Self-cleaning high-strength bar-shaped porcelain insulator

A porcelain insulator and high-strength technology, applied in the field of self-cleaning high-strength rod-shaped porcelain insulators and their preparation, can solve problems such as large losses, and achieve the effects of reducing cracks, improving overall strength and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

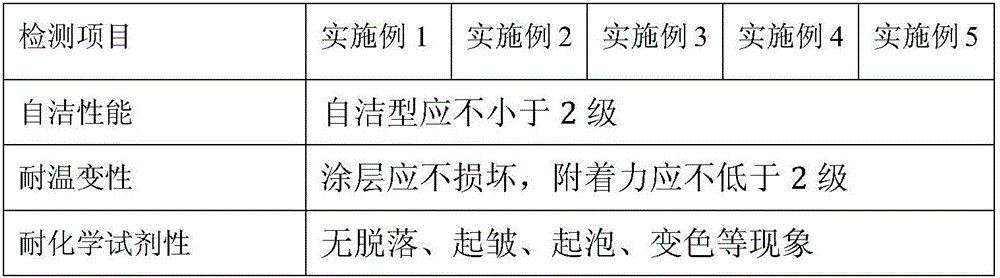

Examples

Embodiment 1

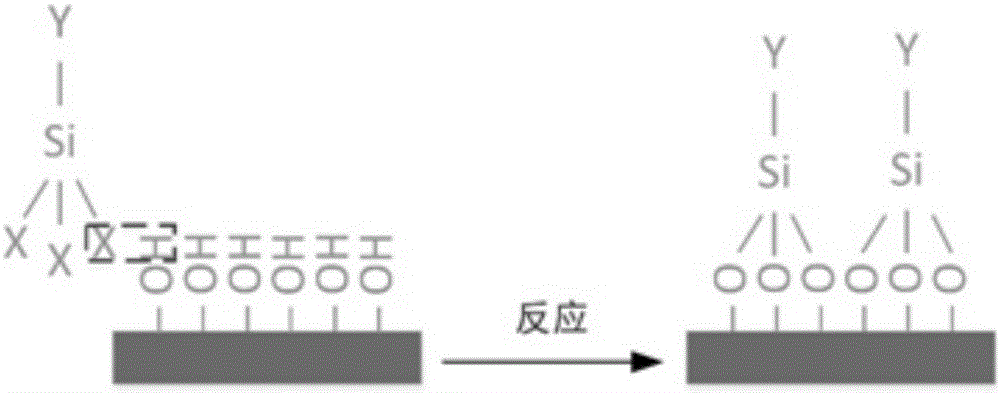

[0019] Embodiment 1: A self-cleaning high-strength rod-shaped porcelain insulator, including an insulator body, and one or several nano-molecular structure layers are arranged on the surface glaze layer of the body.

[0020] The preparation method of the above-mentioned self-cleaning type high-strength rod-shaped porcelain insulator, the method comprises the following steps:

[0021] 1) Dilute dodecyltrimethoxysilane 150 times in anhydrous ethanol solvent; obtain impregnation solution;

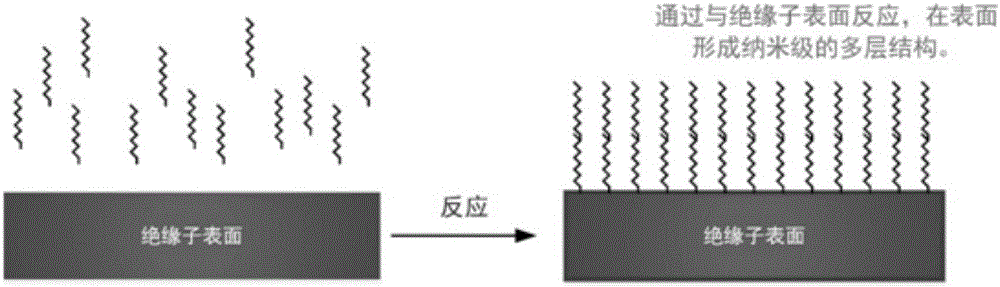

[0022] 2) Use ropes to cover both ends of the insulator and completely immerse in the immersion solution obtained in step 1) by lifting and moving. Naturally volatilize until the surface is dry and smooth, the volatilization time is 3-5min. After the organic solvent volatilizes, the long-chain single molecule grows one or several layers of nano-molecular structures on the glaze layer on the surface of the insulator, such as figure 2 shown; finally put the insulator vertically on the ground,...

Embodiment 2

[0025] Embodiment 2: It is basically the same as Embodiment 1, except that the long-chain alkylsilane is any one of vinyltriacetylsilane and butadienyltriethoxysilane.

[0026] The dilution factor in step 1) is 200 times.

Embodiment 3

[0027] Embodiment 3: basically the same as Embodiment 1, the difference is that the long-chain alkylsilane is any of dodecyltrimethoxysilane, vinyltriacetylsilane, butadienyltriethoxysilane A sort of.

[0028] The dilution factor in step 1) is 100 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com