Precise and efficient colored titanium alloy preparation method adopting laser processing

A technology for laser processing and titanium alloys, applied in the field of titanium alloys and color titanium alloys by laser processing, can solve the problems of limited surface shape and area of processed objects, poor color stability of coatings and easy to fall off, and low efficiency of nano-lithography. The effect of high production efficiency, high selectivity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

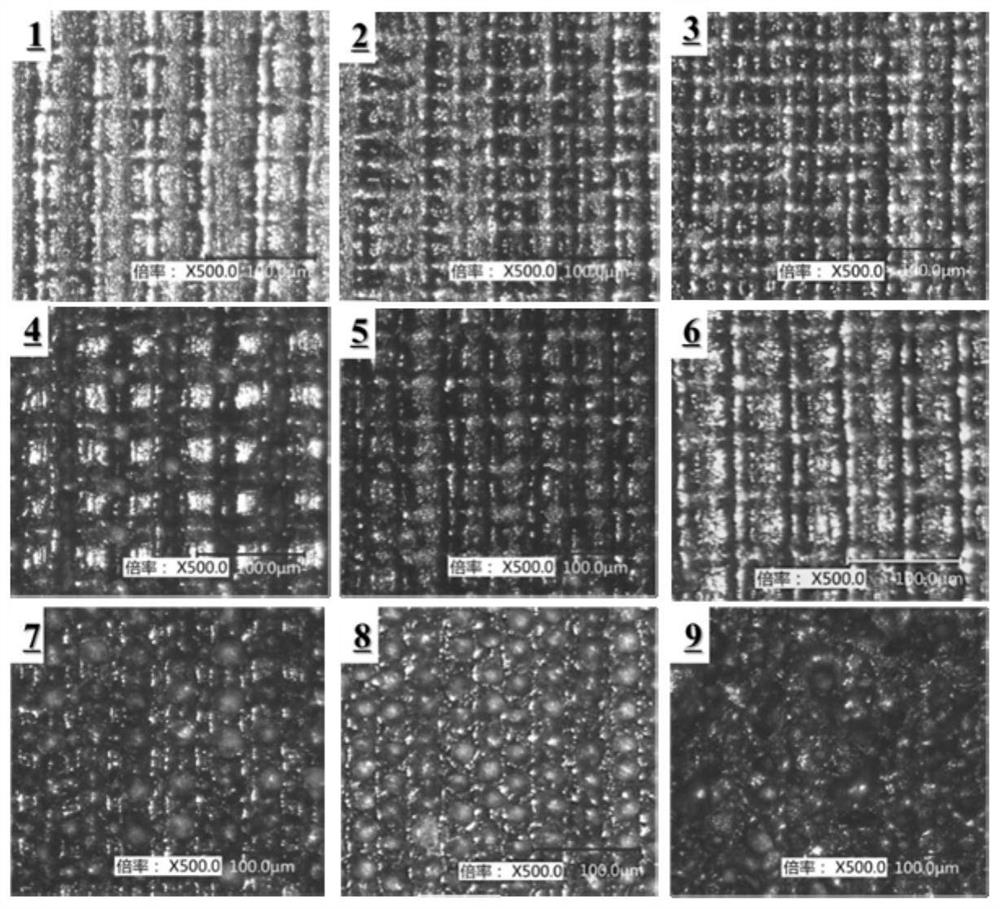

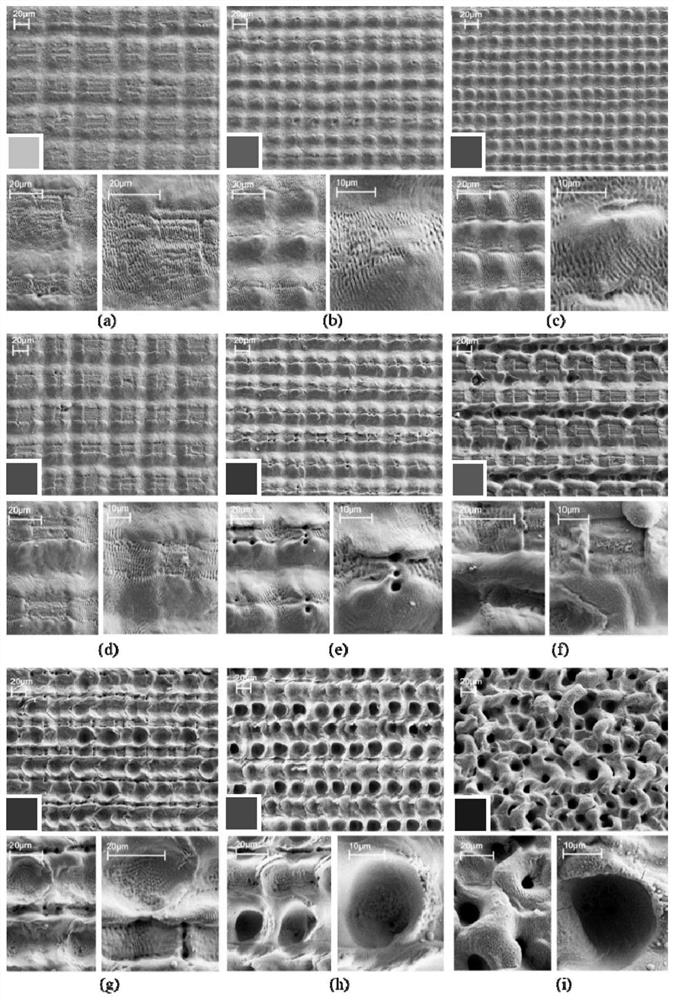

[0034] Such as Figure 1-3 As shown, the precision and high-efficiency color titanium alloy preparation method using laser processing includes the following steps:

[0035] Step 1. Put the TC4 titanium alloy with no obvious defects on the surface into 95% absolute ethanol, and only use 1000KHZ frequency for ultrasonic cleaning. After 10 minutes, take it out and dry it, and then place it on the processing table of the infrared picosecond laser;

[0036] Step 2. Use the ezCAD software that can control the work of the scanning galvanometer to select the laser parameters and processing parameters according to the surface coloring requirements, specifically laser pulse width: 7.5ps; laser wavelength: 1080nm; scanning speed: 50-200mm / s; average power : 6 ~ 8w; repetition frequency: 300 ~ 700kHz scanning spacing: 10 ~ 50μm;

[0037] Step 3. Do not open the laser shutter, only open the indicator light to scan the path, confirm the laser processing position, open the laser shutter aft...

Embodiment 2

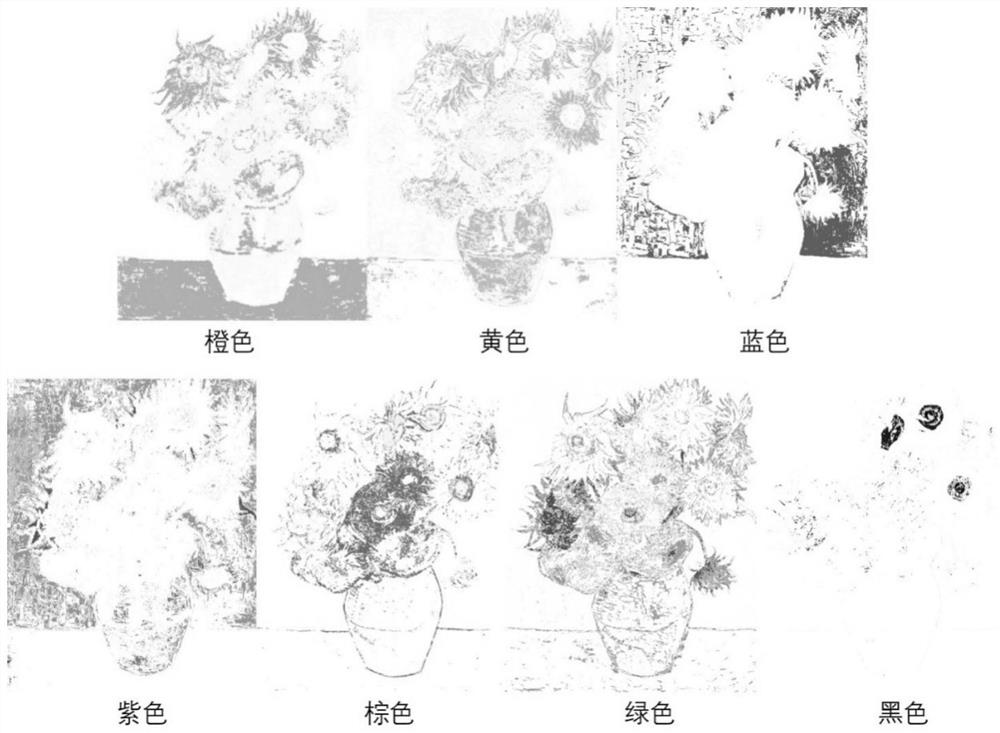

[0050] Such as figure 1 and 4 As shown, a: It is only necessary to use the circle to divide the processing area directly in ezCAD and perform horizontal / cross filling and processing according to the processing parameters of the corresponding color.

[0051] b: The image to be processed needs to be partitioned according to the color, and the areas with the same color number are extracted and saved in BMP format, and then several BMP images are imported into ezCAD software for graphic scanning and processing. Different images use the corresponding color parameter settings It can be processed sequentially. Taking b as an example, the processed image used in b is as follows Figure 4 As shown, the overlap problem caused by the size of the laser spot is considered during processing. It is best to process the large-area background color of the image first, and then process the key outline of the image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com