High-power draught fan single pile sleeve cage assembly process

An assembly process and high-power technology, applied in infrastructure engineering, construction, etc., can solve the problems of cage dovetail buckle position accuracy not meeting requirements, affecting construction period, and inability to install, so as to reduce risks, reduce welding deformation, reduce The effect of small size deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

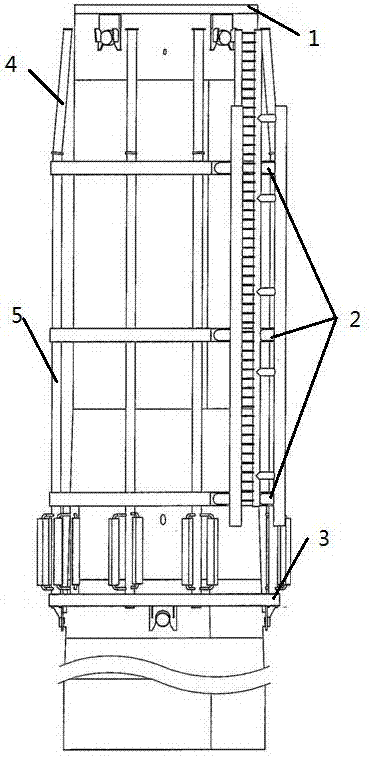

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0020] An assembly process for a high-power fan single-pile cage, the specific implementation steps are as follows:

[0021] a. Assembly, welding and opening of ring beams:

[0022] (1) Assembling and welding of the upper RHS420*300*20*30 ring beam Φ5960mm1: draw a cross center line on the workbench, determine the center position of the workbench, and draw on the workbench with a stylus according to the size requirements of the drawing Out of the position of the inner and outer plates of ring beam 1, the positions of four dovetail buttons are determined, and the four dovetail buttons are evenly distributed on the upper ring beam 1. The upper layer ring beam 1 is composed of six arc compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com