Self-propelled coal sawing machine for longitudinally cutting coal bed into block coal and cutting method for cutting coal bed by using machine

A technology of longitudinal cutting and coal sawing machine, which is applied in cutting machinery, earth drilling, open-pit mining, etc. It can solve the problems of cumbersome operation, low coal lumping rate, and low efficiency, so as to improve economic value, cut coal, etc. The effect of high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

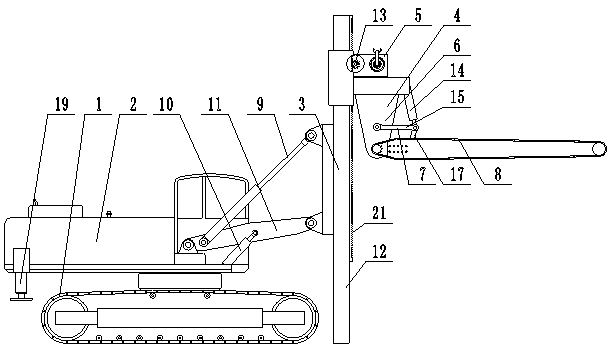

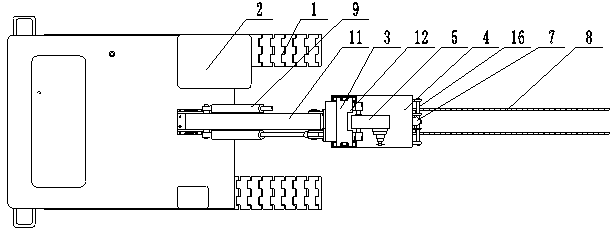

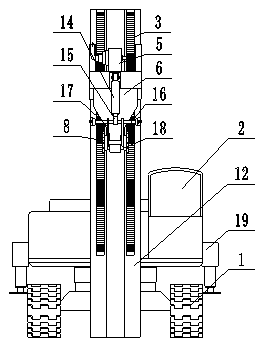

[0031] Such as figure 1 — Figure 4 As shown, the present invention is a self-propelled coal sawing machine that longitudinally cuts the coal seam into lump coal, including a traveling mechanism 1, an operating mechanism 2, a guiding mechanism 3 and an executing mechanism 4, and the operating mechanism 2 is arranged on the traveling mechanism 1. The operating mechanism 2 can reciprocate and rotate 360° on the walking mechanism 1. The guiding mechanism 3 is hinged on the operating mechanism 2. The guiding mechanism 3 can be stretched out or retracted according to whether it is working. The actuator 4 is movable on the guiding mechanism 3. , the actuator 4 can reciprocate up and down along the guide mechanism 3;

[0032] The structure of the executive mechanism 3 is: comprising a driving device 5 and a milling machine driving head 6, the driving device 5 is movably arranged on the guide mechanism 3, the driving device 5 bottom is hinged with a milling machine driving head 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com