Spinning coal mining machine

A technology for a shearer and a fuselage, which is applied in the field of rotary impact shearers, can solve the problems of reduced productivity and block rate, complex and huge structure, large power consumption, etc., and achieves improved work efficiency, good working environment, and power consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

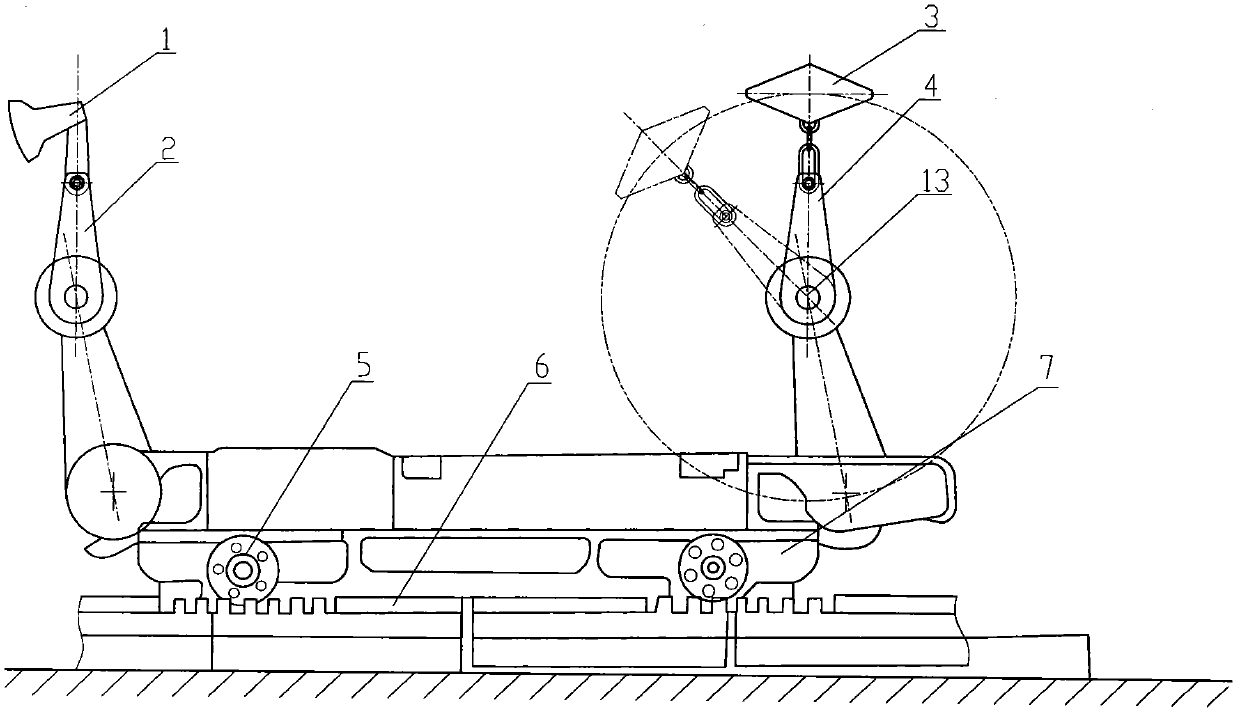

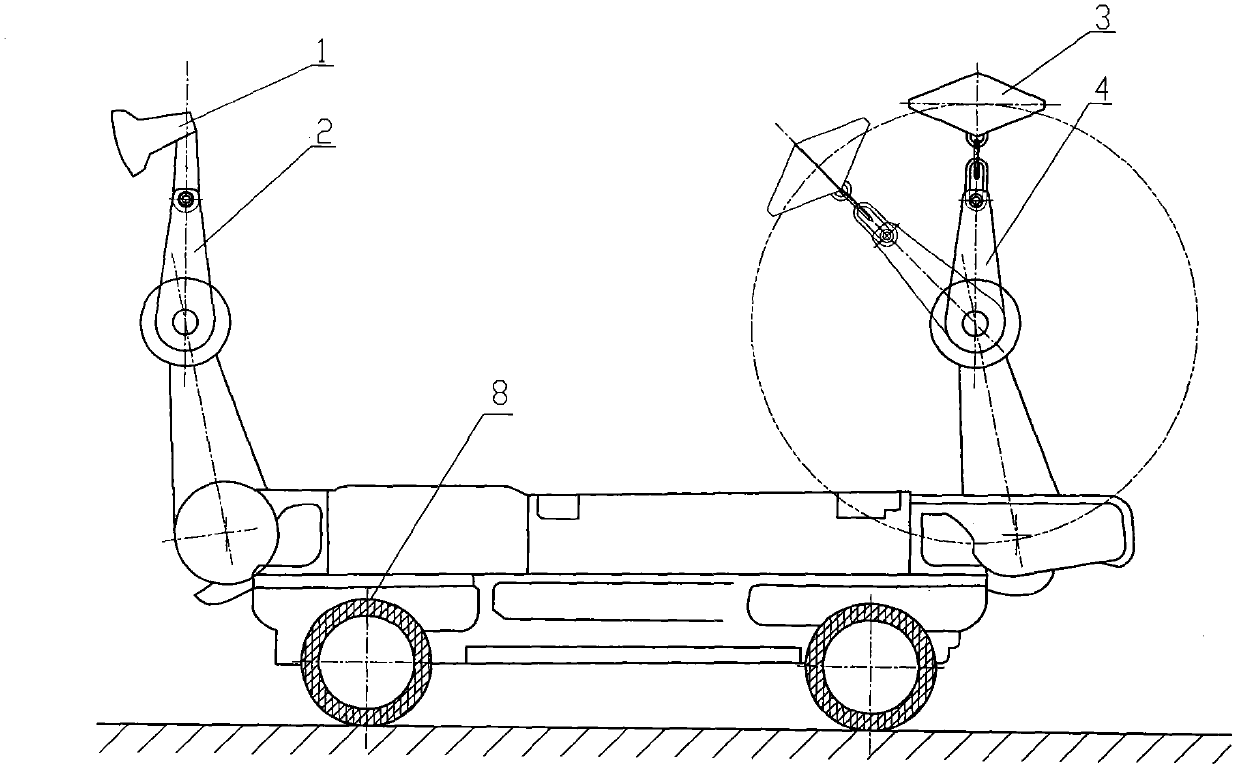

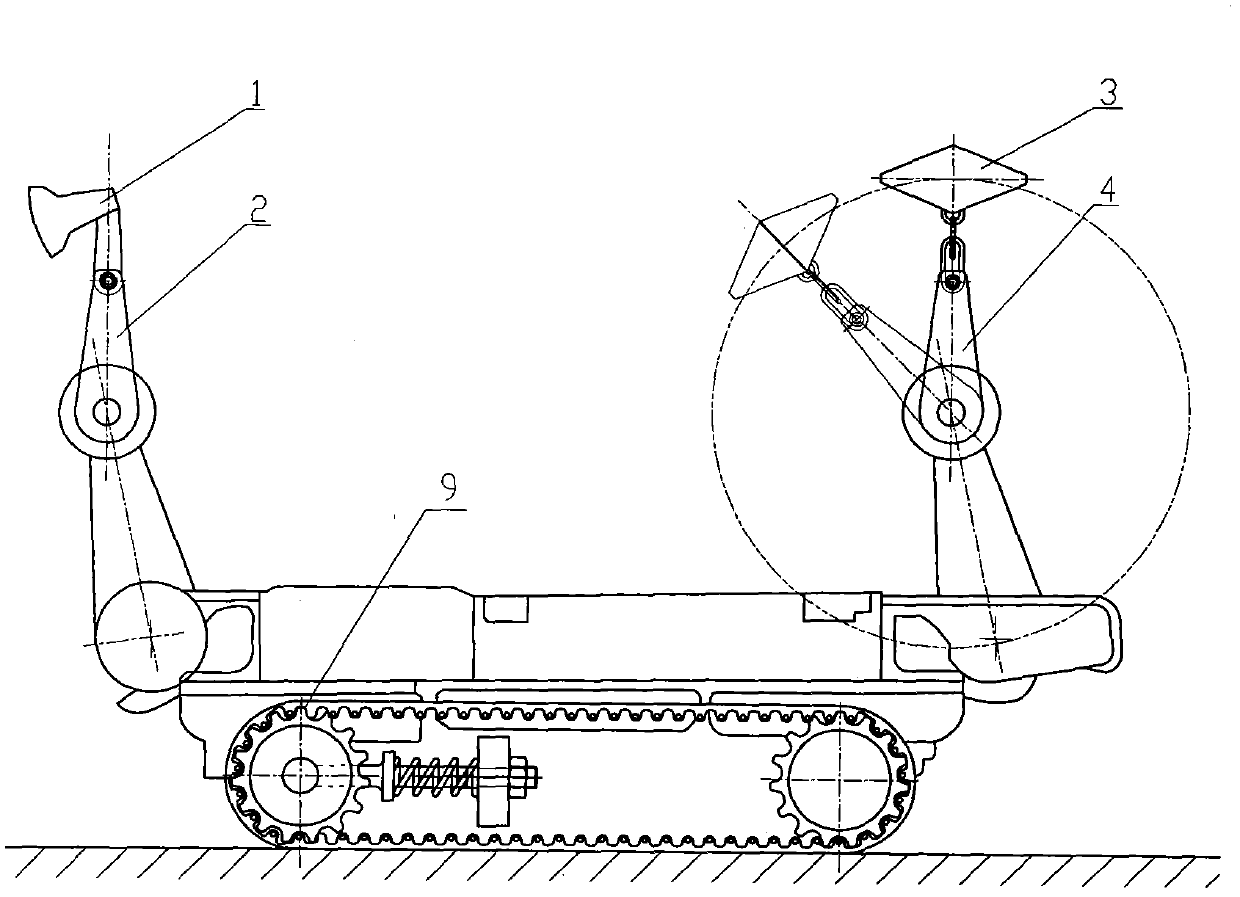

[0031] figure 1 , figure 2 and image 3 It is the rotary percussion shearer described in Embodiment 1. It is composed of a rotary punching mechanism, a driving mechanism and a fuselage. The rotary punching mechanism is installed on the fuselage. The driving mechanism is connected to the rotary punching mechanism. The driving mechanism drives the rotary punching mechanism to rotate. The rotary punching mechanism impacts and cuts the coal seam. device, control device, loading guide device, anti-skid device, dragging cable device, spray device, traction mechanism 7, drive and / or cooling system, etc., traction mechanism 7 pulls the fuselage to walk, and the walking process of the fuselage is related to the rotary punching mechanism The depth of the impacting coal seam is matched and followed up. The body drives the rotary punching mechanism to work and walk. The rotary punching mechanism is installed on the adjustment device. The control device controls the adjustment device to...

Embodiment 2

[0038] like Figure 4 As shown, the punching part of the rotary punching mechanism is the rotary hammer 3, and the hammer heads of the rotary hammer 3 are symmetrically arranged, and the rotary punching mechanism is controlled by the rotation speed and direction control mechanism to control the forward and reverse rotary punching , to achieve forward and reverse coal mining, the control mechanism controls the rotation speed to regulate the depth and volume of coal mining by the rotary punching mechanism.

[0039] Rotary pick hammer 3 is made up of pick hammer head, buffer chain 10, connecting shaft 11, swivel shaft arm 12, swivel shaft 13 and punching hammer buffer device 14, and some auxiliary devices can also be added according to its swivel punching needs. The rotating shaft 13 is connected with the driving mechanism and / or the rotating shaft arm 12 at the same time, and the rotating shaft 13 and the rotating shaft arm 12 rotate simultaneously under the drive of the driving...

Embodiment 3

[0043] like Figure 5Shown is a schematic structural view of the rotary hammer 17, which is connected to the buffer chain 10. The rotary shaft 13 rotates to drive the rotary punching pick 17 for rotary punching coal seam blanking and surface cleaning.

[0044] Others are with embodiment 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com