Preparation method of perovskite-structure relaxor ferroelectric single crystal lead indium niobate-lead magnesium niobate-lead titanate

A technology for relaxing ferroelectric single crystal and perovskite structure, which is applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc. Serious segregation, small area of high-performance wafers, etc., to overcome the difficulties of batch growth and application of single crystals, improve wafer competitiveness, and reduce wafer costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

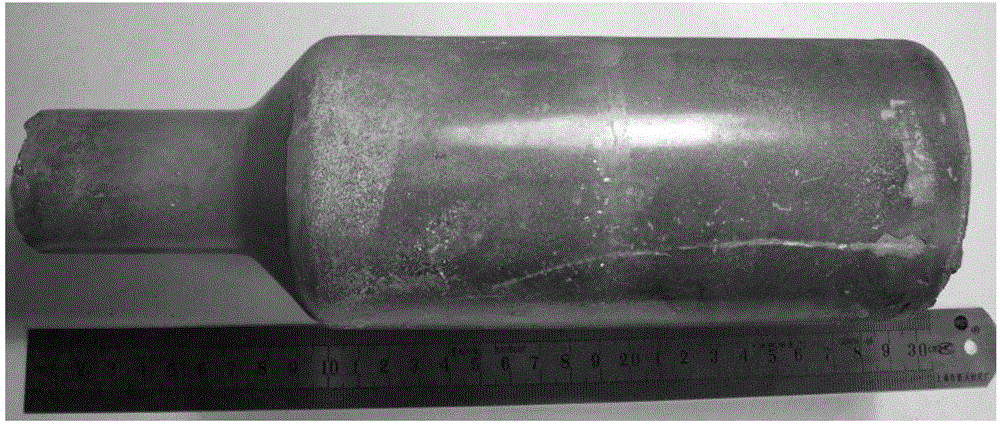

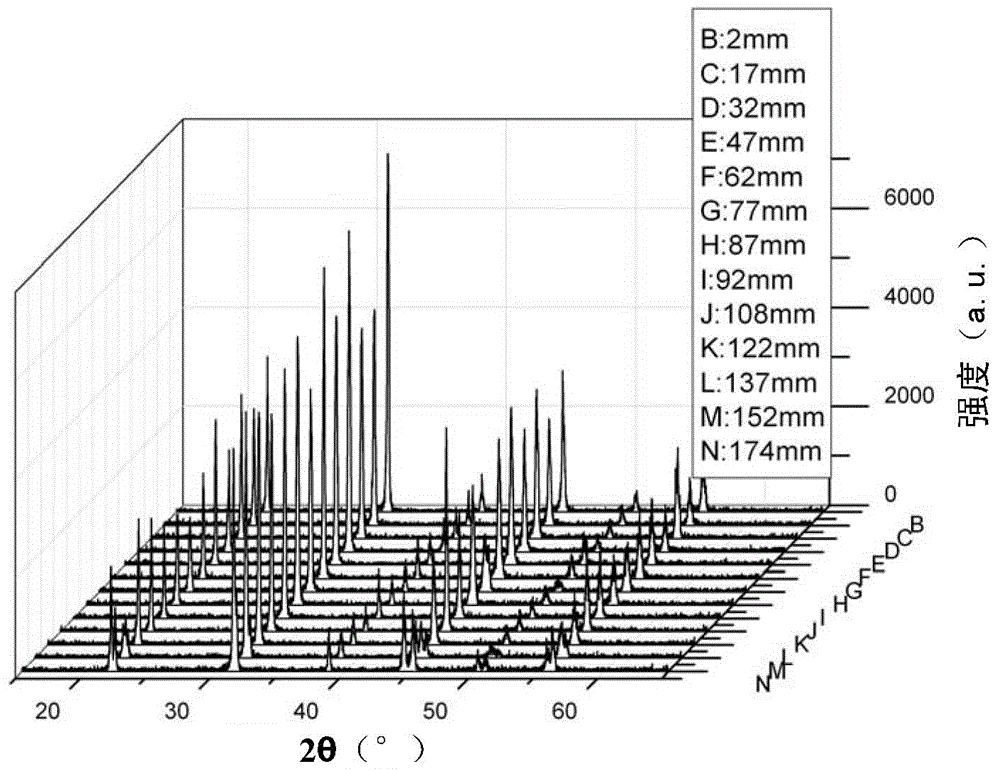

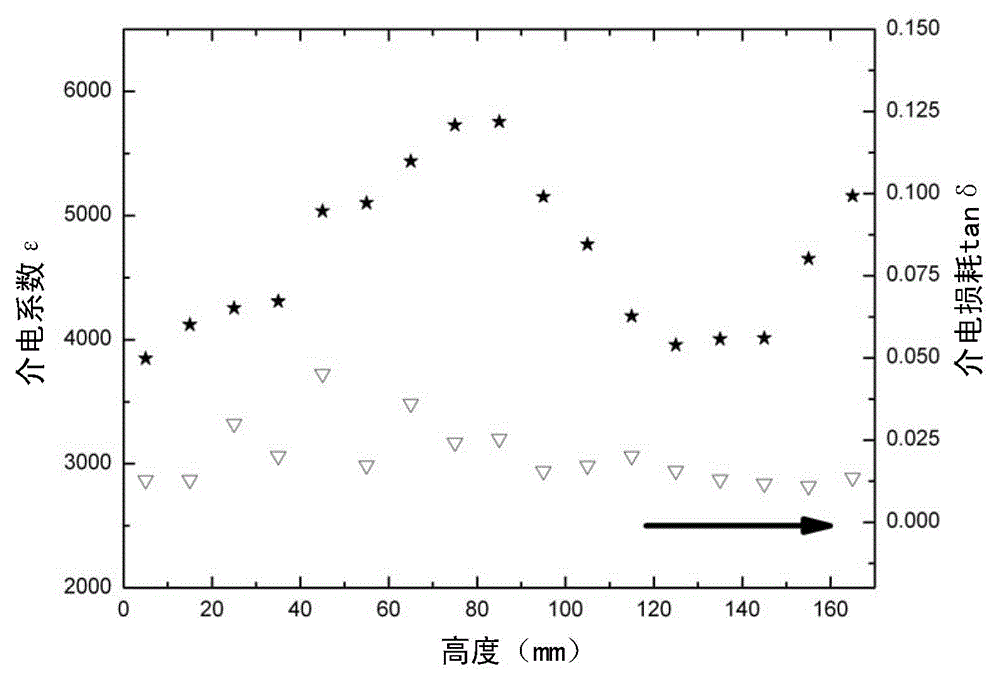

[0035] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the following drawings and / or embodiments are only used to illustrate the present invention rather than limit the present invention.

[0036] The XRD collection of collections involved in the present invention is to obtain with Bruker D8 measurement crystal powder; Piezoelectric coefficient d 33 The ZJ-3A quasi-static piezoelectric coefficient d produced by the Institute of Acoustics, Chinese Academy of Sciences 33 The tester is directly measured; the dielectric properties are obtained by measuring the sample capacitance with the Agilent4294A impedance analyzer, and are obtained by approximate calculation based on the plate capacitor; the electromechanical coupling coefficient is based on the IEEE176-1987 standard, and the impedance spectrum is measured with the Agilent4294A impedance analyzer, according to Resonant frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com