Method for controlling polygonal abrasion of wheels of rail transit vehicle

The technology of a rail transit vehicle and a control method, which is applied in the field of control of polygon wear of rail transit vehicle wheels, can solve problems such as high economic cost and reduced service life of wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

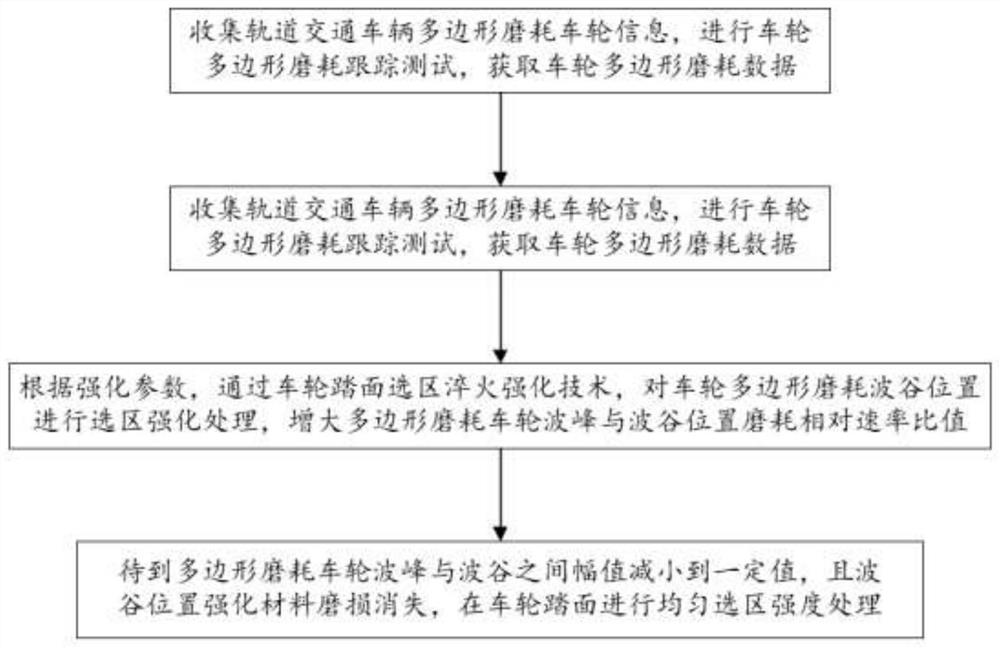

[0031] Such as figure 1 As shown, the present embodiment provides a method for controlling polygonal wear of a rail vehicle wheel, which includes the following steps:

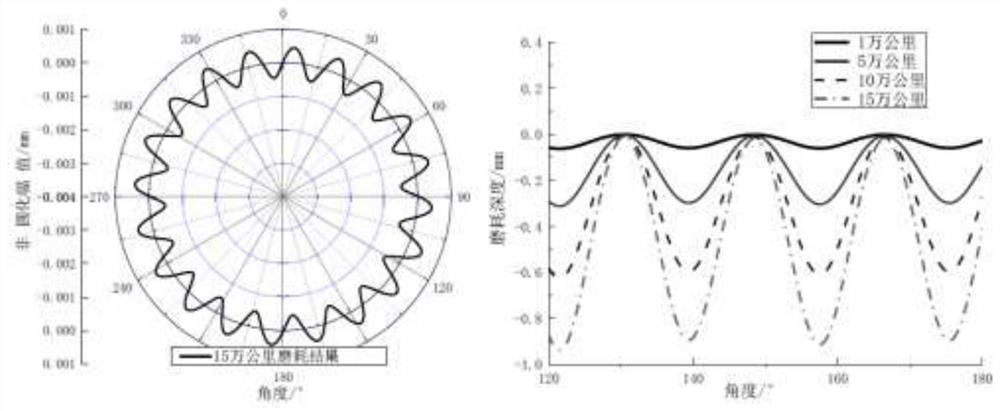

[0032] 1. Collect information on polygonal worn wheels of rail transit vehicles, such as operating conditions and on-site data, conduct wheel polygonal wear tracking tests, and obtain wheel polygonal wear data;

[0033] 2. Based on the wheel wear rate and the material wear characteristics of the wheel tread quenching and strengthening treatment, match the wheel selection strengthening parameters at the design trough position;

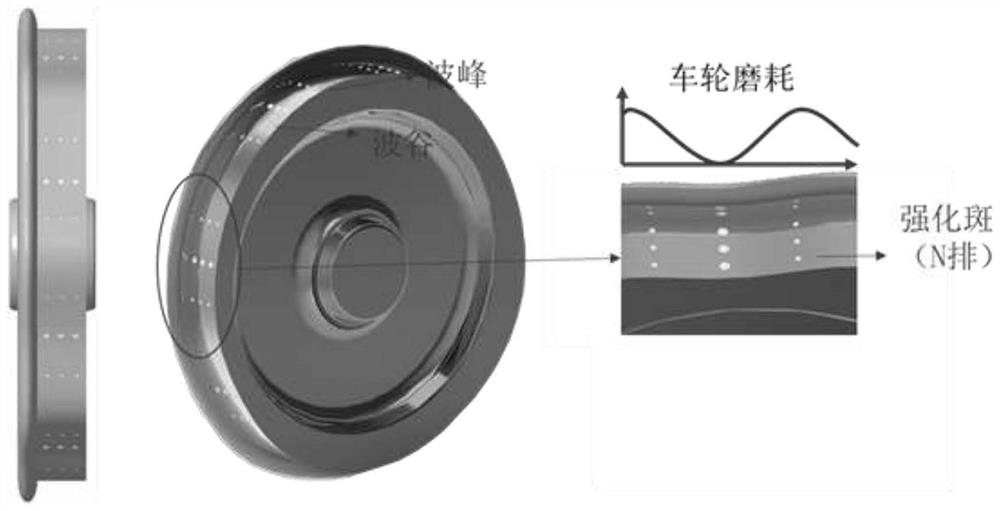

[0034] 3. According to the strengthening parameters, through the selective quenching and strengthening technology of the wheel tread, the polygonal wear trough position of the wheel is selected and strengthened, and the relative rate ratio of wear between the peak and the trough position of the polygonal worn wheel is increased; image 3 As shown, the wear rate of the wheel material at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com