Temperature-resistant salt-resistant filled flow regulation particle and preparation method thereof

A temperature-resistant, salt-resistant, and flow-regulating technology, which is applied in the direction of chemical instruments and methods, and drilling compositions, can solve problems that cannot be used to solve the problem of water channeling in reservoirs, and achieves strong guiding significance and good heat resistance , The effect of slow water expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] According to another aspect of the present invention, the present invention also provides a method for preparing the above-mentioned temperature-resistant and salt-resistant filled flow-regulating particles, including the following steps:

[0045] 1) According to the above ratio, add water and bentonite into the mixing tank, after mixing evenly, add calcium hydroxide, and stir thoroughly;

[0046] 2) According to the above ratio, add acrylamide, heat to 50-70°C and fill with nitrogen for protection;

[0047] 3) According to the above ratio, add N, N-methylenebisacrylamide and polyurethane, stir and heat to 110-130°C, then add potassium persulfate, and keep the temperature for 1-5 hours;

[0048] 4) According to the above ratio, add solvent oil and petroleum resin to be Ni / γ-Al 2 o 3 The product catalyzed by the catalyst is kept at a constant temperature of 180-240°C and stirred until it is evenly mixed;

[0049] 5) Dried and crushed until the particle size does not e...

Embodiment 1

[0054] The composition of the temperature-resistant and salt-resistant filled flow regulating particles of this embodiment is: D40 solvent oil and petroleum resin pass through Ni / γ-Al 2 o 3 75 parts (weight) of the product obtained after catalyst catalysis, 35 parts of bentonite, 7 parts of calcium hydroxide, 0.3 part of N, N-methylenebisacrylamide, 35 parts of acrylamide, 0.3 part of potassium persulfate, 7 parts of polyurethane, and 40 parts of water. Among them, the ratio of D40 solvent oil to petroleum resin is 55 parts: 20 parts, using 8 parts Ni / γ-Al 2 o 3 The catalyst catalyzes.

[0055] The preparation method is:

[0056] First add water and bentonite to the mixing tank, then add calcium hydroxide, stir well and add acrylamide, heat to 60°C and fill with nitrogen protection, N,N-methylenebisacrylamide, polyurethane, stir and heat to 120°C Finally, potassium persulfate was added, and the temperature was maintained for 2 hours, and then D40 solvent oil and petroleum...

Embodiment 2-5

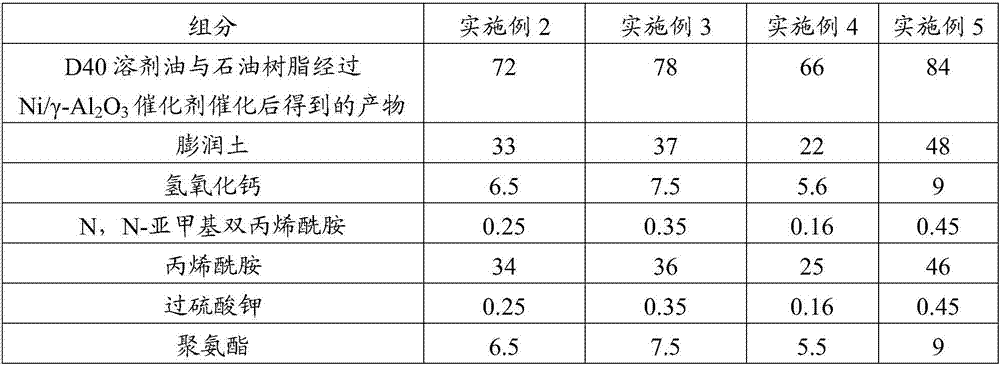

[0058] The composition of the temperature-resistant and salt-resistant filled flow-regulating particles of Examples 2-5 is shown in Table 1. In embodiment 2 and 3, the ratio of D40 solvent oil and petroleum resin is 50 parts: 15 parts, adopts 5 parts of Ni / γ-Al 2 o 3 The catalyst catalyzes. In embodiment 4 and 5, the ratio of D40 solvent oil and petroleum resin is 60 parts: 25 parts, adopts 10 parts of Ni / γ-Al 2 o 3 The catalyst catalyzes. The preparation method of the temperature-resistant and salt-resistant filled flow-regulating particles of Examples 2-5 is the same as that of Example 1.

[0059] The product of the present invention is simulated formation temperature 130 ℃, salinity 20 * 10 4 mg / L oil reservoir conditions, the main performance parameters of the temperature-resistant and salt-resistant filled flow-regulating particles of each embodiment are shown in Table 2.

[0060] The content of each component of the temperature-resistant and salt-resistant filled f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com