Cylinder sleeve salt bath nitridation process

A salt-bath nitriding and cylinder liner technology, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of inaccurate process requirements, insufficient product precision, and insufficient process flow, etc. Rigorous process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

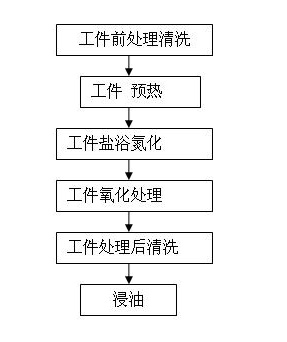

[0016] Such as figure 1 As shown, the salt bath nitriding process of the cylinder liner of the present invention includes the following steps: a. Pretreatment and cleaning of the workpiece. Before cleaning, the surface of the workpiece should be observed for rust and difficult-to-clean grease. If there is dirt such as grease, it should be Remove the rust by hand. The rust should be pickled or wiped with 1:1 hydrochloric acid. The pickled or wiped surface must be neutralized with sodium carbonate and then Na 2 CO 3 Rinse with clean water, hoist the pre-cleaned workpiece into a special appliance or a single-piece hanger, put it in the cleaning tank and move it up and down for 2-3 minutes, and observe whether there is oil or dirt, otherwise, the cleaning time should be further extended , Or to increase the concentration of the cleaning solution, either liquid or solid can be used for the cleaning solution, with a concentration of 1-5%, which can be adjusted according to the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com