Rolling friction or suspension friction impact excavating method and antiabrasion impact excavator for implementing the same

A technology of rolling friction and dynamic impact, applied in cutting machinery, driving devices, mining equipment, etc., can solve the problems of hydraulic cylinder damage, increase leakage, increase gap, etc., to prevent damage and widening of reaction force. The effect of righting width and increasing righting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

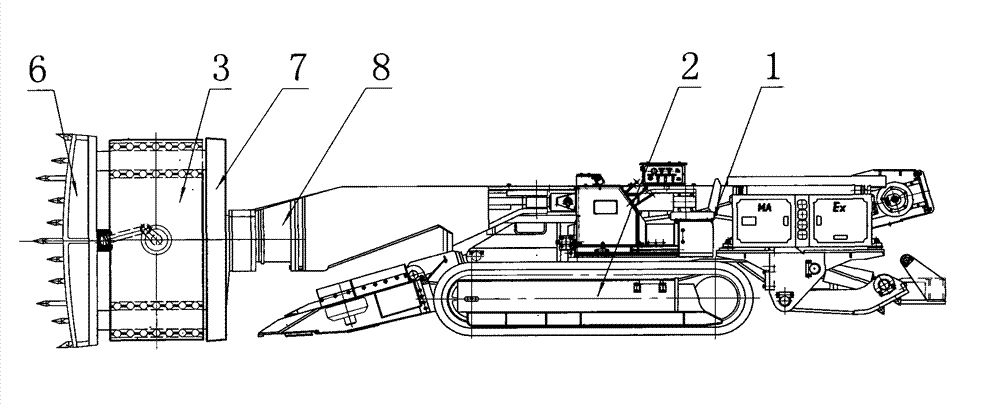

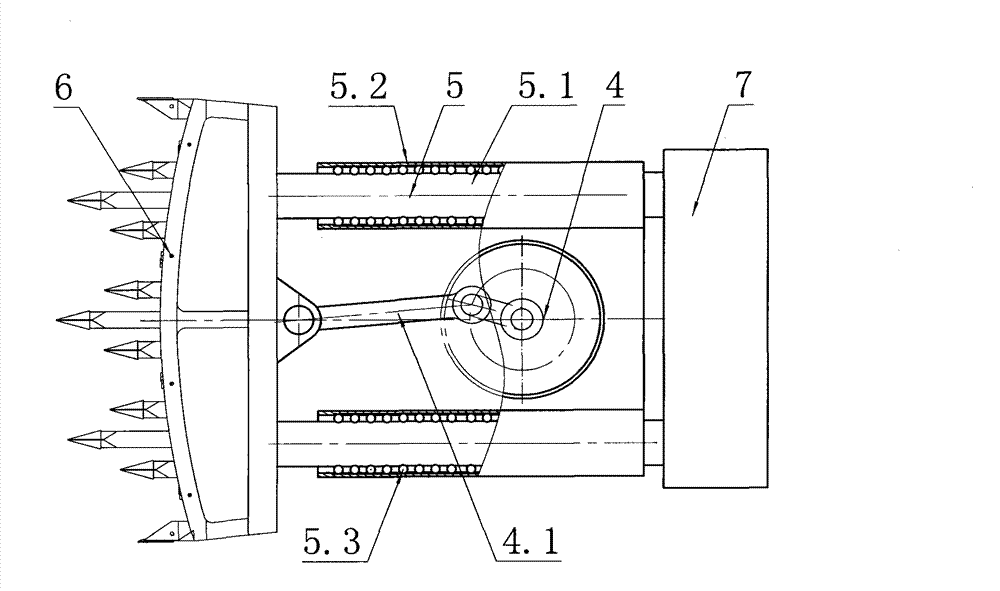

[0541] like Figure 1 to Figure 3 As shown, an anti-wear impact mining machine, the rolling friction impact mining machine includes a fuselage 1, a walking part 2, a reciprocating impact part 3, etc., the reciprocating impact part 3 includes a guide device 5, an impact drive device 4, etc., the guide device 5 Separated from the impact drive device 4, the guide device 5 includes an impact guide 5.1, a guide rolling body 5.3, a guide support 5.2, etc., the guide roll 5.3 is arranged between the guide support 5.2 and the impact guide 5.1, and the impact guide 5.1 The impact head 6 is set at one end and the other end is set to prevent the impact head 6 from being separated from the guide device 5, the impact drive device 4 and / or the fuselage 1 due to gravity imbalance. The counterweight 7, the impact head 6 is connected with the impact guide 5.1, The impact drive device 4 includes a power impact part 4.1, etc., the power impact part 4.1 drives the impact guide part 5.1 to recipro...

Embodiment 2

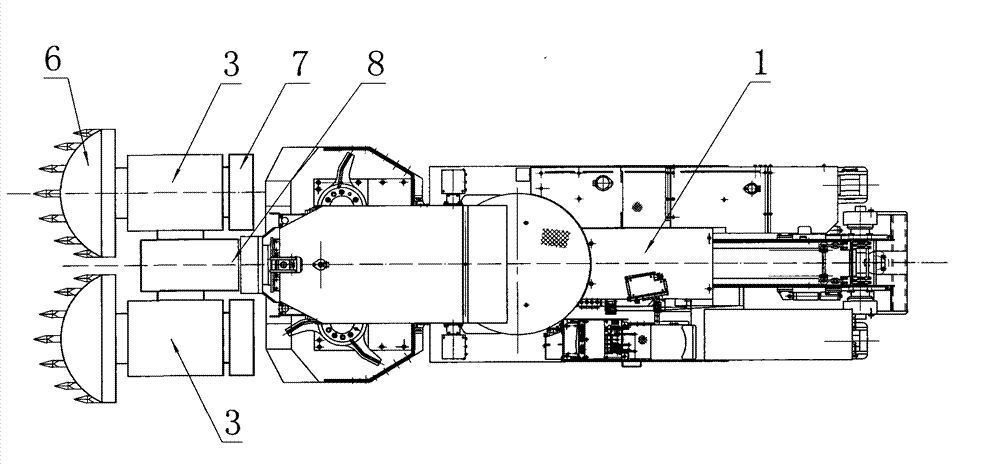

[0556] like Figure 4 to Figure 5 As shown, an anti-wear impact mining machine, the rolling friction impact mining machine includes a fuselage 1, a walking part 2, a reciprocating impact part 3, etc., the reciprocating impact part 3 includes a guide device 5, an impact drive device 4, etc., the guide device 5 Integrated with the impact drive device 4, the guide device 5 includes an impact guide 5.1, a guide rolling body 5.3, a guide support 5.2, etc., the guide roll 5.3 is arranged between the guide support 5.2 and the impact guide 5.1, and the impact guide Impact heads 6 etc. are arranged at both ends of 5.1, the impact head 6 and the impact guide 5.1 are integrated, the impact drive device 4 includes the power impact 4.1, etc., the power impact 4.1 drives the impact guide 5.1 to reciprocate, and the impact guide 5.1 drives The impact head 6 impacts the coal wall or rock wall to realize the mining and falling of materials. The power impact part 4.1 and the impact guide part 5...

Embodiment 3

[0568] like Figure 6 to Figure 7 As shown, an anti-wear impact mining machine includes a fuselage 1, a walking part 2, a lifting device 9, a reciprocating impact part 3, etc., the reciprocating impact part 3 includes a guide device 5, an impact drive device 4, etc., and the impact drive device 4 includes Crank impact drive device 4.2 or hydraulic impact drive device or pneumatic impact drive device, etc., crank impact drive device 4.2 or hydraulic impact drive device or pneumatic impact drive device includes power impact member 4.1, etc., guide device 5 includes guide support member 5.2, impact guide Part 5.1, guide rolling body 5.3, etc., the guide rolling body 5.3 is set between the guide support 5.2 and the impact guide 5.1, the impact head 6 is set at one end of the impact guide 5.1 and the other end is set to prevent the impact head 6 from being separated due to gravity imbalance The guiding device 5, the impact driving device 4, the lifting device 9 and / or the counterwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com