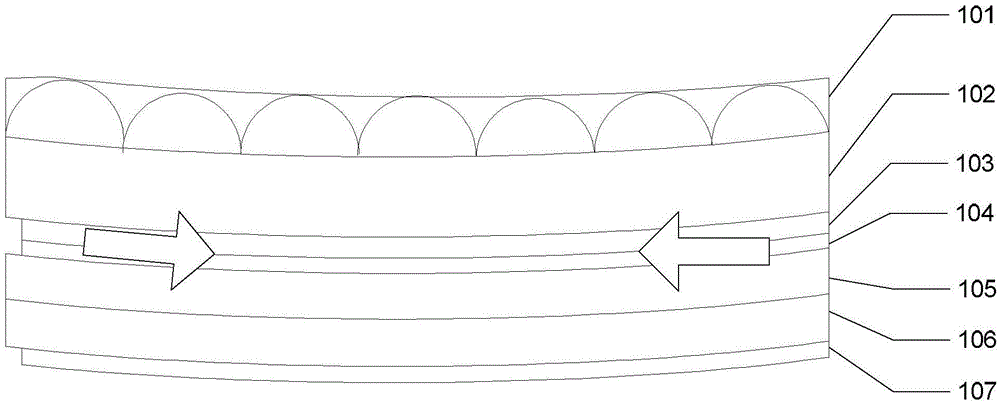

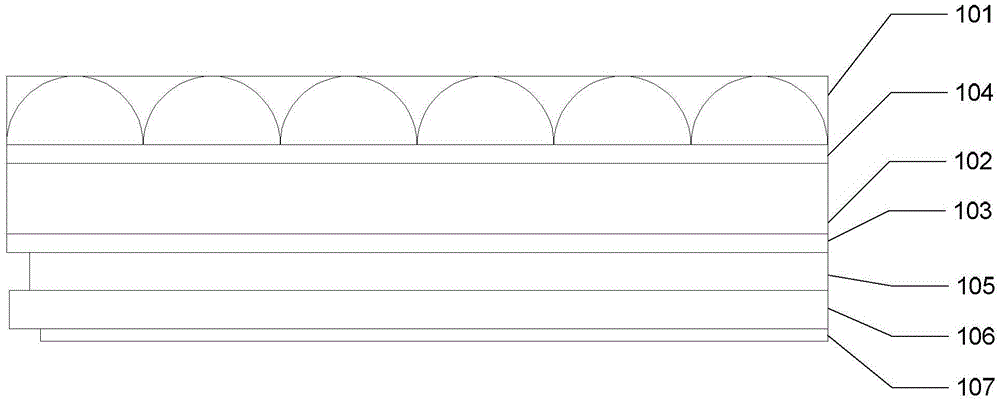

[0019] Specific implementation mode one: the following combination image 3 Describe this embodiment, the method for improving the warpage of hard-to-hard full lamination described in this embodiment, the method is: before the hard-to-hard lamination operation, the upper polarizer 104 is peeled off from the overall unit device of the display screen, and the optical glass 102 and C / F glass 105 are bonded with optical glue 103. After curing, the polarizer 104 is pasted on the outer surface of the optical glass 102, and finally the grating is pasted on the outer surface of the upper polarizer 104. 101. Complete the hard-to-hard full lamination process.

[0020] The full-fit naked-eye 3D display screen is composed of multiple functional structural layers: a touch screen integral unit device composed of grating 101 and optical glass 102; and an upper polarizer 104, C / F glass 105, TFT glass 106 and lower polarizer 107 display screen integral unit device. In order to achieve full l...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the grating 101 is pasted on the outer surface of the optical glass 102 first, and then the polarizer 104 is pasted back. The process effect is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com