A semi-continuous casting method and device for air pressure filling

A semi-continuous, mold-filling technology, applied in the field of metal material molding, can solve the problems of limited effect of grain refinement, limited effect of grain refinement, rising equipment investment cost, etc., to eliminate coarse columnar crystals and suppress macroscopic components Effect of segregation and promotion of crystal nucleus dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

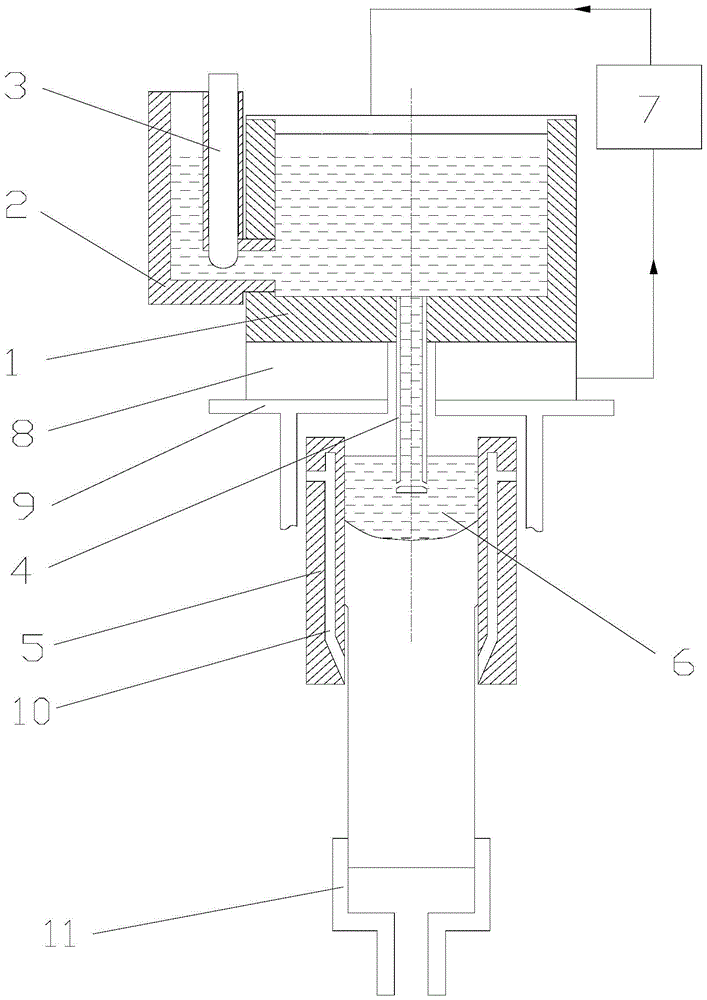

[0035] This embodiment is a semi-continuous casting method for air pressure filling. By setting a sprue between the tundish and the crystallizer, and controlling the flow rate of the molten metal at the outlet of the sprue, the convection of the molten metal in the liquid cavity is strengthened. effect and agitation to refine the crystals in the ingot.

[0036] The flow rate control of the molten metal at the outlet of the sprue is realized by adjusting the gas pressure in the tundish. The flow rate of the molten metal at the outlet of the sprue and the gas pressure in the tundish satisfy the following relationship:

[0037] v = D 2 nd 2 2 Hg + 2 P ρ ,

[0038] In the formula: v is the flow rate of the molten metal at the o...

Embodiment 2

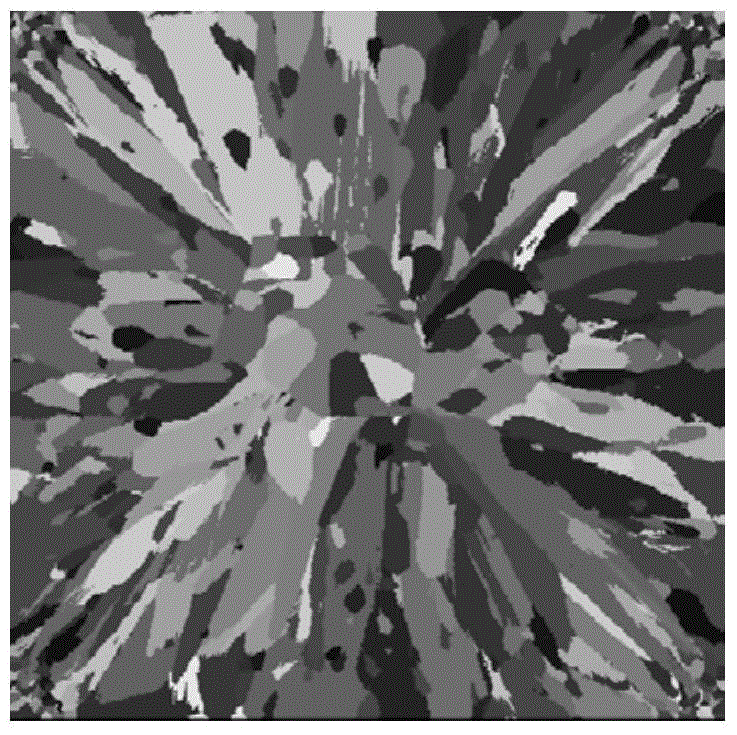

[0049] In this embodiment, the copper-nickel-tin alloy is a solid solution alloy with a wide crystallization temperature. During slow cooling, thick dendrites tend to appear in the ingot structure, and the Sn solute tends to move outward along the dendrites. A reverse segregation of tin is formed.

[0050] The first: utilize the semi-continuous casting method and device of embodiment 1, take following process:

[0051] (1) The alloy composition is Cu-15Ni-8Sn. The ingot specification is φ180mm.

[0052] (2) The technological parameters in the casting process are as follows: the pouring temperature is 1250-1260°C, the ingot pulling speed is 1.6mms / s, the cooling water pressure is 0.06MPa, and the pressurized gas is argon.

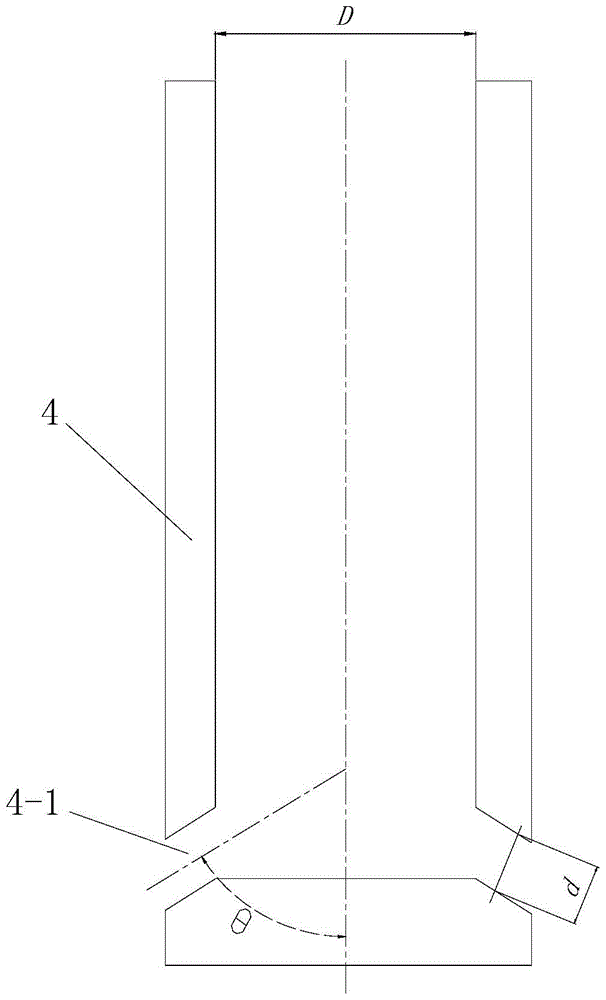

[0053] (3) The diameter D of the inlet of the sprue is 3.7mm, and the diameter d of each opening at the outlet of the sprue is 1.5mm. There are 6 openings in total. The angle θ between the center line of the sprue and the center line of each opening is 60...

Embodiment 3

[0060] In this embodiment, the copper-nickel-tin alloy is a solid solution alloy with a wide crystallization temperature. During slow cooling, thick dendrites tend to appear in the ingot structure, and the Sn solute tends to move outward along the dendrites. A reverse segregation of tin is formed.

[0061] The first: utilize the semi-continuous casting method and device of embodiment 1, take following process:

[0062] (1) The alloy composition is Cu-15Ni-8Sn-0.35Ti. The ingot specification is φ350mm.

[0063] (2) The technological parameters in the casting process are as follows: the pouring temperature is 1250-1260°C, the ingot pulling speed is 1.1mms / s, the cooling water pressure is 0.1MPa, and the pressurized gas is argon.

[0064] (3) The diameter D of the inlet of the sprue is 9.8mm, the diameter d of each opening at the outlet of the sprue is 4mm, and there are 6 openings in total, and the included angle θ between the center line of the sprue and the center line of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com