Steel roof aluminum skirt piston machining process

A processing technology and piston technology, which is applied in the field of steel top aluminum skirt piston processing technology, can solve the problems of inaccurate process requirements, insufficient piston precision, poor product quality, etc., and achieve rigorous process flow, high product quality and high processing precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

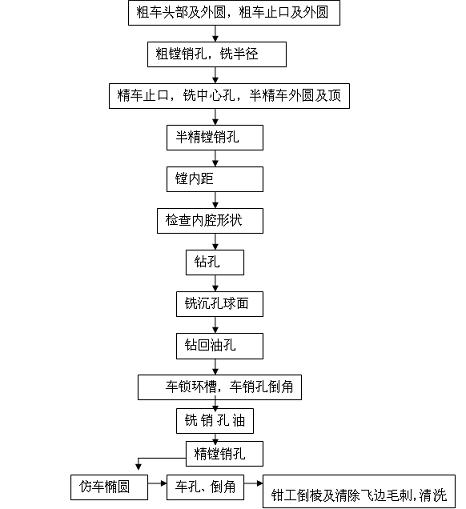

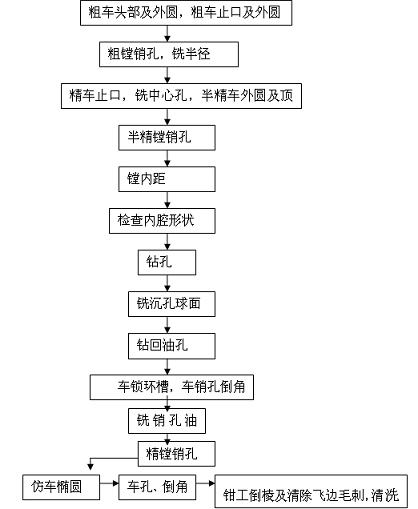

[0025] Such as figure 1 As shown, the steel top aluminum skirt piston processing technology of the present invention includes the following steps: step a, rough turning head and outer circle, rough turning seam and outer circle; step b, rough boring pin hole, milling 4-?25 radius ;Step c, finish turning the spigot, milling the center hole, semi-finishing the outer circle and the top surface; step d, semi-finishing the pin hole; step e, boring 60, 62 and 100 inner distances; step f, checking the shape of the inner cavity ; Step g, drilling 6-?8, 4-?13, ?6.5 and 2-?9 holes; Step h, milling 4-?27 counterbore spherical surface; Step j, drilling 2-?6 oil return hole; Step k , turning lock ring groove, turning pin hole chamfering; step L, milling pin hole oil groove; step m, fine boring pin hole; step n, imitating turning ellipse; step o, turning ?20 holes, 4-?13,2 - ?9, ?6.5 chamfering; step p, fitter chamfering and removing flash and burrs, cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com