Composite phenolic resin glue producing method

A technology of phenolic resin glue and production method, which is applied in the direction of adhesive type, adhesive, aldehyde/ketone condensation polymer adhesive, etc., can solve the problems of high shrinkage rate, high production cost, and high brittleness of wood-based panels, and achieve The effect of no change in strength and reduction in production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

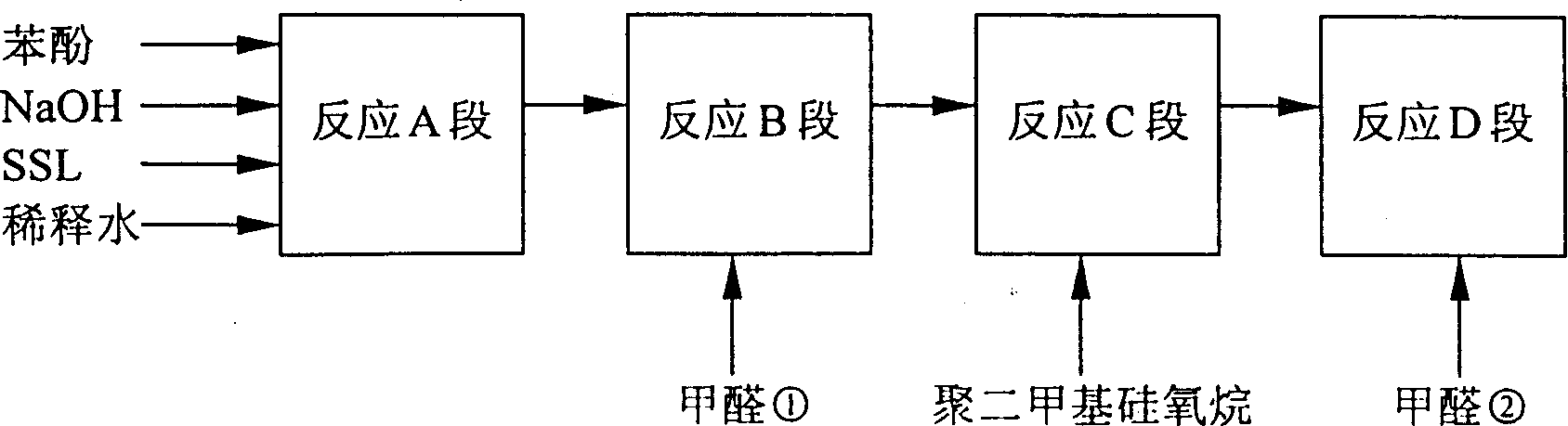

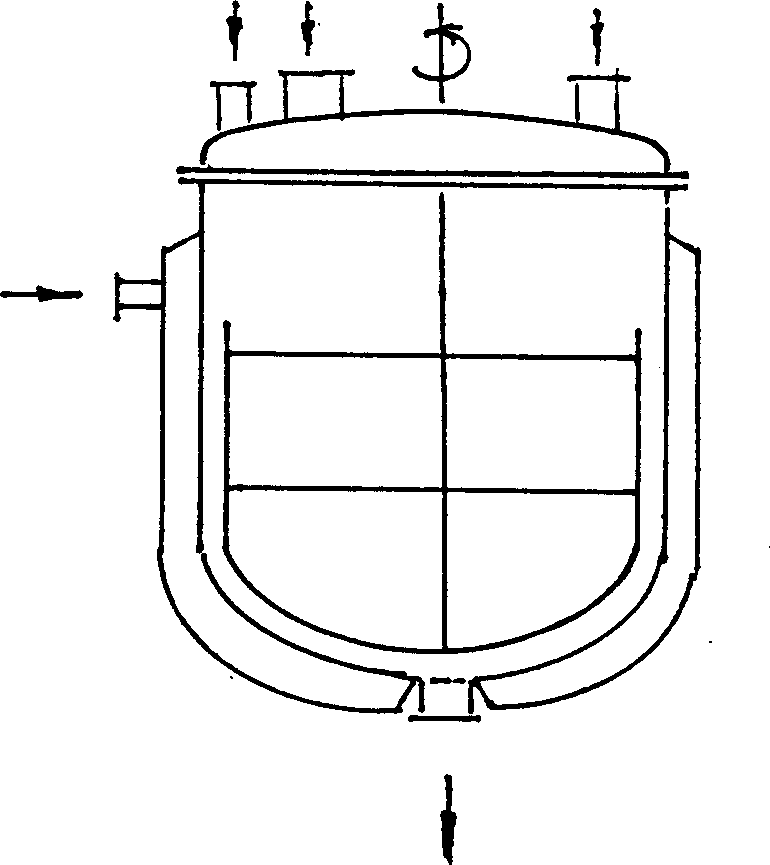

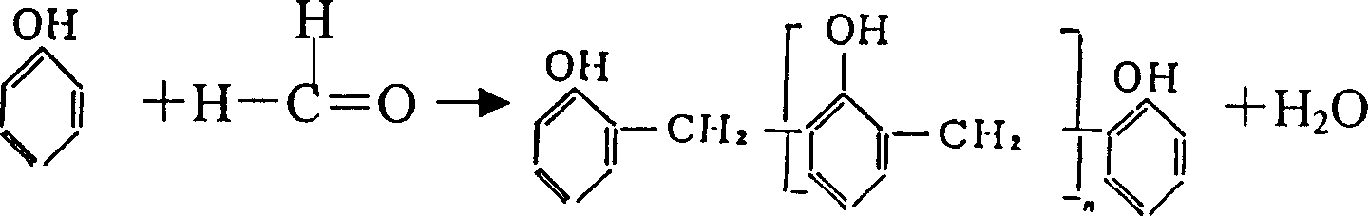

[0018] Embodiment 1, see Table 2, in reaction A section: NaOH, water, phenol are squeezed into reactor, NaOH weight, water weight are 1.16 times of phenol weight, start stirring, drop into sodium lignosulfonate, its weight is phenol 1.16 times the weight, fully stirred, and steam was introduced into the jacket to raise the temperature to 45°C and keep for 30 minutes; Reaction B section: add formaldehyde, the amount is 80% of the total amount of formaldehyde, that is, at this time, the mole of phenol and formaldehyde Ratio 1: 1.78, the temperature will rise when adding formaldehyde, the process water will be jacketed to keep the temperature at 45°C for 30 minutes; reaction section C: sodium lignosulfonate, phenol, and formaldehyde will react under the action of catalyst NaOH, clamp Put steam into the sleeve, and slowly raise the temperature to 94°C at a rate of 1°C per minute. When bumping or signs of bumping are found, add a little polydimethylsiloxane to control the reaction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com