Start control process for COREX slag grinding production control system

A technology of production control and start-up control, which is applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as energy consumption, and achieve the effects of saving energy, improving service life, and rigorous processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment, further illustrate the present invention.

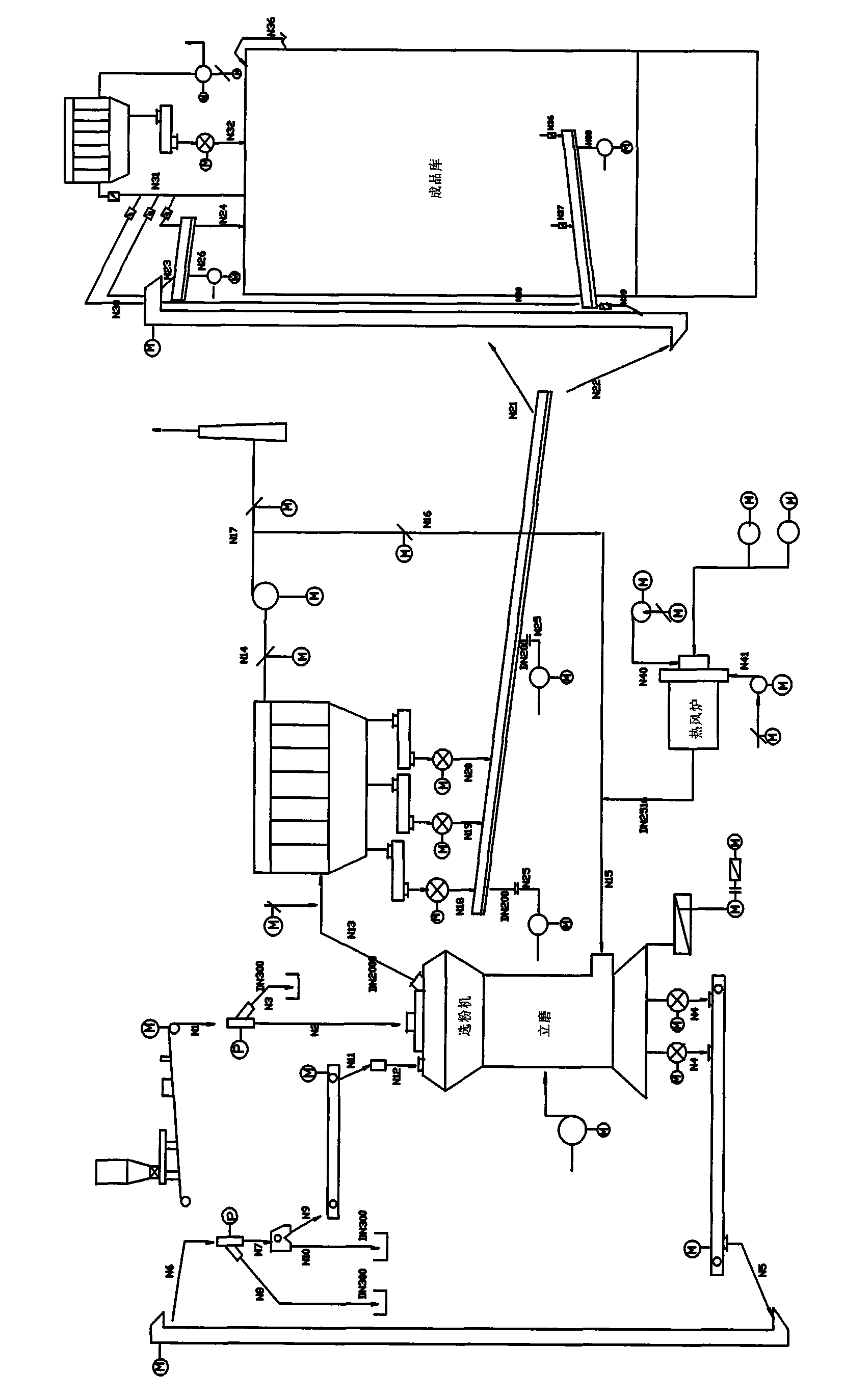

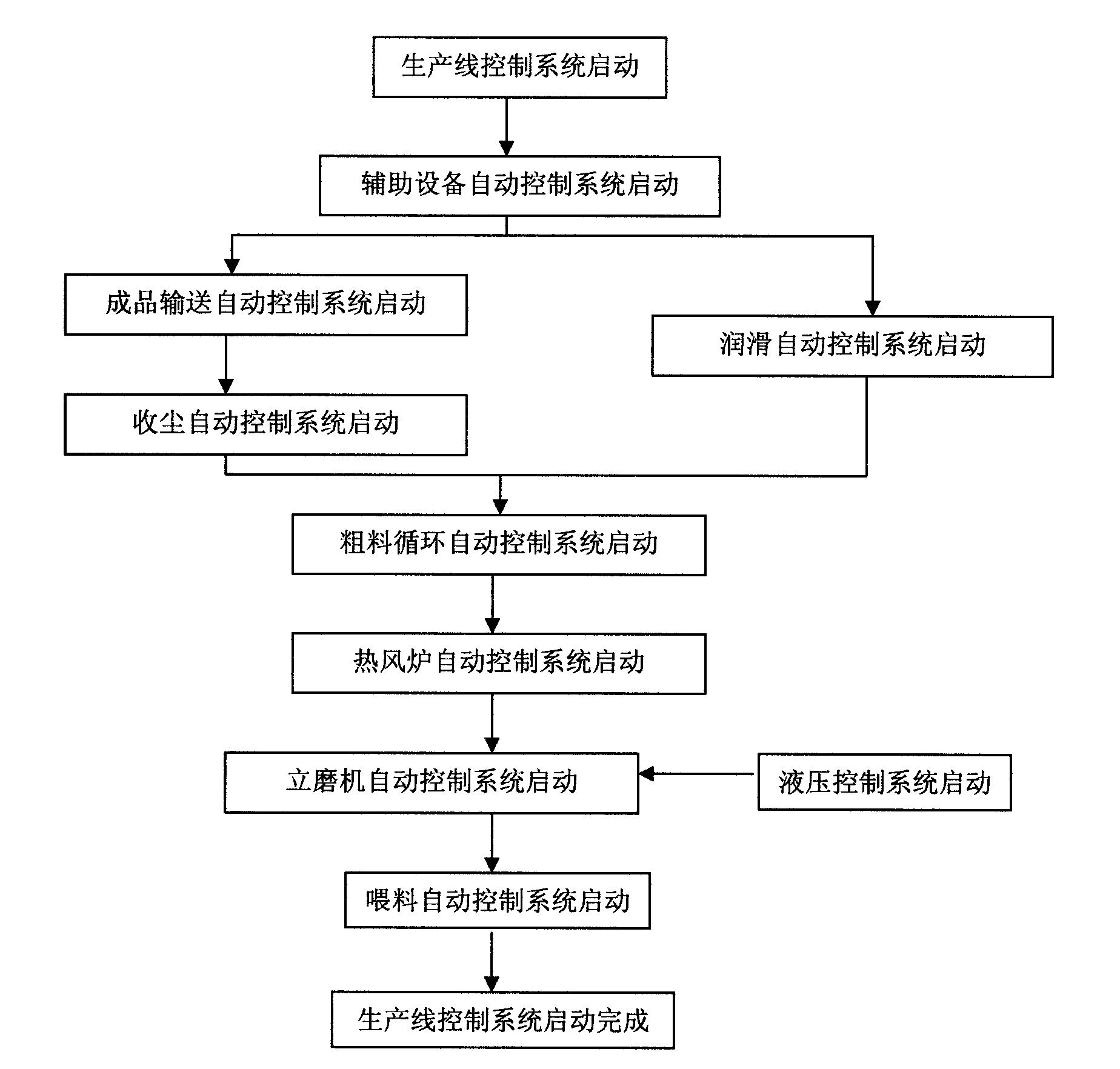

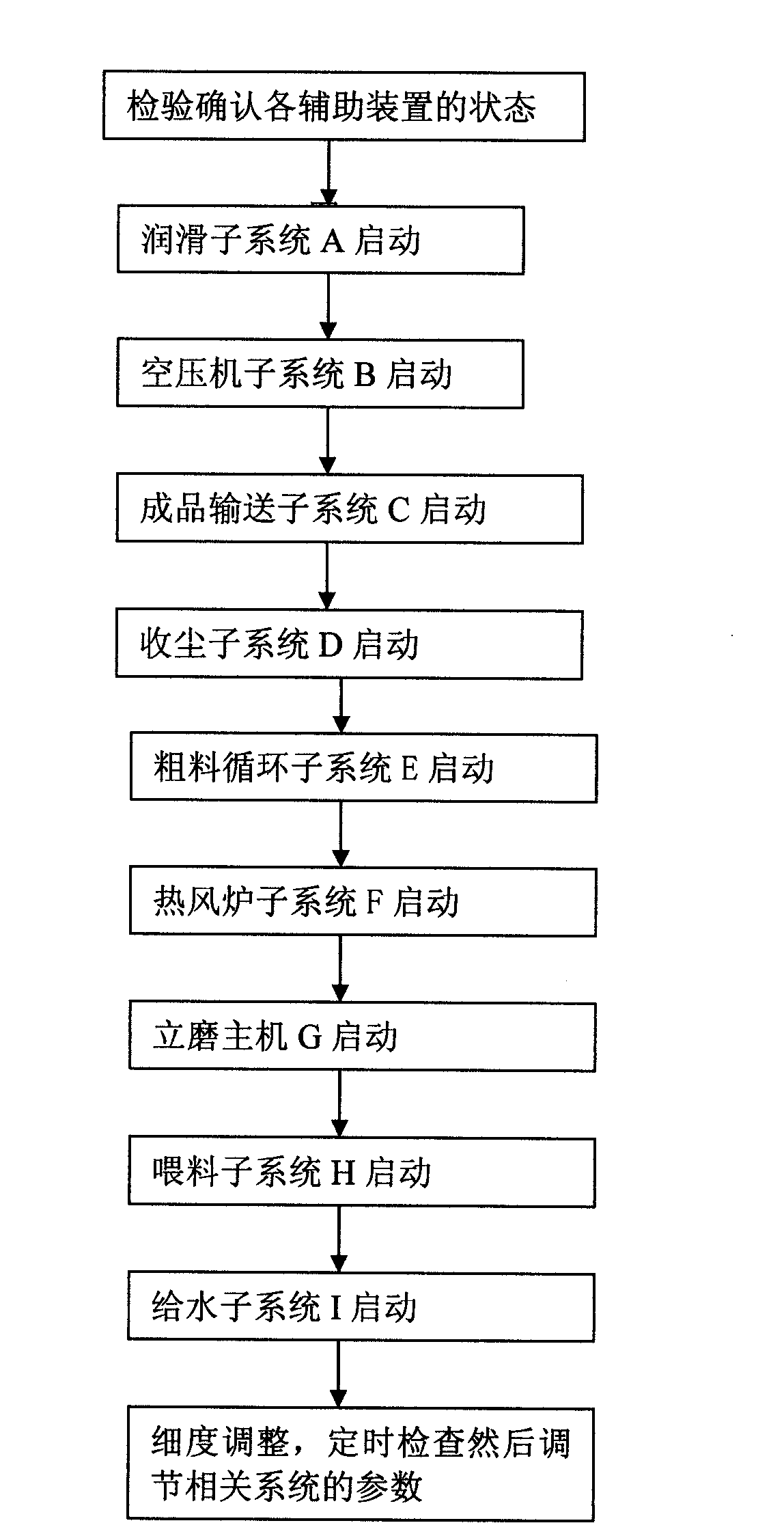

[0018] In order to improve the start-up control process of the existing COREX slag grinding production control system, the control system is divided into vertical mill main engine G and auxiliary lubrication subsystem A, air compressor subsystem B, finished product conveying subsystem C, dust collection Subsystem D, coarse material circulation subsystem E and hot blast furnace subsystem F, as well as feeding subsystem H and water supply subsystem I connected to the vertical mill, the lubrication subsystem includes the mill reducer lubrication unit, grinding roller spindle Lubrication unit, powder separator lubrication unit, powder separator reducer lubrication unit, also includes the previous single-row hydraulic unit and the previous sealed fan as auxiliary equipment.

[0019] The specific steps to start the control process are:

[0020] (1) Check and confirm the status of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com