Method for fabricating compound heat preservation stone and dedicated die therefor

A technology of composite thermal insulation and production method, which is applied in the field of building materials, can solve the problems of unsatisfactory thermal insulation effect, slow progress and bulkiness of natural stone, and achieve the effect of beautiful texture, high production efficiency and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

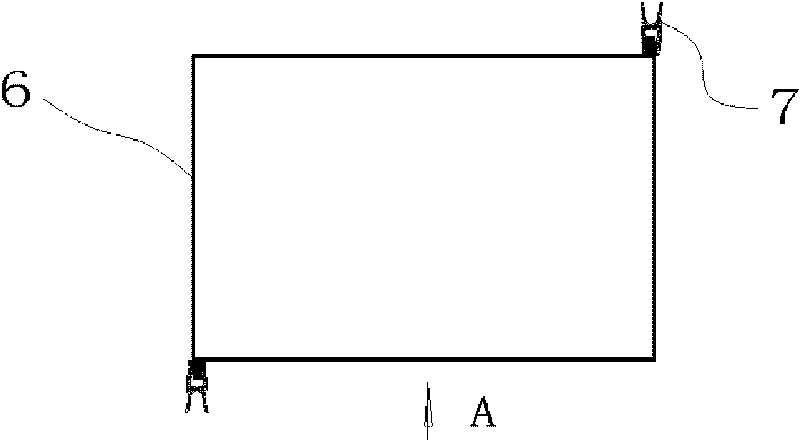

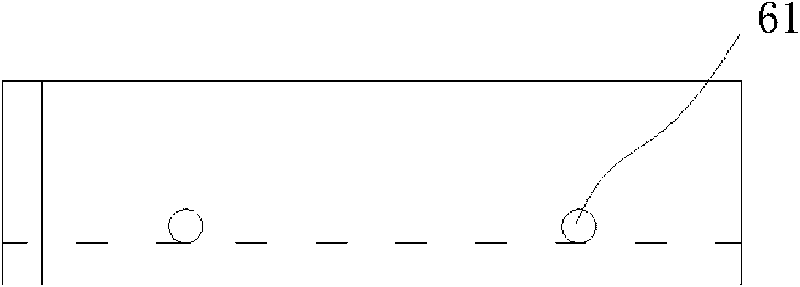

[0030] see figure 2 , image 3 , the present embodiment sets a special mold, and the special mold is made up of two rectangular half-frame molds 6, and two 3mm positioning holes 61 are respectively established on the opposite sides of a rectangle where the two half-frame molds 6 are combined, and each positioning A Φ3mm locating pin is equipped in the hole, and the positions of the locating hole 61 on the two half-frame molds 6 are on the same horizontal plane.

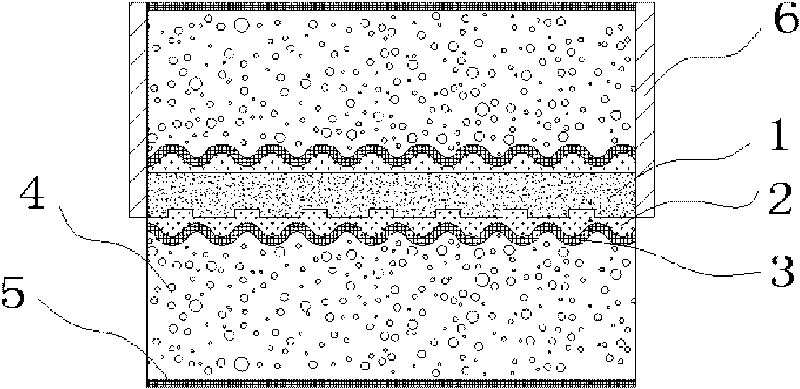

[0031] Such as Figure 4 As shown, take a natural stone 1, wherein one side is processed into a plurality of grooves 11 parallel to each other, the depth of the grooves 11 is less than one-eighth of the thickness of the natural stone 1, and the distance is two grooves 11 widths, and the other side is processed To form a plane, both surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com