Radiation protection material manufacturing method

A radiation protection and manufacturing method technology, applied in the direction of manufacturing tools, ceramic molding machines, shielding, etc., can solve the problems of high radiation protection cost of lead plates, surrounding environmental pollution, environmental pollution, etc., to achieve protection from scattered rays, Reduce secondary rays, good effect of anti-rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

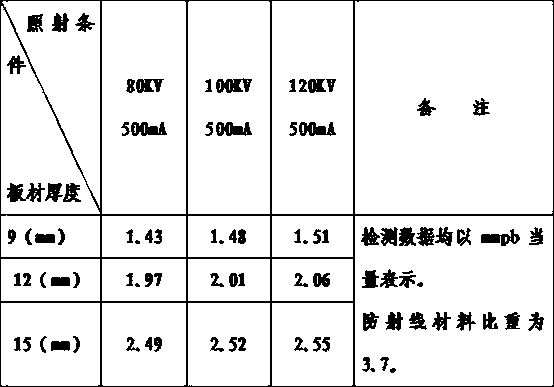

Image

Examples

Embodiment 1

[0010] 1. Mixing materials: 40% iron ore powder, 40% manganese ore powder, 10% copper ore powder, 10% unsaturated polyester resin, and the rest are additives.

[0011] 2. The above-mentioned materials are weighed, batched, stirred, and then sent to a vibration pressure molding machine. After being formed by vacuum vibration and pressure, they can be cured at room temperature or heated and cured at 50°C-180°C in a tunnel furnace or box-type cured. The furnace is heated and cured at 50°C-180°C. Then it is made into a standard radiation protection plate after thickness setting, polishing and trimming.

Embodiment 2

[0013] 1. Mixing materials: 45% iron ore powder, 35% manganese ore powder, 15% copper ore powder, 5% unsaturated polyester resin, and the rest are additives.

[0014] 2. The above-mentioned materials are weighed, batched, stirred, and then sent to a vibration pressure molding machine. After being formed by vacuum vibration and pressure, they can be cured at room temperature or heated and cured at 50°C-180°C in a tunnel furnace or box-type cured. The furnace is heated and cured at 50°C-180°C. Then it is made into a standard radiation protection plate after thickness setting, polishing and trimming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com