Method for coal mine downhole reproduction and back production

A coal mining method and coal mine technology, applied in mine/tunnel ventilation, ground mining, mining equipment, etc., can solve the problems of low degree of mechanization of the working face, low yield per unit area of the working face, and low degree of mechanization, etc. Environmental protection, reduction of workers, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

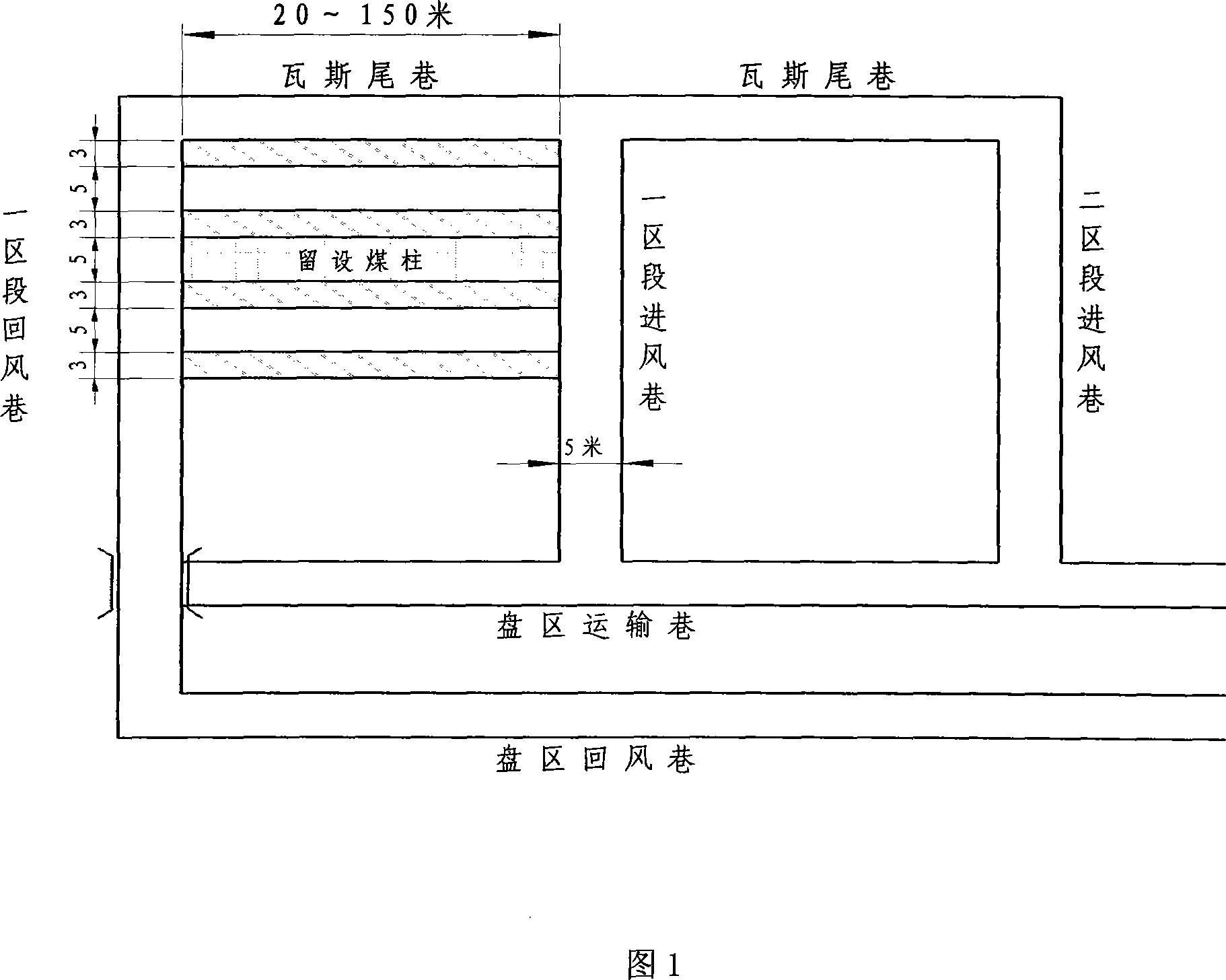

[0030] As shown in Fig. 1, the roadway layout diagram of the method for re-mining and recovering coal in a coal mine of the present invention. The roadway layout is to divide several sections in the panel area, and arrange two preparation roadways in the section, one of which is used as the air inlet lane, and the other is used as the air return lane. As the return air lane of the next section, only one return air lane will be excavated in the next section, and long strip-shaped pillars will be arranged between the two preparation roadways. The long strip-shaped pillars are about 16m wide and 20-150m long. The width of the mining room is arranged to be 4m, the width of the mining pillar is 4+4=8m, and a coal pillar of 5m is left, and a gas tailway is set at the end of the ventilation roadway of each section, and the gas tailway is connected with the ventilation roadway of each section; the remaining coal pillar ensures When the next room pillar is mined, it is carried out unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com