Coal mining method and coal mining apparatus implementing same

A coal mining method and equipment technology, which is applied in the direction of earthwork drilling, discharge machinery, etc., can solve the problems of enlarged prefabricated holes, low block content rate, and increased energy loss, so as to reduce equipment damage and improve coal mining. The effect of improving efficiency and block rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

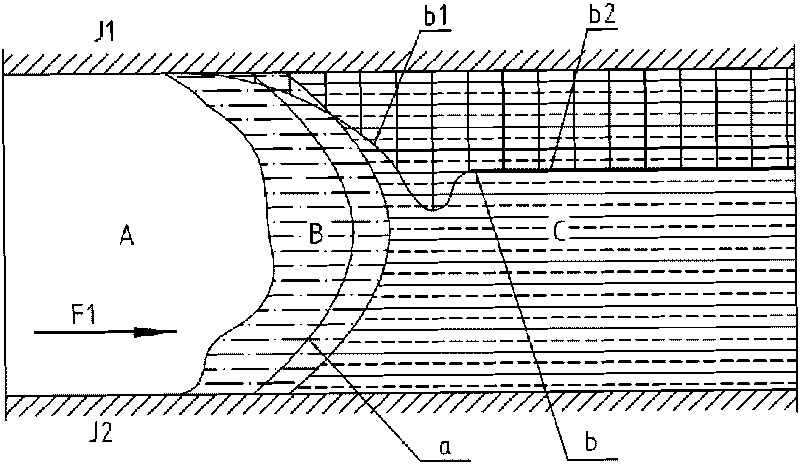

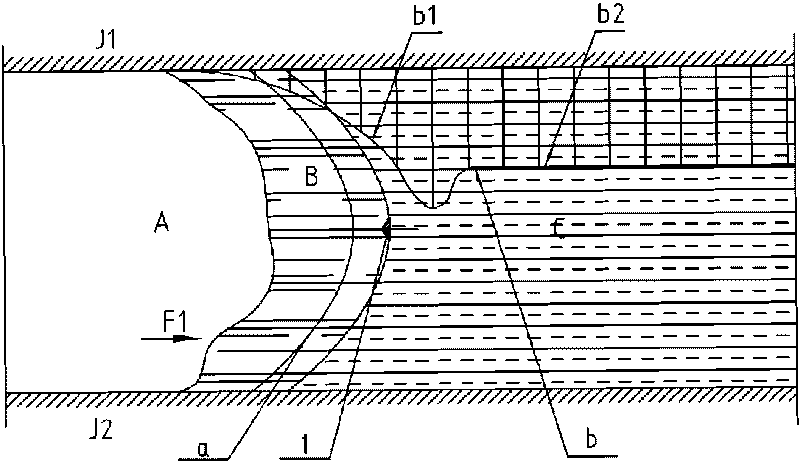

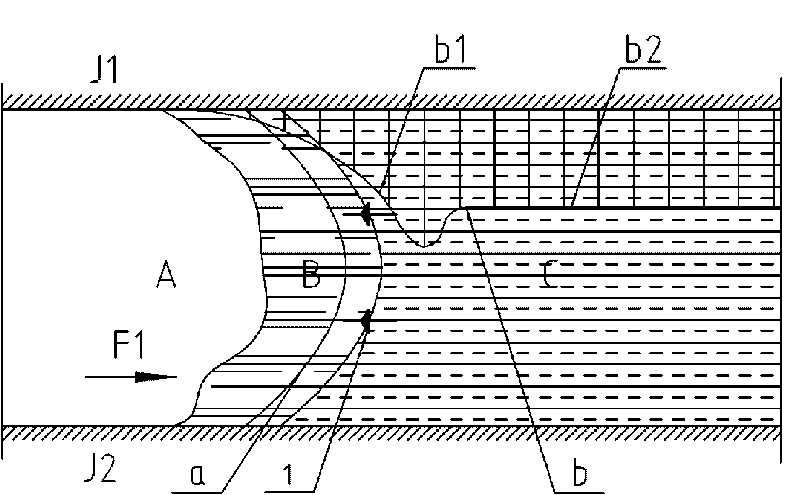

[0039] like Figure 1 to Figure 6 As shown, the curve b is the ground pressure stress curve of the coal body in the excavation cross-section, and the b2 part far from the goaf is less affected by the working face, and the ground pressure stress is almost unchanged along the horizontal direction. The geocompressive stress in the b1 section near the goaf increases suddenly, then gradually decreases, and then shrinks to 0 near the goaf. Figure 5 is the schematic diagram of the ground pressure stress of the longitudinal section of the coal body currently taken, and d is the ground pressure stress curve of the coal body currently taken. The position d2 far away from the goaf is less affected by the working face, and the ground pressure stress is almost unchanged along the horizontal direction. The compressive stress of the d1 part near the coal mining head gradually shrinks until it becomes 0.

[0040] Curve a is the isobaric curve of the ground pressure residual stress of the co...

Embodiment 2

[0053] like Figure 14 and 15 As shown, the equipment is a coal mining equipment similar to a plow, which includes a coal mining head and an auxiliary mechanism. The coal mining head includes two wedge-shaped bodies 1, a bracket 4, a plow plate 5 and a vibrator 6, Wedge body 1, plow plate 5 and vibrator 6 are all installed on the support 4, top plate cleaning mechanism 3 and bottom plate cleaning mechanism 2 are respectively fixed on the top plate and bottom plate at the front end of plow plate 5, top plate cleaning mechanism 3 and bottom plate cleaning mechanism 2 are zigzag-shaped, and the front end of the plow plate 5 is also zigzag-shaped, and is connected to the vibrator 6 together with the wedge-shaped body 1. The vibrator 6 provides additional impact force for the wedge-shaped body 1, and the purpose is to provide stronger mechanical force to facilitate the insertion of the wedge-shaped body 1 into the coal body. The wedge-shaped body 1 is installed on the front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com